Elastic core bar for bent pipe

An elastic core and pipe bending technology, which is applied in the field of elastic mandrels for pipe bending, can solve problems such as easy breakage, and achieve the effect of improving molding quality and effective and reasonable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

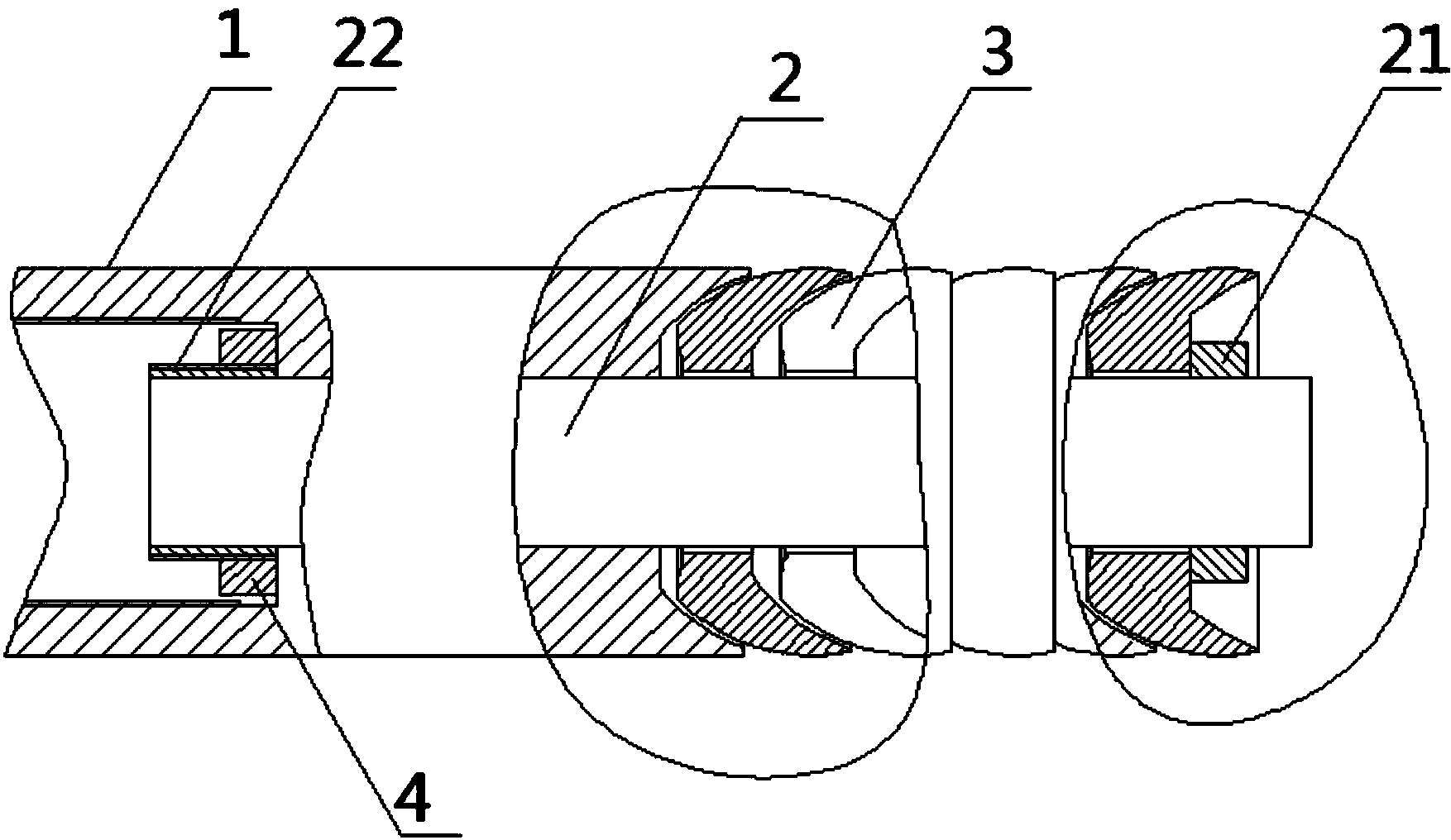

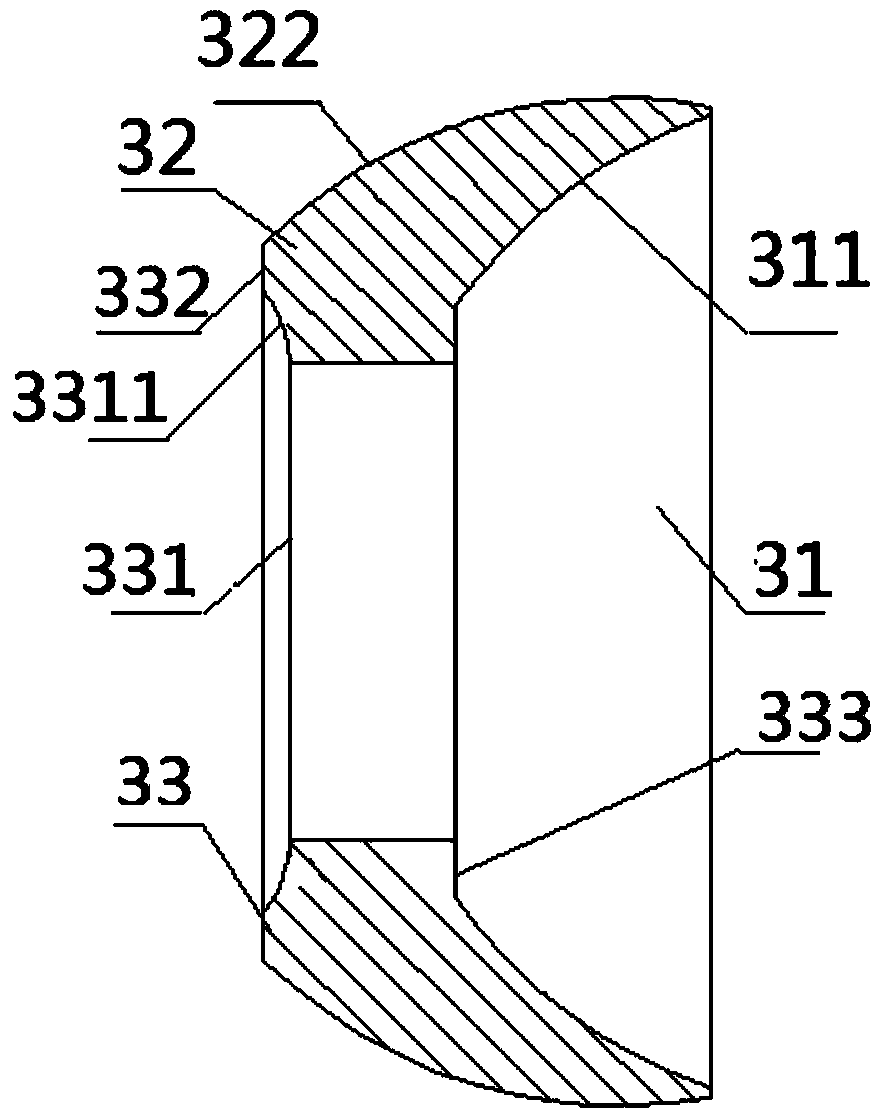

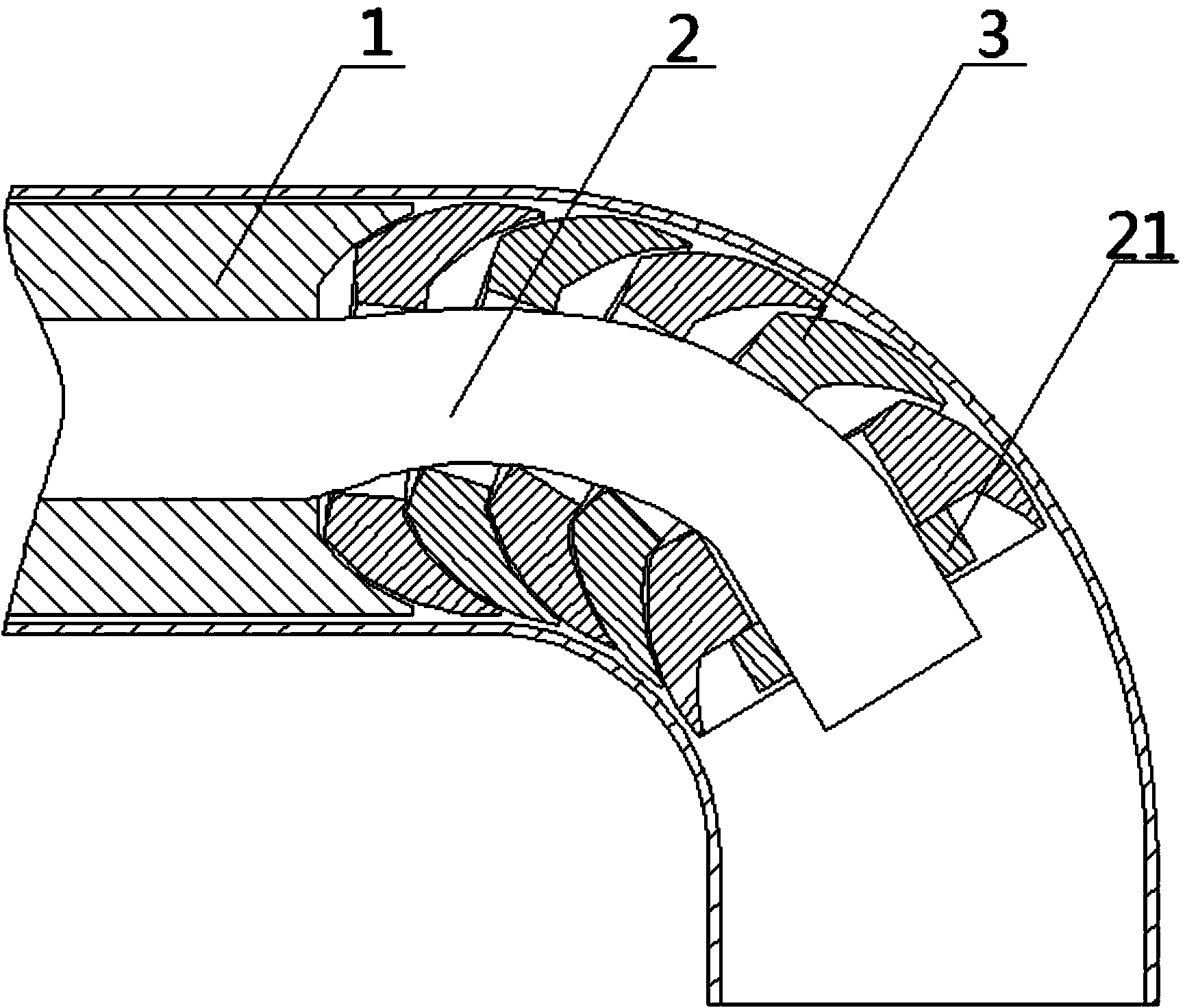

[0028] Refer to attached Figure 1-6 , an elastic mandrel for a bent pipe, comprising a mandrel 1 for supporting a straight pipe section and several core balls 3 for supporting a bent pipe section, the mandrel 1 and the core balls 3 are connected by an elastic body 2, The fixed end of the elastic body 2 is fixed in the mandrel 1, the free end of the elastic body 2 passes through the core ball 3 in turn and is provided with a clamping positioning block 21 for limiting the displacement of the core ball 3 at the end; defining the core The distance between the two end faces of the ball 3 is the thickness of the core ball 3, and the thickness of the core ball 3 is inconsistent.

[0029] Preferably, the front end is close to the mandrel 1 and the end is far away from the mandrel 1 , the thickness of the core ball 3 at the front end is shorter than the thickness of the core ball 3 at the end.

[0030] Preferably, the front end is close to the mandrel 1 and the end is far away from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com