Galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance and water-based surface treating agent

A surface treatment agent, wear resistance technology, applied in the direction of coatings, polyurea/polyurethane coatings, anti-corrosion coatings, etc., can solve the problems of increasing the mechanical strength and wear resistance of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

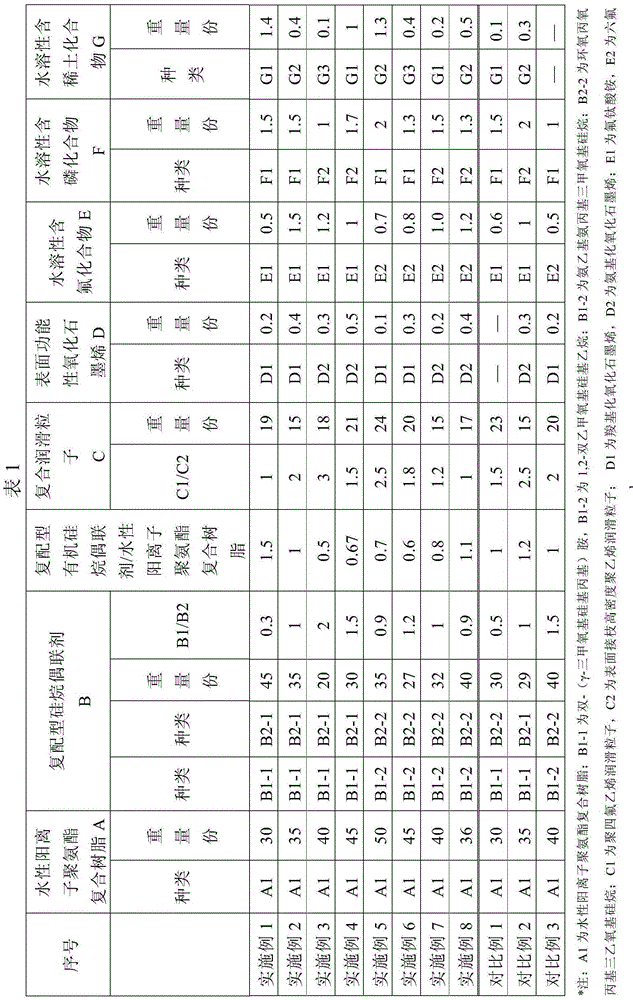

Embodiment 1-8 and comparative example 1-3

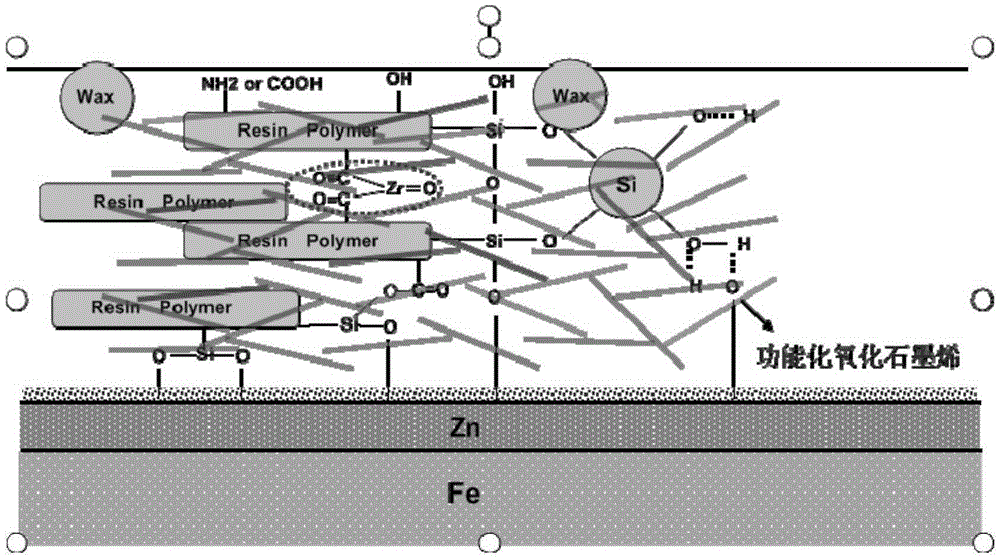

[0087] The substrates of Examples 1-8 and Comparative Examples 1-3 all adopt 0.5mm galvanized steel sheets, and the zinc layer weight is 60 / 60g / m 2 , first spray and clean the surface of the steel plate with a medium-alkalinity degreasing agent (pH: 9-10), then wash it with pure water to remove the residual alkaline components on the surface, and apply an environmentally friendly surface treatment agent for galvanized steel plates Drying is carried out at 80-180°C on the surface of the galvanized steel sheet to form a composite film with a thickness of 2-4 microns on the surface of the galvanized steel sheet.

[0088] Table 1 lists the parts by weight of each component in the environmental-friendly surface treatment agent for galvanized steel sheets in Examples 1-8 and Comparative Examples 1-3.

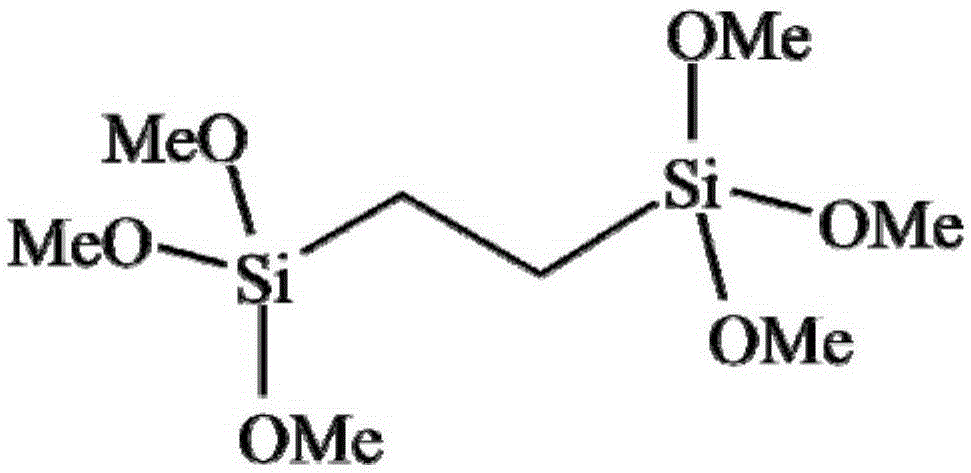

[0089] figure 1 It is a schematic diagram of the structure of bisorganosiloxane (1,2-bisethylmethoxysilylethane). It can be seen that there are 6 alkoxy groups available for reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com