Multi-degree of freedom electromagnetic damper

A technology of electromagnetic dampers and degrees of freedom, applied in the directions of magnetic springs, springs/shock absorbers, springs, etc., can solve the problems of large fluctuation of damping force and asymmetric distribution of damping force, and achieve large damping force, small deformation and distribution. symmetrical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

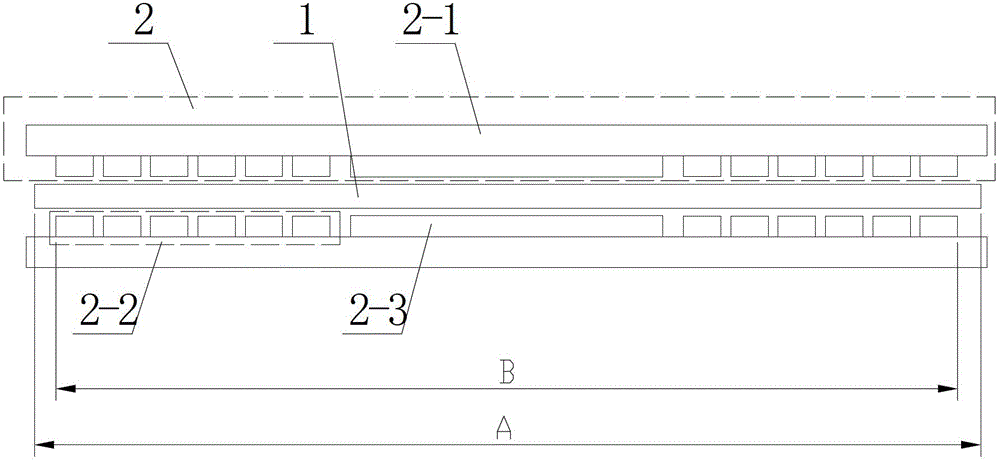

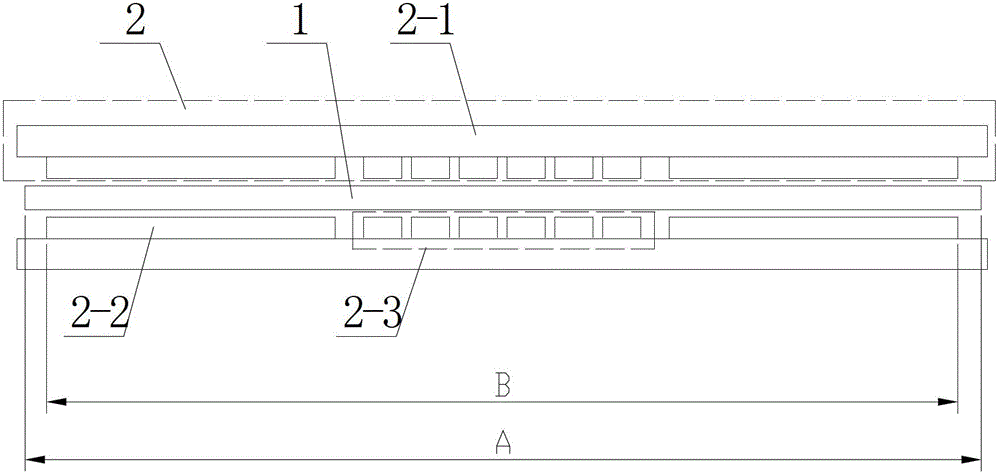

[0039] Specific implementation mode one: the following combination Figure 1 to Figure 4Describe this embodiment, the multi-degree-of-freedom electromagnetic damper in this embodiment includes a primary 1 and two secondary 2, the primary 1 is a low-resistivity non-magnetic metal plate, and the two secondary 2 are symmetrically distributed On both sides of primary 1, an air gap is formed between each secondary 2 and primary 1,

