Method for preparing superfine titanium carbonitride

A technology of titanium carbonitride and carbon source, which is applied in the field of preparation of ultrafine titanium carbonitride, can solve the problems of complex equipment, high product quality, high cost of raw materials, difficulty in obtaining high-purity and high-quality TiCN powder, and facilitate large-scale industrial production. The effect of production, high product quality and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

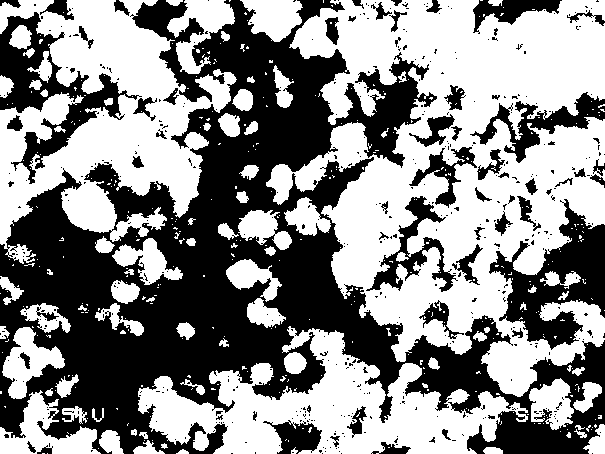

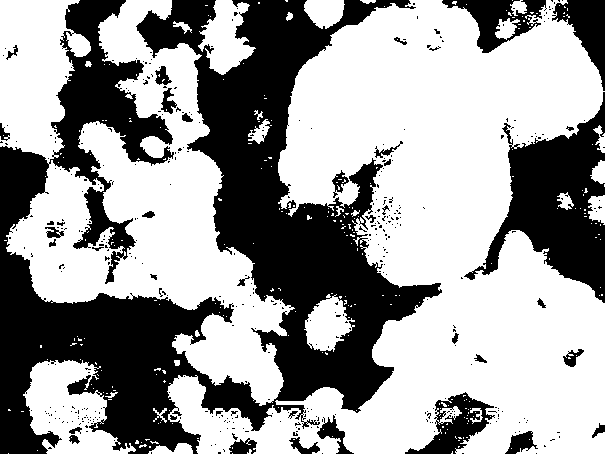

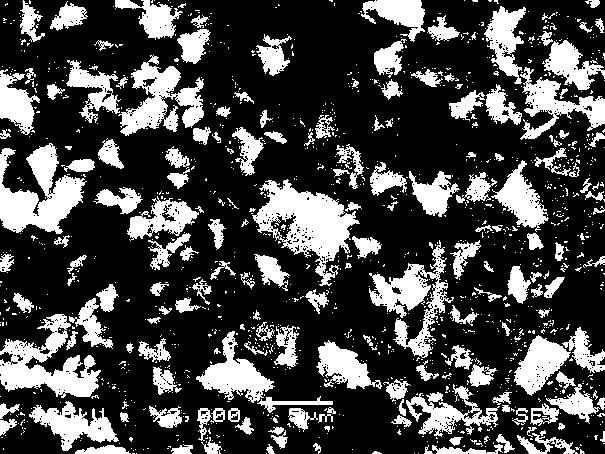

[0028] A method for preparing ultra-fine titanium carbonitride, using TiO 2 and starch as raw material, 100kg TiO 2 Mix evenly with 87.5kg starch (in which nano TiO 2 The mass ratio of carbon contained in the organic carbon source is 10:3.85), cold pressed into blocks, put into a vacuum furnace, heat up rapidly at a speed of 5°C / min, and vacuumize at the same time to make the vacuum degree less than 50Pa, when After the temperature rises to 700°C, keep it warm for 1 hour, then continue to rise to 1500°C, keep it warm for 2 hours, then stop vacuuming, feed nitrogen continuously to make the pressure in the furnace 1.1 atmospheres, and stop heating after nitriding at 1500°C for 2 hours , so that the product is cooled with the furnace. The TiCN content of the product is 99.2%, the O content is 0.9%, the Fischer particle size is 0.93um, the SEM appearance is spherical, and the particle size distribution is uniform. See figure 1 , figure 2 . image 3 with Figure 4 It is the ...

Embodiment 2

[0030] A method for preparing ultra-fine titanium carbonitride, using TiO 2 and polyvinyl alcohol as raw material, 100kg TiO 2 Mix evenly with polyvinyl alcohol containing 76.8kg (including nano-TiO 2 The mass ratio of carbon contained in the organic carbon source is 10:4), cold pressed into a block, put into a vacuum furnace, heat up rapidly at a speed of 5°C / min, and vacuumize at the same time to make the vacuum degree less than 50Pa, when After the temperature rises to 650°C, keep it warm for 1 hour, and then continue to rise to 1520°C, keep it warm for 2 hours, then stop vacuuming, and continuously feed nitrogen to make the pressure in the furnace 1.1 atmospheres. After nitriding at 1520°C for 3 hours, stop heating. Allow the product to cool in the furnace. The TiCN content of the product is 99.1%, the O content is 0.8%, and the Fibonacci particle size is 0.96um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com