Mechanical activation-reaction heat treating preparation process of nanometer titanium carbonitride

A titanium carbonitride nanometer, mechanically activated technology, applied in nitrogen compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of limited large-scale production, large product particle size, and high raw material cost, and achieve industrial-scale production. , good dispersion, cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

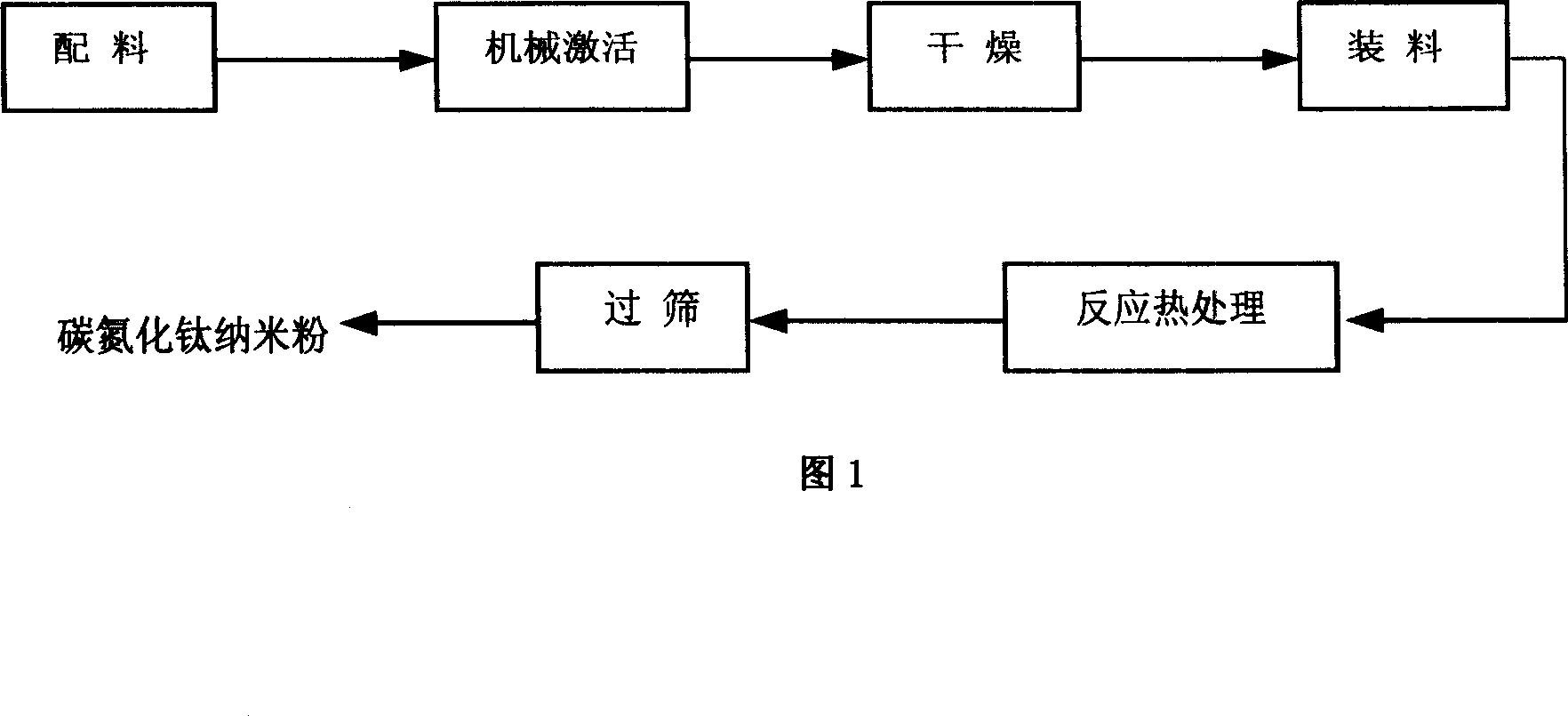

[0032] In the present embodiment, raw material is nano-titanium oxide and nano-carbon powder, has the following process steps according to process flow chart 1:

[0033] (1) Ingredients

[0034] The mol ratio of nanometer carbon powder and titanium oxide is 2.5: 1;

[0035] (2) Mechanical activation

[0036] The raw materials are activated by high-energy mechanical ball milling, the weight ratio of balls to materials is 30:1, the medium is absolute ethanol, the speed of the ball mill is 700 rpm, and the ball milling time is 4 hours;

[0037] (3) dry

[0038] Dry the wet abrasive at 70°C for 24 hours;

[0039] (4) Loading

[0040] Weigh 10g of activation material and put it into the crucible of carbon tube furnace;

[0041] (5) Reactive heat treatment

[0042] Evacuate the carbon tube furnace to a vacuum of 2.0×10 -2 At MPa, start heating at 20°C / min, keep warm at 900°C for 5 minutes, and pass nitrogen gas at the end of the heat preservation until the pressure is 0.005MP...

Embodiment 2

[0046] In the present embodiment, raw material is nano-titanium oxide and nano-carbon powder, has the following process steps according to process flow chart 1:

[0047] (1) Ingredients

[0048] The mol ratio of nanometer carbon powder and titanium oxide is 2.7: 1;

[0049] (2) Mixing

[0050] Perform high-energy mechanical ball milling activation (dry milling) on the prepared raw materials, the ball-to-material weight ratio is 30:1, the ball mill speed is 700 rpm, and the ball milling time is 2 hours;

[0051] (3) Loading

[0052] Weigh 10g of activated raw material and put it into the crucible of the carbon tube furnace;

[0053] (4) Reactive heat treatment

[0054] Fill the carbon tube furnace with nitrogen to a pressure slightly greater than 1 standard atmosphere, then flow nitrogen and heat at 15°C / min at the same time, keep warm for 2 hours after reaching 1250°C;

[0055] (5) Sieve

[0056] The reaction heat treatment product is sieved to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com