Sapphire cutting device

A cutting device, sapphire technology, applied in the direction of welding/welding/cutting items, laser welding equipment, manufacturing tools, etc., can solve the problems of replacement of diamond-coated wire, high cutting cost, expensive diamond, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

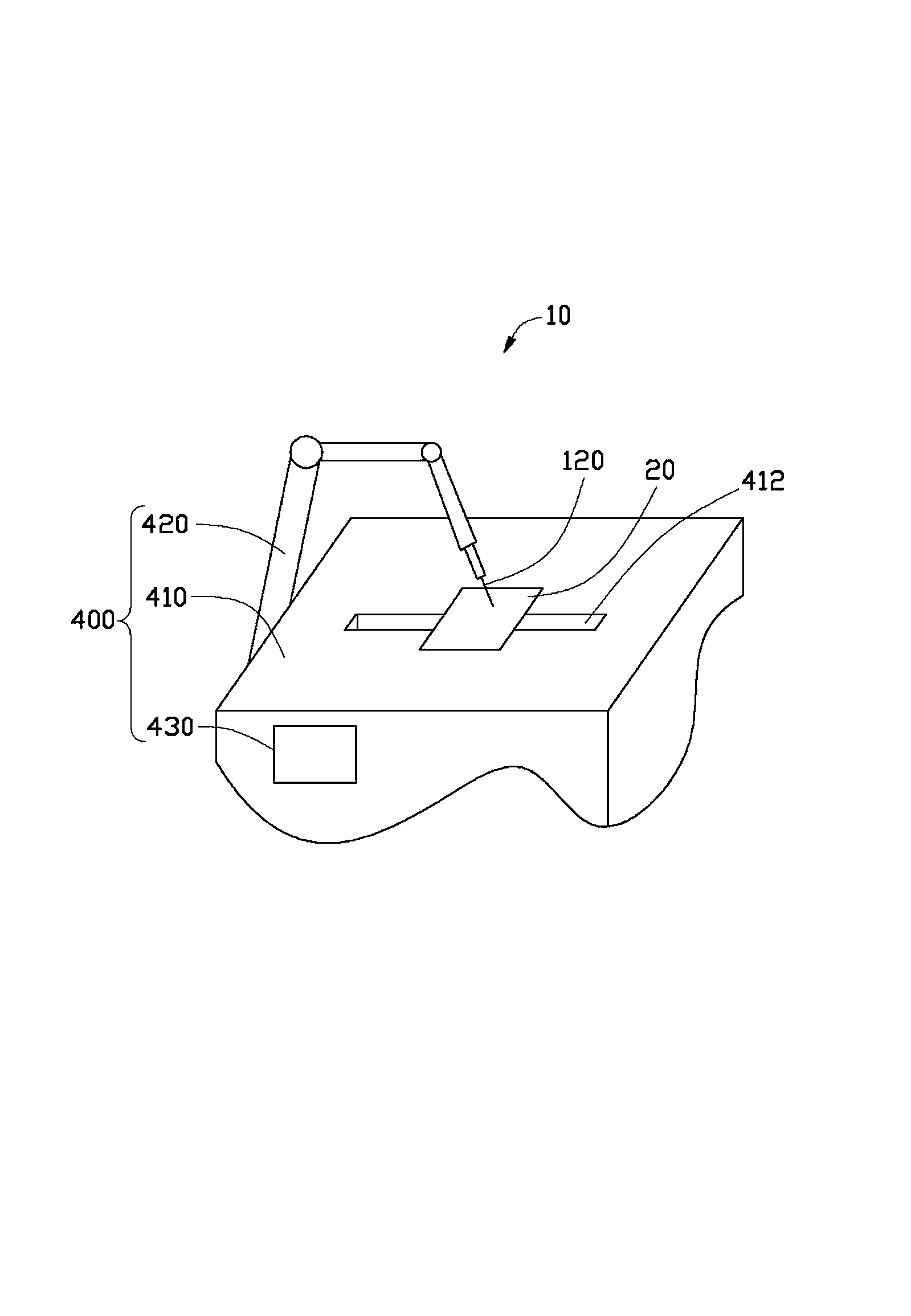

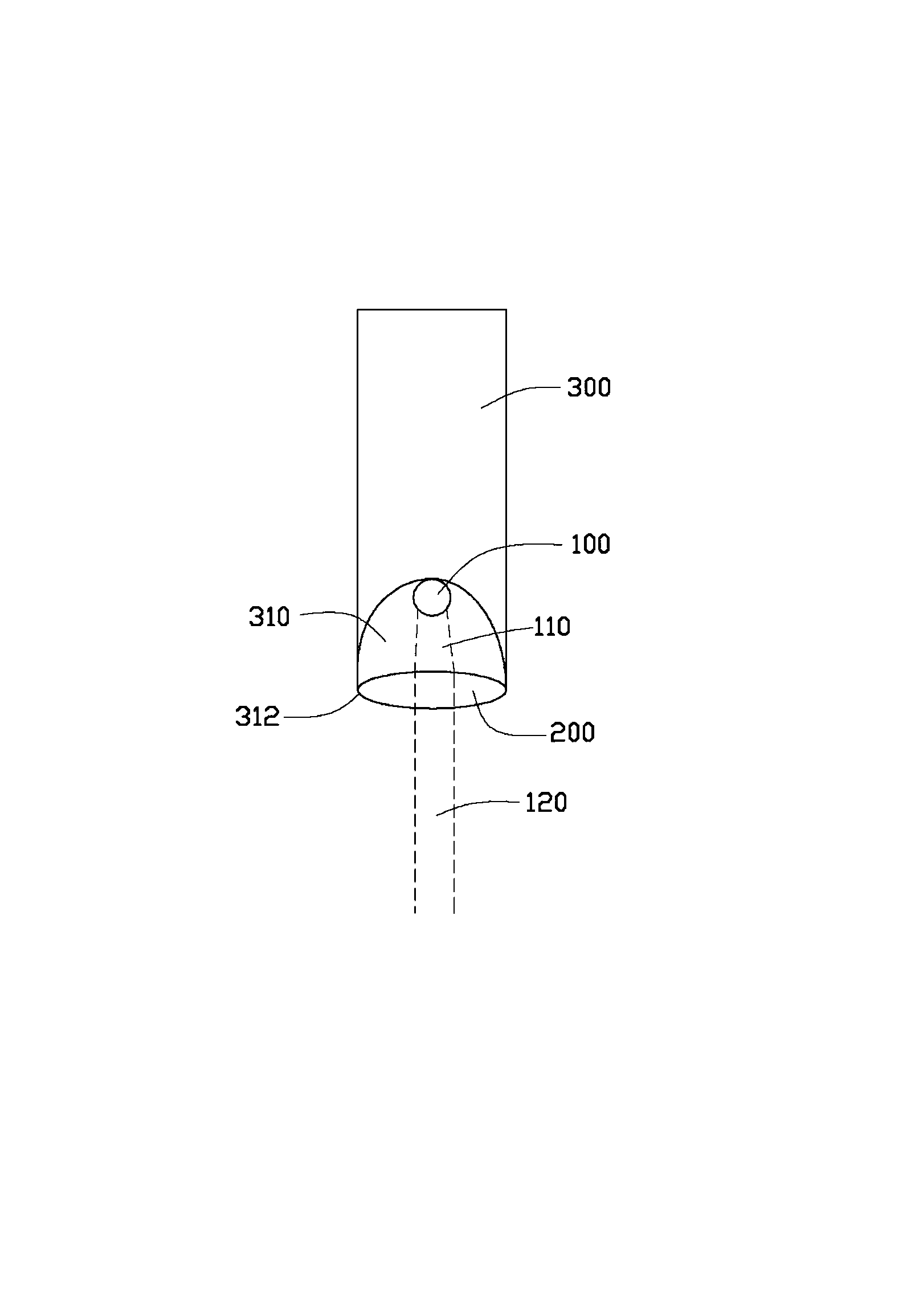

[0011] see Figure 1-2 , the sapphire cutting device 10 according to the preferred embodiment of the present invention includes an ultraviolet laser source 100 and a collimating lens 200 . The ultraviolet laser source 100 is used to emit a laser beam 110 . The collimating lens 200 is used to converge the laser beam 110 into a parallel laser beam 120 . The parallel laser beam 120 is used to cut the sapphire 20 . The working waveband of the ultraviolet laser source 100 is 200-400 nanometers.

[0012] In this way, the cost can be reduced by using the lower-cost ultraviolet laser source 100 and the collimator lens 200 instead of the higher-cost diamond. In addition, laser cutting can achieve high-speed cutting and improve efficiency.

[0013] The ultraviolet laser source 100 is an excimer laser source, or adopts a laser diode or a high-power light-emitting diode.

[0014] The preferred operating wavelength of the ultraviolet laser source 100 is 350-390 nm.

[0015] Specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com