Probe head adapter for checking probe

A technology for detecting probes and probe heads, which is applied in the direction of measuring leads/probes, parts of electrical measuring instruments, instruments, etc., and can solve problems such as limiting the input bandwidth of probes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

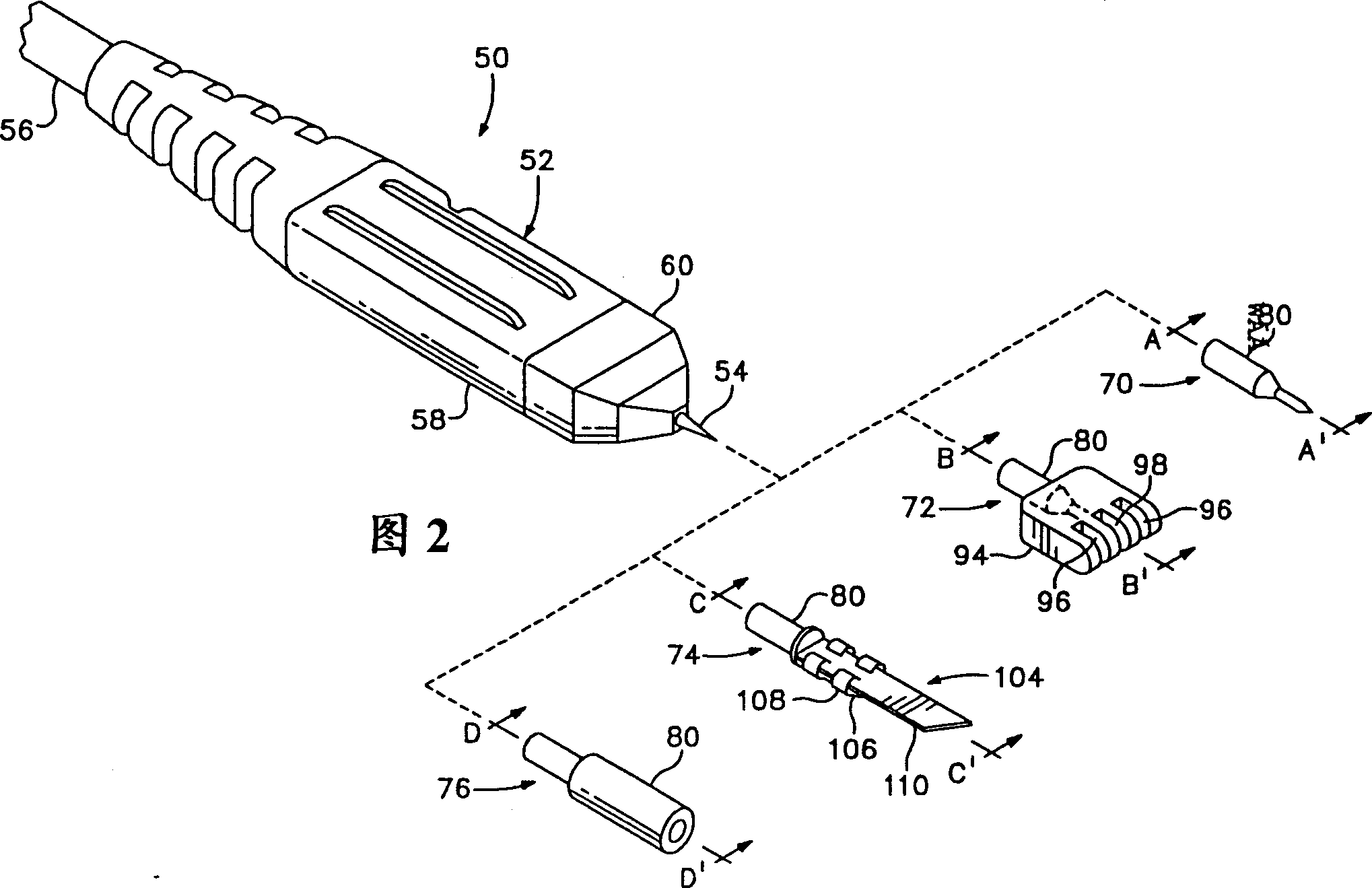

[0015] Referring to FIG. 2, this figure is a perspective view of a wideband high frequency test probe 50 for probing high bandwidth circuits. The detection probe 50 includes a probe head 52 with a probe head 54 protruding from one end of the probe. A coaxial cable 56 protruding from the other end connects the probe head 52 to a measuring instrument, such as an oscilloscope, a spectrum analyzer, a logic analyzer, and the like. The probe head 52 is provided with a conductive tubular housing 58 enclosing a substrate on which active and passive components are mounted to form the probe output circuit. Probe tip 54 and coaxial cable 56 are electrically connected to the substrate. Insulation material surrounds housing 58 and a portion of coaxial cable 56 .

[0016] To achieve wide bandwidths and multi-gigahertz frequencies, tip capacitance and inductance need to be kept to a minimum. To achieve this, the length and diameter of the probe tip 54 are reduced to the extent possible. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com