Bearingless fruit picking device for high branches

A bearingless, picker technology, applied in picking machines, agricultural machinery and implements, applications, etc., can solve the problems of difficult positioning of high-altitude sickles, difficulty in precise cutting, low picking efficiency, etc., to reduce the labor intensity of picking and low labor intensity. , good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

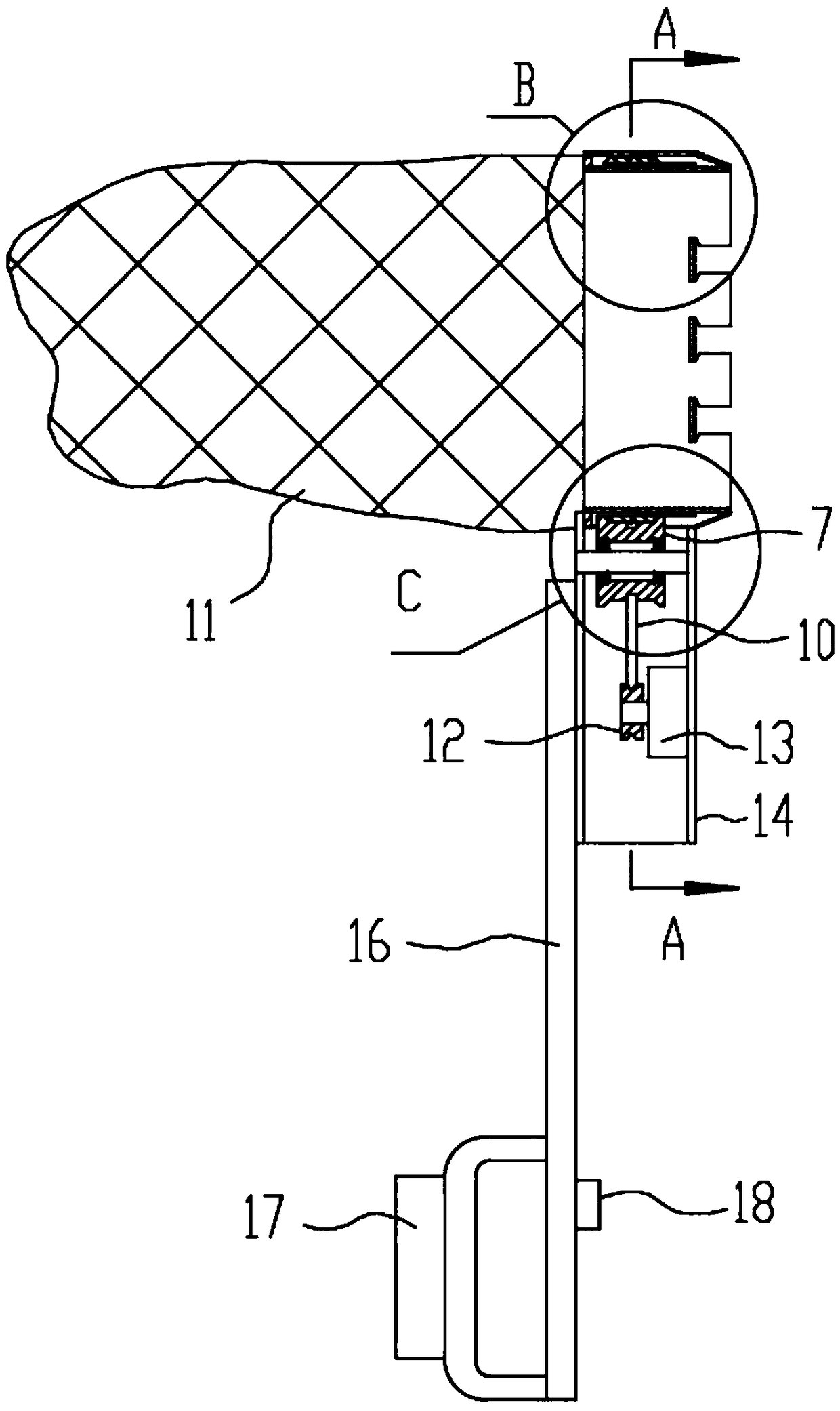

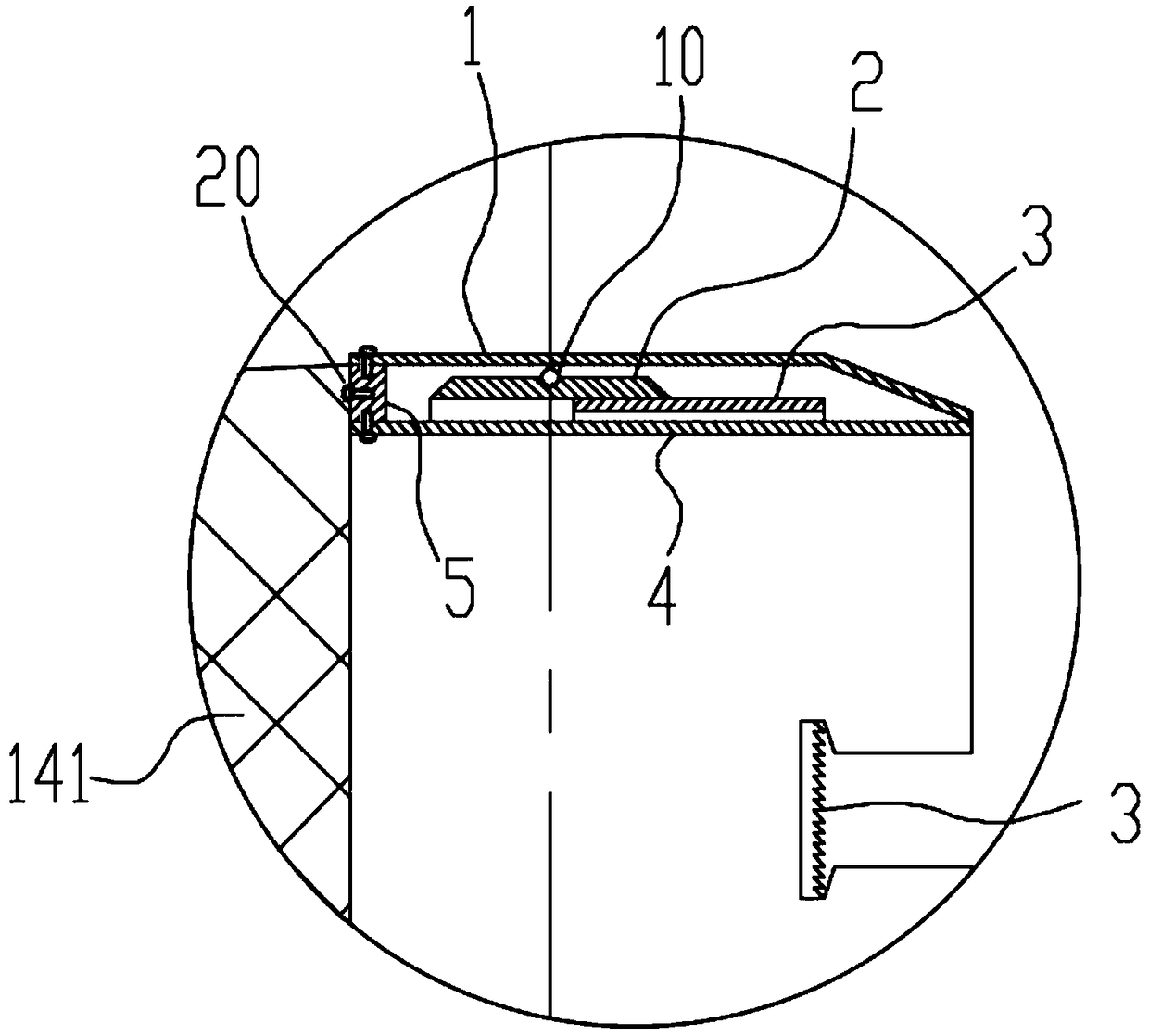

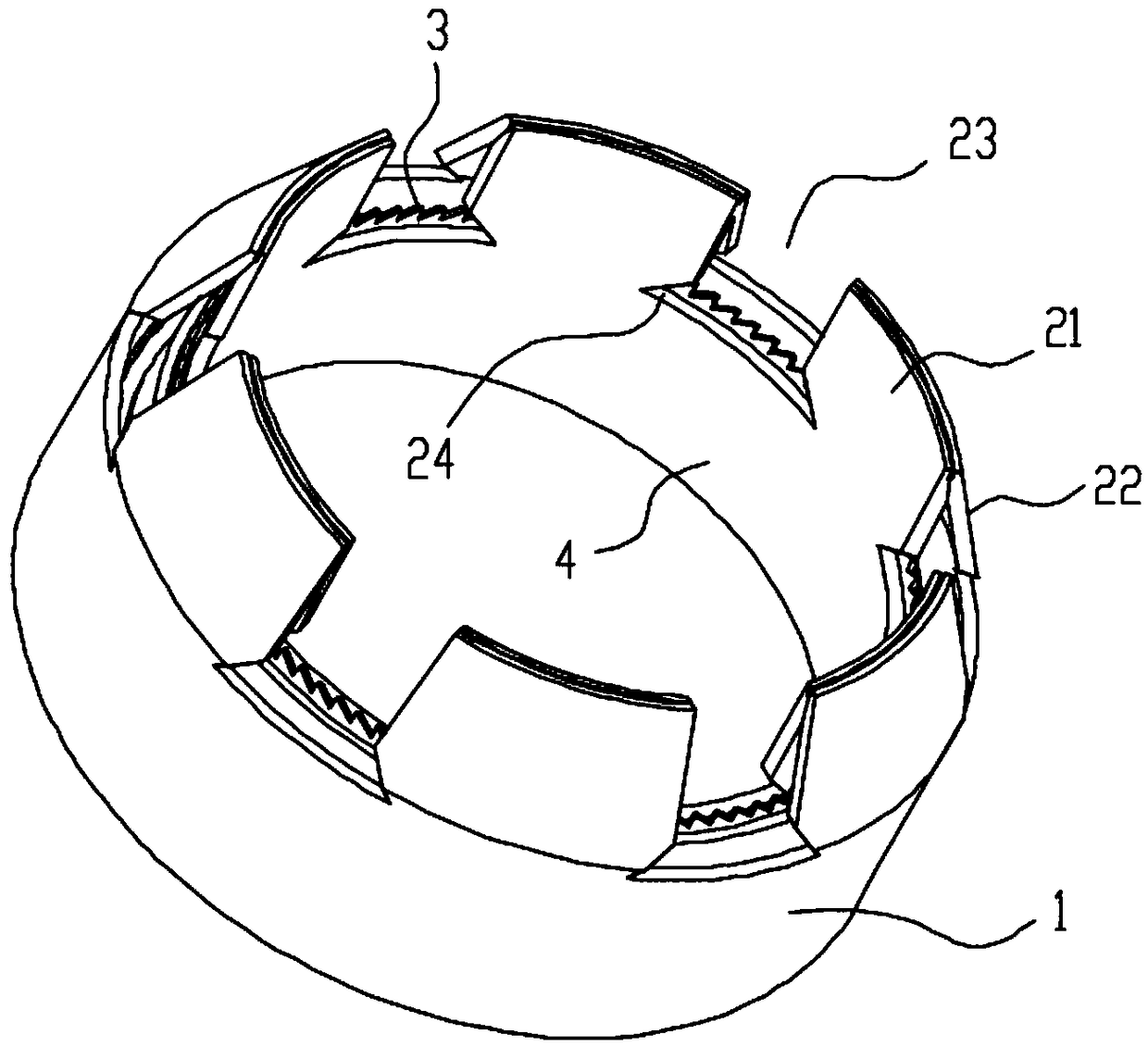

[0034] Such as Figure 1-Figure 8 Shown, the concrete structure of the present invention is: a kind of bearingless high-branch fruit picker, and it comprises telescopic rod 16, and described telescopic rod 16 front end is provided with coaxial outer sleeve 1 and inner sleeve 4 that mutually socket; An annular saw blade 3 is arranged between the outer sleeve 1 and the inner sleeve 4; notches 23 are uniformly arranged on the upper ports of the inner sleeve 4 and the outer sleeve 1; Slot 24; the bottom surface of the triangular groove 24 is flat with the bottom surface of the notch 23; the upper end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com