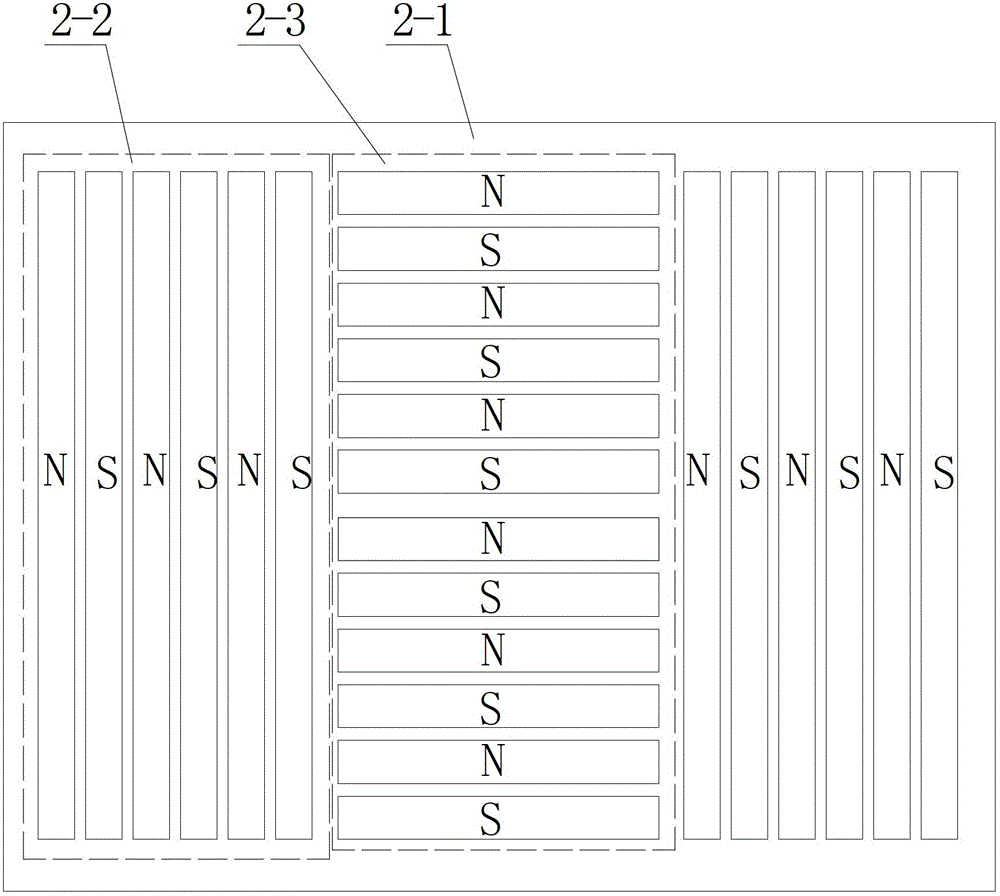

[0040] Each secondary 2 includes a secondary yoke plate 2-1, n+1 groups of X-direction excitation units 2-2 and n groups of Y-direction excitation units 2-3, where n is a positive integer,

[0041] n+1 groups of X-direction excitation units 2-2 and n groups of Y-direction excitation units 2-3 are arranged on the secondary yoke plate 2-1 at equal intervals in turn, and each group of X-direction excitation units 2-2 consists of multiple pieces Composed of elongated permanent magnets, the multiple elongated permanent magnets are evenly arranged in the sam...

specific Embodiment approach 2

[0045] Specific implementation mode two: the following combination Figure 1 to Figure 4 This embodiment is described. This embodiment is a further description of Embodiment 1. The plurality of elongated permanent magnets of the X-direction excitation unit 2-2 are arranged along the length direction or width direction of the secondary yoke plate 2-1.

specific Embodiment approach 3

[0046] Specific implementation mode three: the following combination Figure 5 Describe this embodiment, this embodiment is a further description of Embodiment 1 or 2, the plurality of elongated permanent magnets of the X-direction excitation unit 2-2 are arranged along the length direction of the secondary yoke plate 2-1, the Each elongated permanent magnet is composed of three longitudinal segments of permanent magnets along its length direction, and the intervals between the three segments of permanent magnets are equal; The level yoke plates 2-1 are arranged in the width direction, and each elongated permanent magnet is composed of two transverse segments of permanent magnets along its length direction, and there is a distance between the two transverse segments of permanent magnets.

[0047] In this embodiment, Figure 5 As shown, there are 2 sets of X-direction excitation units 2-2 and 1 group of Y-direction excitation units 2-3. The elongated permanent magnet is divid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com