High-speed separation ultrasonic vibration cutting control method

A technology of ultrasonic vibration cutting and control method, which is applied in the direction of automatic control device, program control, digital control, etc., can solve the problem that the requirements of high-speed cutting and surface roughness cannot be met at the same time, the processed surface is rough, and the surface roughness does not meet the requirements. etc. to achieve the effect of reducing the deterioration of surface roughness, satisfying high-speed cutting, and reducing the residual height of pits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

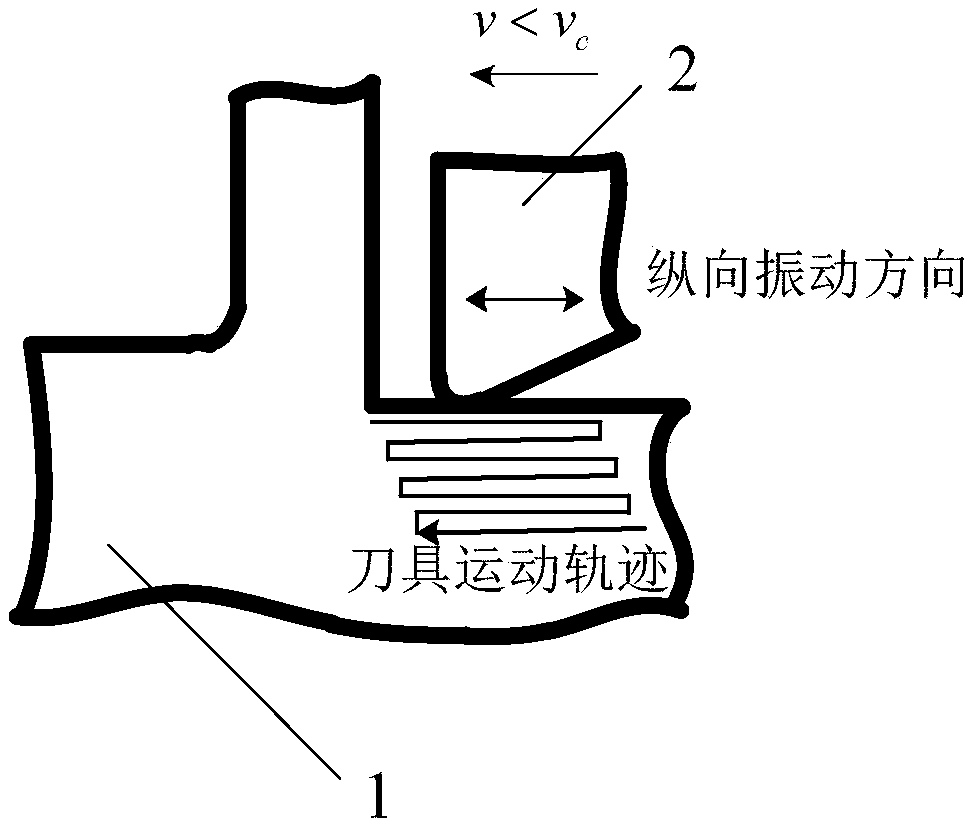

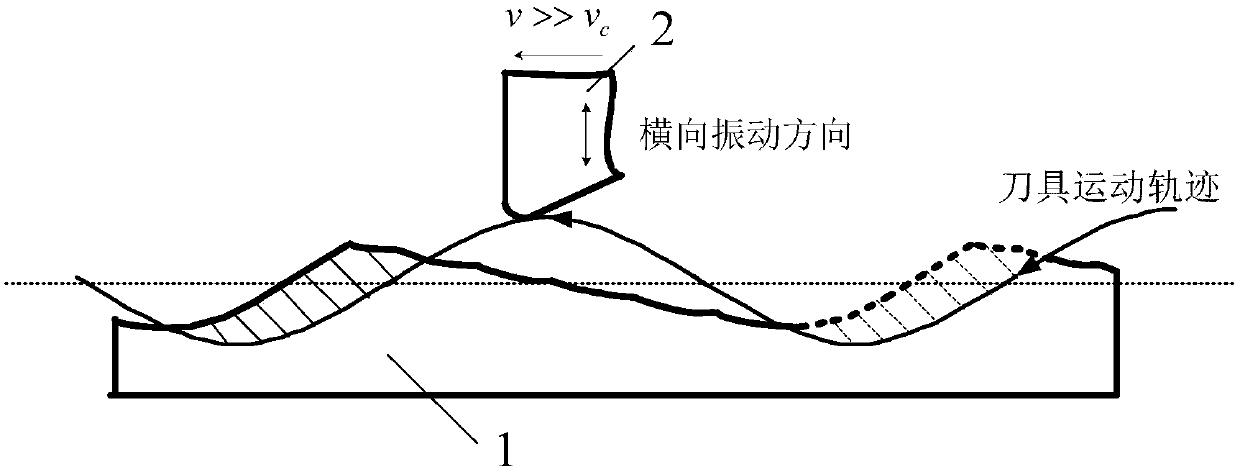

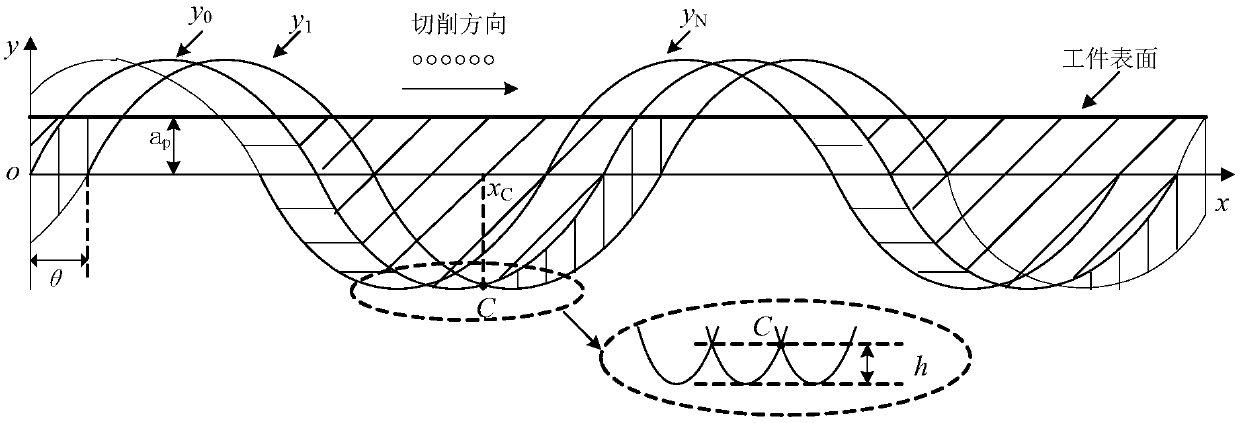

[0051] refer to Figure 3-Figure 8 , in this embodiment, a high-speed separation ultrasonic vibration cutting control method is provided, wherein an ultrasonic vibration cutting device including a closed-loop DDS is used to control the vibration direction of the tool 2 to be perpendicular to the cutting speed direction or to have a component perpendicular to the cutting speed direction, That is, control the tool 2 to perform vibrations including vibrations perpendicular to the cutting speed direction during the cutting process (including only lateral vibrations and lateral vibration components). when the condition a pWhen (cutting depth) image 3 y in 0 and y 1 The pit dislocations and overlaps caused by lateral vibration in the corresponding two tool motion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com