Fly-cutting system and method, and related tooling and articles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

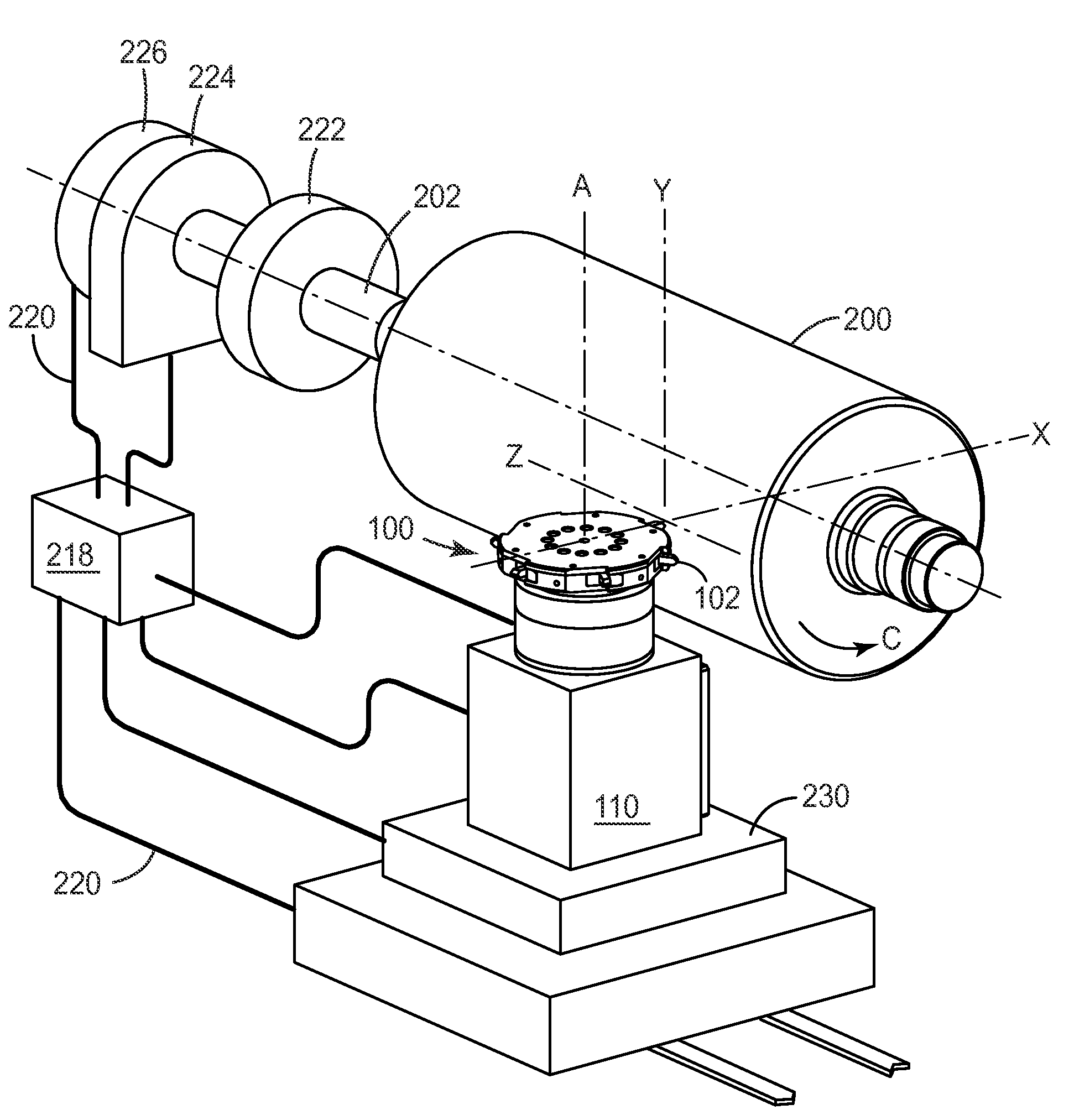

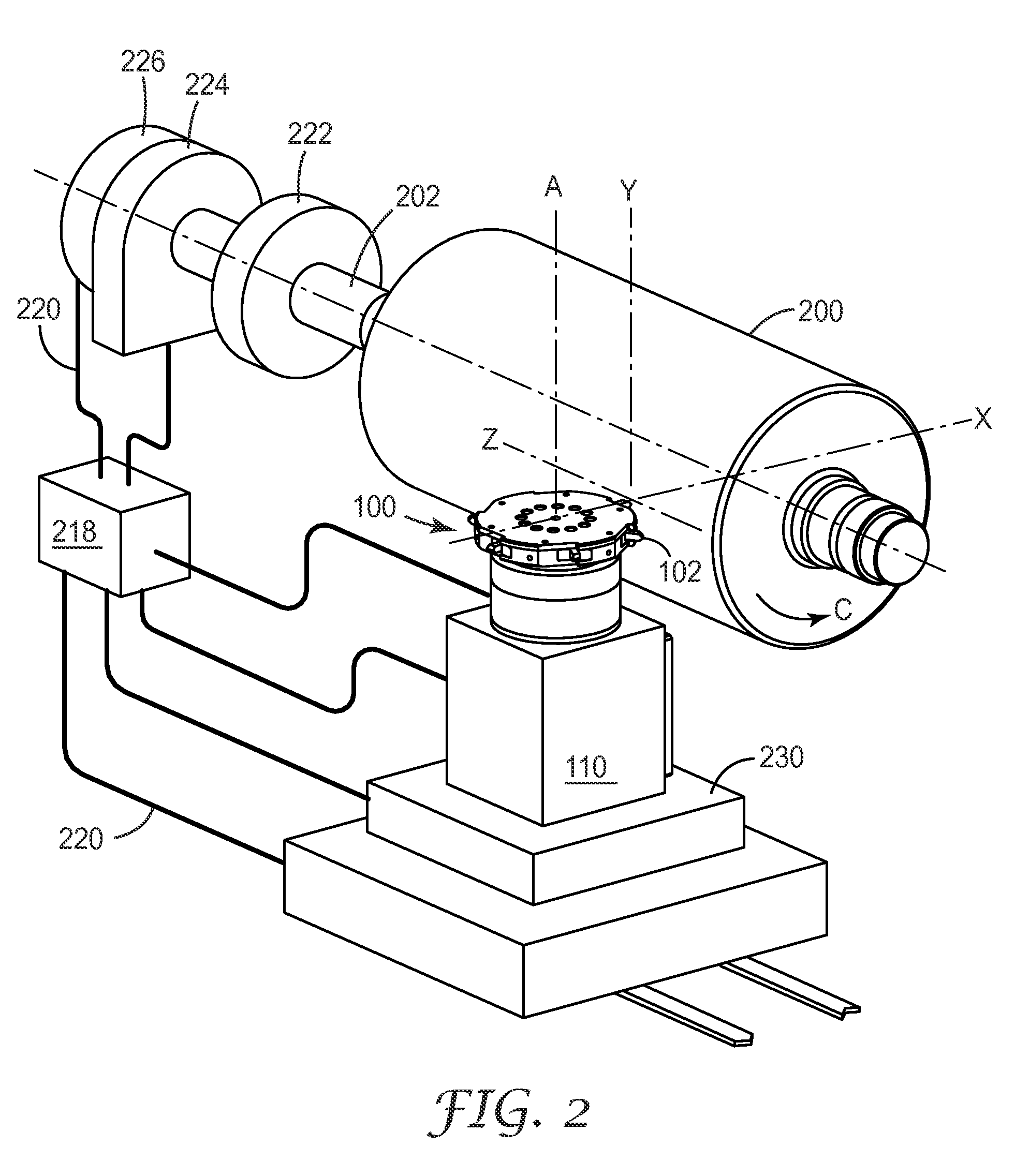

[0025]In conventional fly-cutting operations, a fly-cutter is positioned relative to a workpiece, a motor is activated to rotate the head and the associated cutting element or elements, and the fly-cutting head is moved relative to the workpiece to cut a groove or other feature into the workpiece. Fly-cutting, which is a type of milling, is typically a discontinuous cutting operation, meaning that each cutting element is in contact with the workpiece for a period of time, and then is not in contact with the workpiece for a period of time during which the fly-cutting head is rotating that cutting element through the remaining portion of a circle until it again contacts the workpiece. Although a fly-cutting operation is typically discontinuous, the resulting groove segment or other surface feature formed in a workpiece by the fly-cutter may be continuous (formed by a succession of individual, but connected cuts, for example) or discontinuous (formed by disconnected cuts), as desired. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com