Cold tandem mill strip steel edge trimming controlling method

A technology of a cold tandem rolling mill and a control method, which is applied to the rolling mill control device, metal rolling, metal rolling and other directions, can solve the problems of high cost and complicated process realization, and achieve the effect of eliminating the broken strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

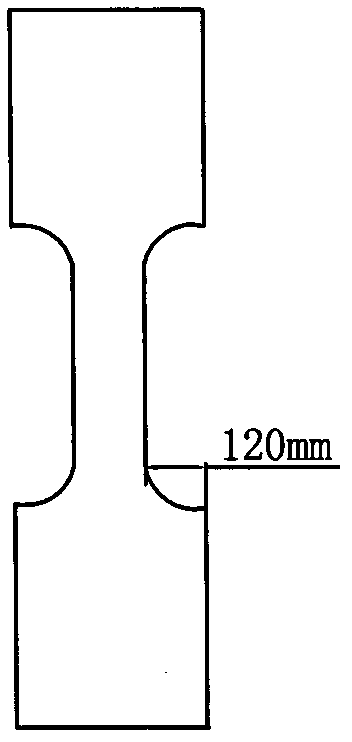

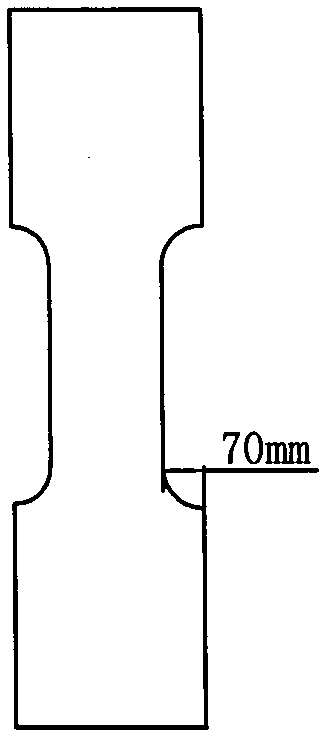

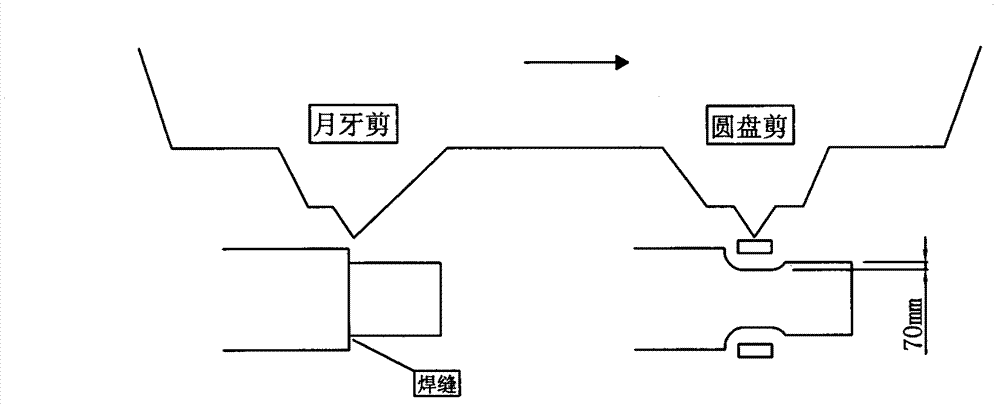

[0021] The strip edge trimming control method of the cold tandem rolling mill of this specific embodiment is, on the existing tandem cold rolling mill production line, utilize existing L1 basic control system and L2 process control system; figure 1 and figure 2 As shown, one is a small crescent punch with a punching depth of 70mm, and the other is a large crescent punch with a punching depth of 120mm; the crescent scissors and disc scissors are controlled as follows:

[0022] 1) if image 3 As shown, when the strip width difference before and after the welding seam is 0-75mm, control the crescent shears to perform small crescent edge punching at the weld seam, and control the disc shears to perform edge trimming at the weld seam;

[0023] 2) When the strip width difference before and after the weld is greater than 75mm,

[0024] like Figure 4 As shown, if the front and rear strips are narrow at the front and wide at the rear, control the crescent shears to perform small c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com