Gradient-structure hard alloy roll collar and manufacturing process thereof

A gradient structure, hard alloy technology, applied in the manufacture of tools, metal rolling, metal rolling, etc., can solve the problems of rapid expansion of roll rings, cracking, and easy microcracks on the surface of rolling grooves, etc., to reduce production costs , reduce roll breakage rate, good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

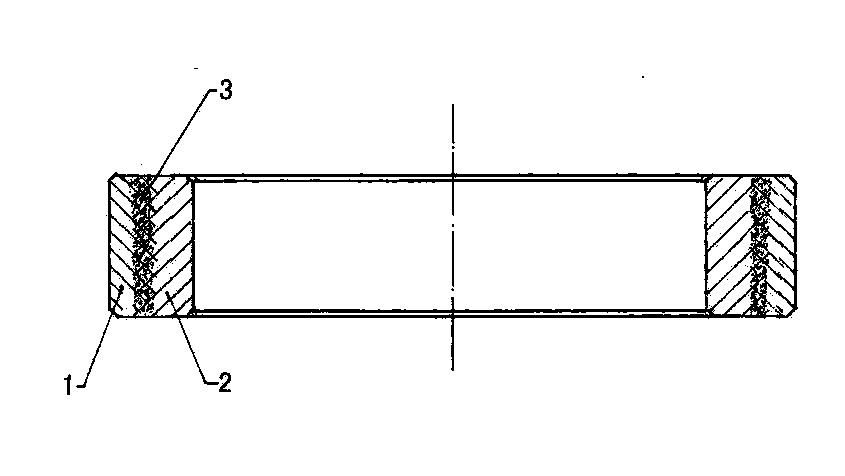

[0030] The gradient structure cemented carbide roll ring includes a roll ring outer layer 1 and a roll ring core 2, the roll ring outer layer 1 is arranged on the outer surface of the roll ring core 2, and the roll ring outer layer 1 is on There is a mutual melting layer 3 between the ring cores 2 .

[0031] 1. Regarding the material selection of the outer layer 1 of the roller ring and the core part 2 of the roller ring:

[0032] The outer layer 1 of the roll ring is made of hard materials, binders and additives, while the core 2 of the roll ring is made of hard materials and binders, and a composition gradient is formed between the outer layer 1 of the roll ring and the core 2 of the roll ring. , that is, the same material with different particle sizes is used, and different materials with different particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com