Noodle steaming device

A steaming and vermicelli technology, which is applied to steam cooking utensils, etc., can solve the problems of poor quality, thickness or taste of vermicelli, unreasonable setting of the outlet of the barrel, and inability to ensure the thickness of vermicelli, so as to improve the cooking effect, reasonable cooking, Guarantee the effect of quality and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0038] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

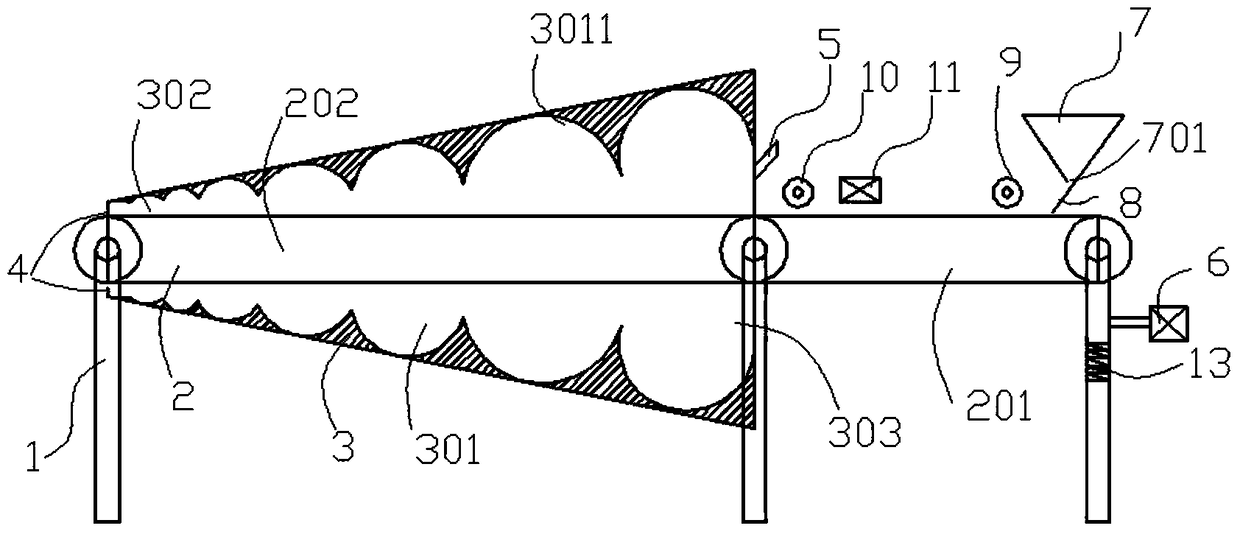

[0039] The present invention is based on such principle: as figure 1 As shown, the steam input direction is opposite to the moving direction of the conveyor belt 2, which can increase the contact time between the slurry and the steam on the conveyor belt 2 and the efficiency of heat exchange, and improve the utilization rate of steam. The end gradually decreases, so the cooking of the slurry forms a gradient. When the slurry is input, the temperature is low, and the slurry is in a preheated state. With the operation of the conveyor belt 2, the temperature rises, and the slurry un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com