Nitrogen-containing hard alloy based on multi-element composite titanium carbonitride solid solution and preparation method for nitrogen-containing hard alloy

A cemented carbide, multi-component composite technology, applied in the field of cemented carbide, can solve the problem of low strength and hardness of cemented carbide, achieve the effect of improving hardness and toughness, strengthening the bonding phase, and realizing the effect of hardness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

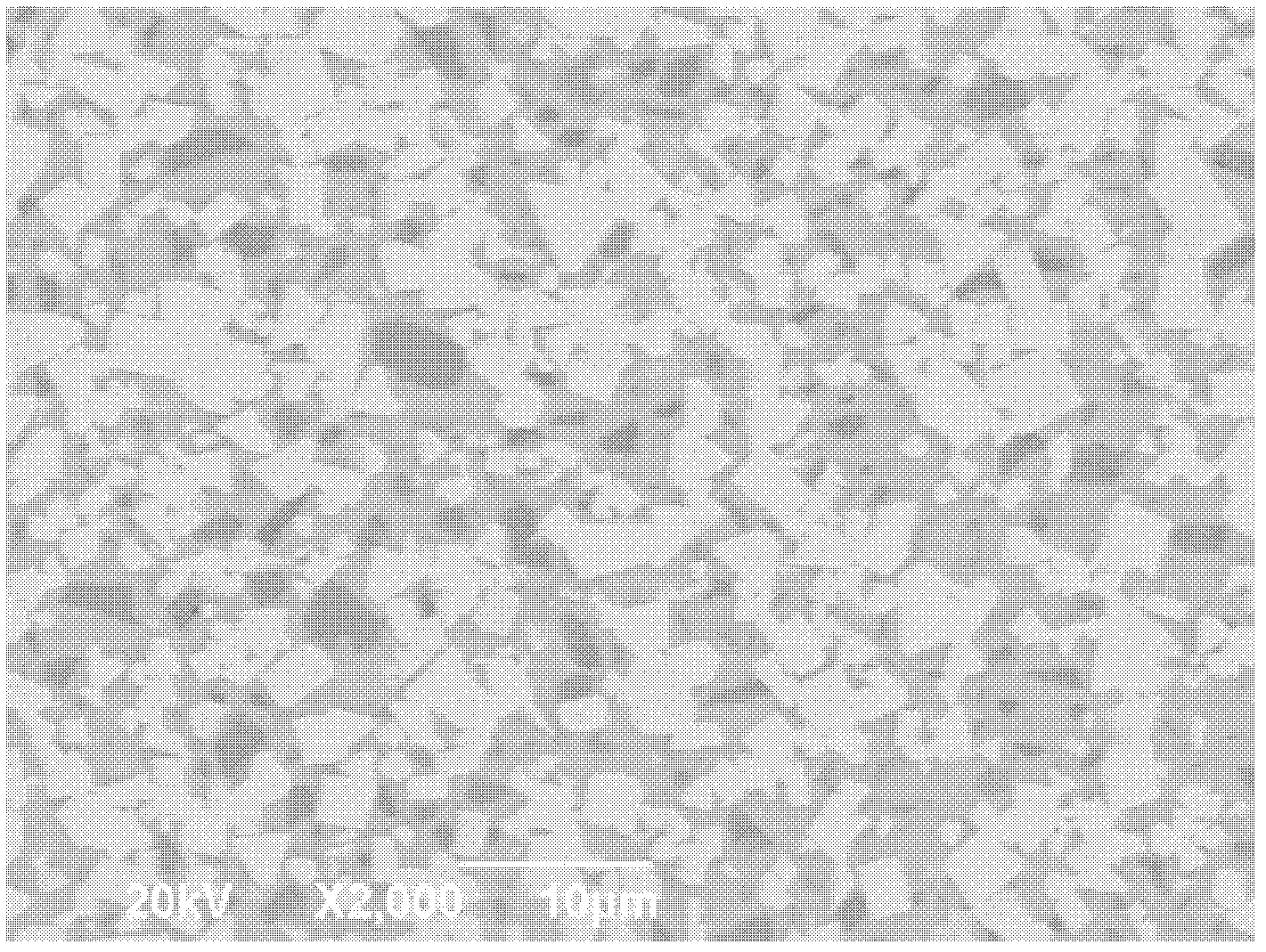

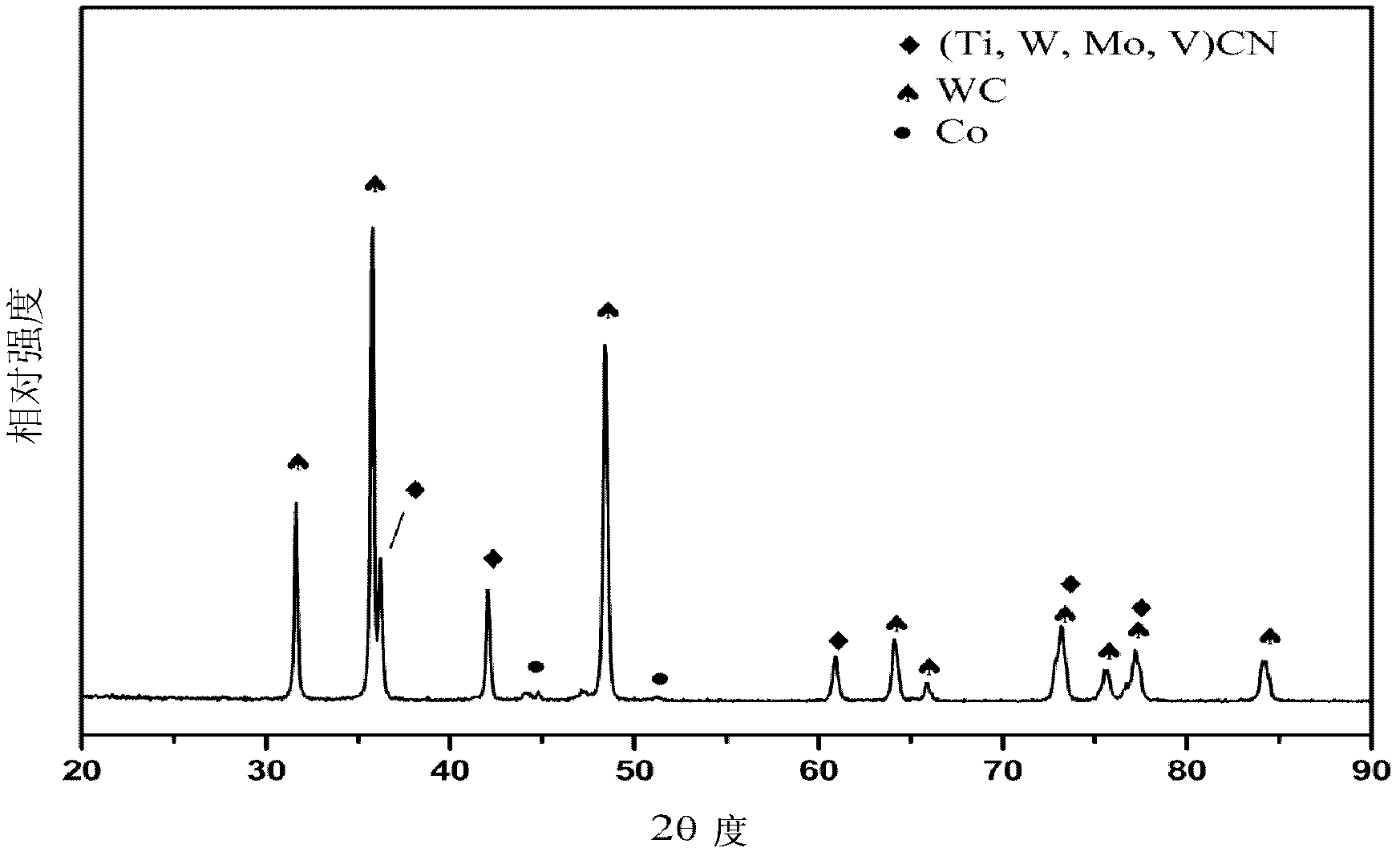

Image

Examples

Embodiment 1

[0030] The raw materials used in this embodiment and the processing steps are as follows:

[0031] Weigh 82g WC powder, 8g Co powder and 10g (Ti, 15W, 5Mo, 0.2V) (C 0.7 , N 0.3 ) solid solution powder, then put it into a ball mill tank, put into balls according to the ball-to-material ratio of 6:1, pour 100ml of alcohol, and ball mill for 72 hours to obtain a mixed wet material, which is dried in an oven at 70°C for 1.5 hour, according to 0.5% of the weight of the dried mixture, add molding agent paraffin and mix evenly, and then pass the 800-mesh sieve after drying the mixture added with paraffin in an oven at 70°C for 1 hour, and sieve the mixed powder Granulate through a granulator to form a granular mixture;

[0032] Weigh 10 parts of 8.4g granular mixture, put it into the cavity of the mold successively, press it into 10 cemented carbide product blanks, then put the cemented carbide blanks into a low-pressure sintering furnace for sintering, and the sintering The proce...

Embodiment 2

[0035] The raw materials used in this embodiment and the processing steps are as follows:

[0036] Weigh 74g of WC powder, 6g of Co powder and 20g of (Ti, 15W, 5Mo) (C0.5, N0.5) solid solution powder respectively, and then put them into a ball mill jar, put them into balls according to the ball-to-material ratio of 8:1, and ball mill Add 85ml of alcohol, ball mill for 24 hours to get the mixed wet material, dry the mixed wet material in an oven at 60°C for 2 hours, add molding agent rubber according to 1% of the weight of the dried mixture and mix evenly, then add the rubber The mixed material is dried in an oven at 80°C for 1 hour and passed through a 300-mesh sieve, and the sieved mixed powder is granulated by a granulator to form a granular mixed material;

[0037] Weigh 2 parts of 35.8g granular mixture, put it into the cavity of the mold successively, press it into 2 cemented carbide product blanks, then put the cemented carbide blanks into a low-pressure sintering furnac...

Embodiment 3

[0040] The raw materials used in this embodiment and the processing steps are as follows:

[0041] Weigh 60g WC powder, 10g Co powder and 30g (Ti, 5Nb, 5Mo, 0.2Cr, 0.5Y, 0.5Nd) (C 0.9 , N 0.1 ) solid solution powder, then put it into a ball mill tank, put into balls according to the ball-to-material ratio of 4:1, and pour 115ml of alcohol into it, and ball mill it for 36 hours to obtain a mixed wet material, and dry the mixed wet material in an oven at 80°C for 1 hour, according to 2wt% of the weight of the dried mixture, add forming agent polyethylene glycol and mix uniformly, then the mixture added with polyethylene glycol is passed through a 600-mesh sieve after being dried at 80°C for 1 hour in an oven, and the sieved The divided mixed powder is granulated by a granulator to form a granular mixture;

[0042] Weigh 2 parts of granular mixture of 49.5g, put it into the cavity of the mold successively, press it into 2 cemented carbide product blanks, then put the cemented c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com