Method of rapid manufacture of stamping die for arc spraying covering-piece for automobile

A technology of automobile cover parts and manufacturing methods, which is applied in the direction of manufacturing tools, forming tools, metal processing equipment, etc., can solve the problems affecting the precision of molds, complex processes, strength, poor surface wear resistance, etc., to ensure the overall performance requirements, reduce the The effect of cost and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiments given by the inventor according to the technical solution of the present invention.

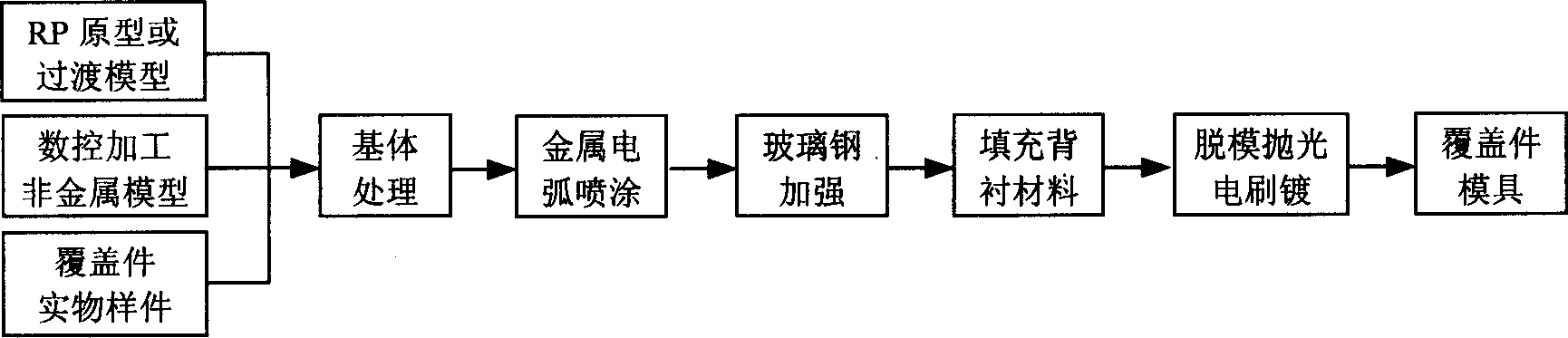

[0025] 1) The technical approach of mold manufacturing

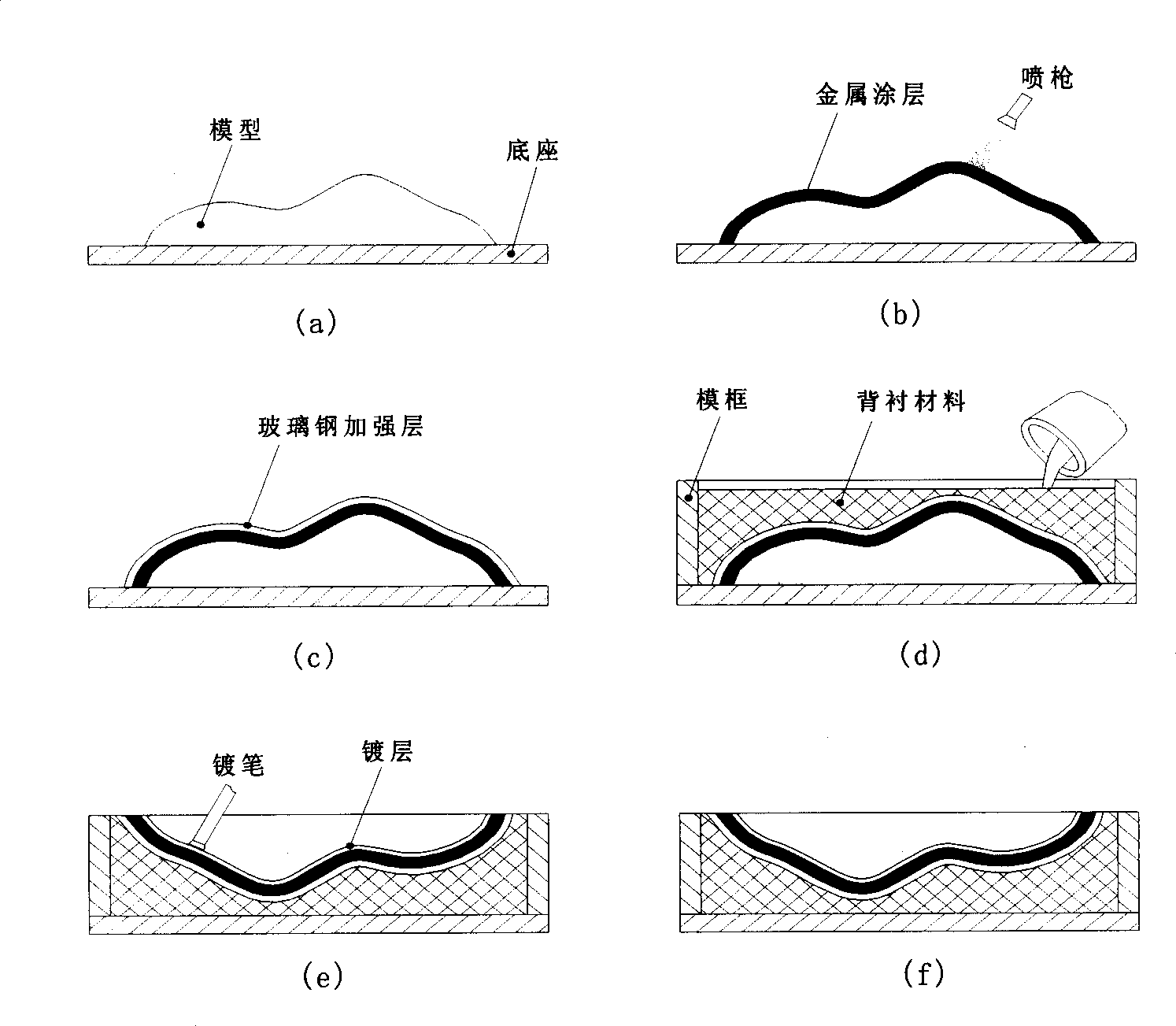

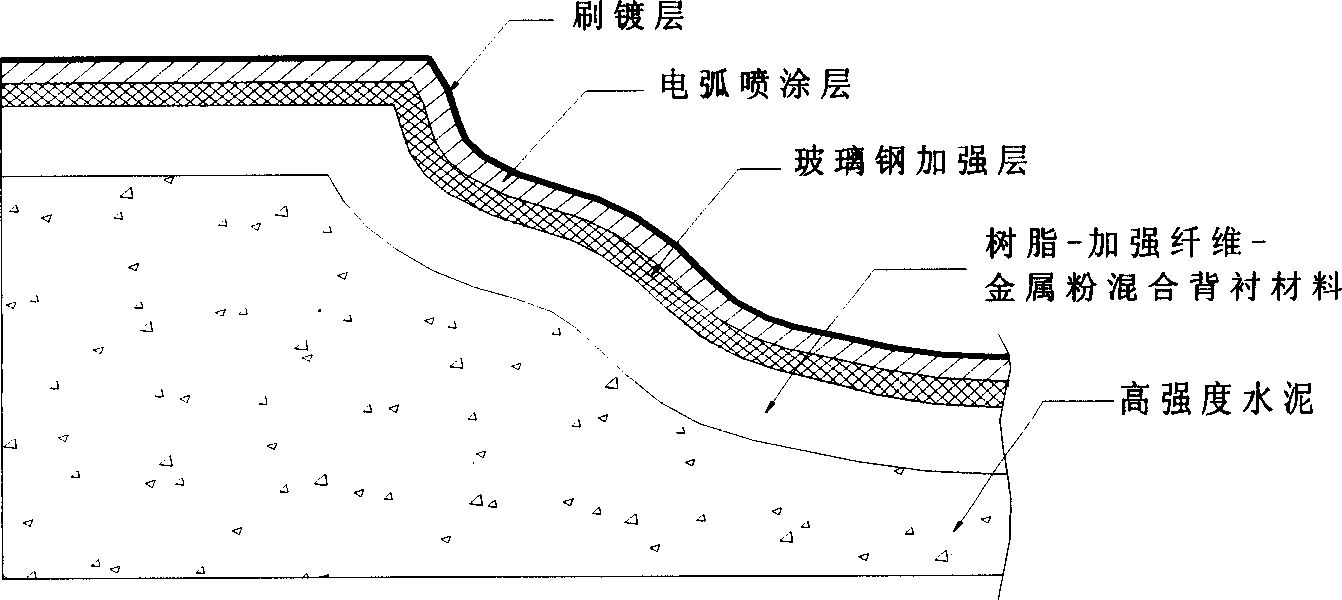

[0026] see figure 1 , the technical approach of utilizing the present invention to carry out rapid manufacturing of stamping dies is as follows: ① polishing the surface of the RP prototype or its transitional model or the non-metallic model or part sample obtained by numerical control processing, and then evenly coat a layer of Release agent; ②Carry out metal arc spraying on the above-mentioned model or sample after substrate treatment to form a metal thin shell with a certain thickness; Cavity bending and shearing resistance; ④ Pour epoxy resin-reinforcing fiber-metal powder mixture and other backing materials into the sprayed mold cavity and the prepared metal mold frame, and embed inserts as requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com