Mould for extruding aluminum alloy

An aluminum alloy and mold technology, which is applied in the field of high-strength aluminum alloy extrusion dies, can solve the problems of high-strength hard aluminum alloy super-large section forming, microstructure and insufficient extrusion force, etc., to achieve good forming, reduce extrusion force, and improve organization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

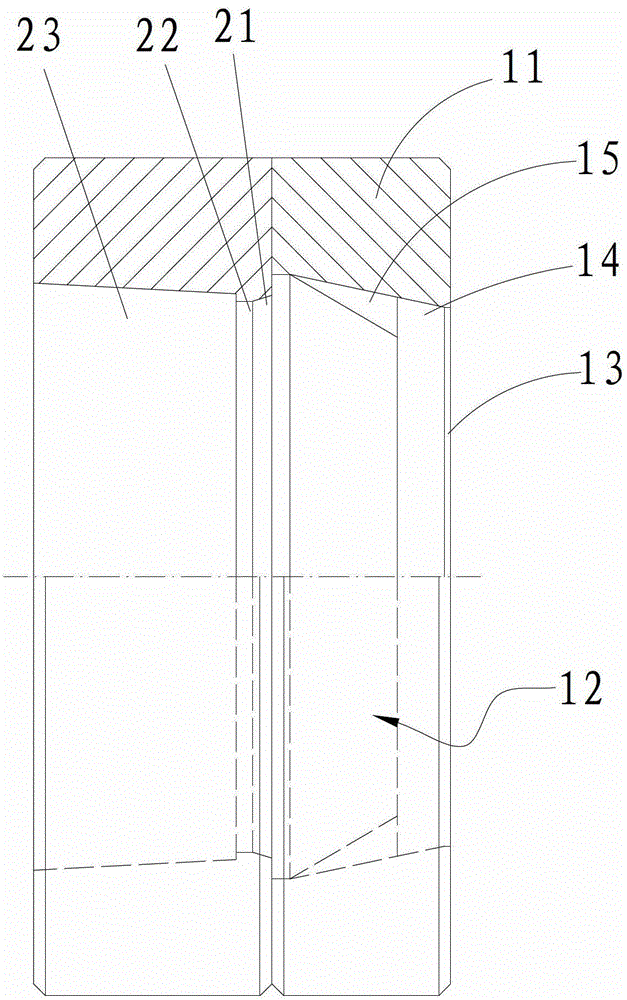

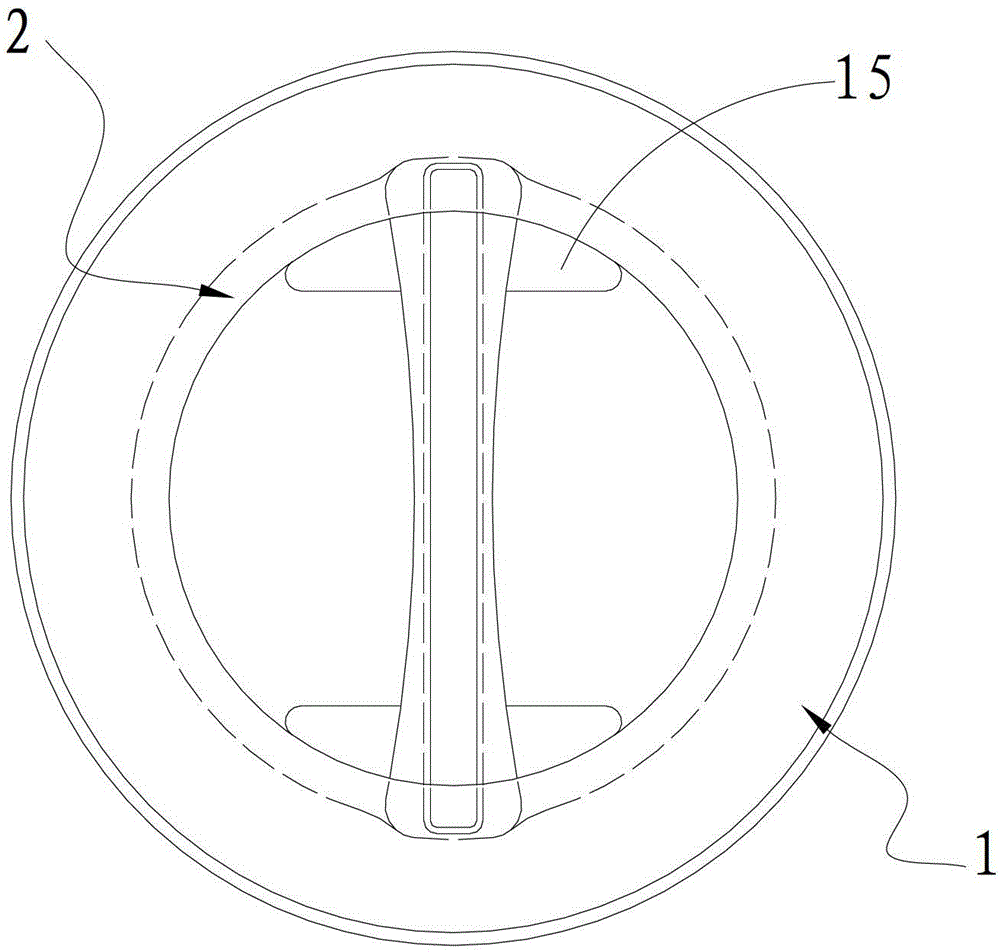

[0017] Please also refer to figure 1 with figure 2 , as shown in the figure, the peeling and pressure-reducing extrusion die of the present invention "first countersunk, widen and then reverse cone" includes a diversion die 1 and a mold 2 arranged front and back along the fluid direction, and the diversion die 1 and the die 2. Design the corresponding cavity size according to the parts. The diversion mold 1 is composed of a sinking platform 11 and a transition cavity 12. The sinking platform 11 is an inner tapered structure, and the front end of the transition cavity 12 is a sinking hole structure. 13. The diameter of the counterbore structure 13 is smaller than the diameter of the outer circle, and the rear end of the counterbore struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com