Method for improving strength of pole piece of square lithium ion battery after Mark hole drilling

A lithium-ion battery, square technology, used in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve the problems of broken tape, troublesome splicing, affecting production efficiency, etc., to avoid damage, reduce concentration, and prevent breakage. band effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment one: a method for improving the strength of the pole piece after punching a Mark hole in a square lithium-ion battery, comprising the following steps:

[0038] S1. Pre-optimize the raw materials, remove the surface burrs, protrusions or other impurities that affect the Mark hole processing, then place them on the processing machine and fix them, and prepare for processing;

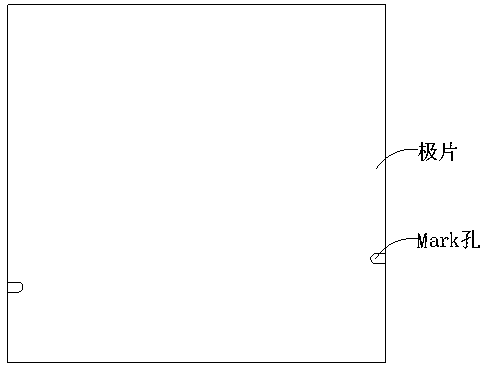

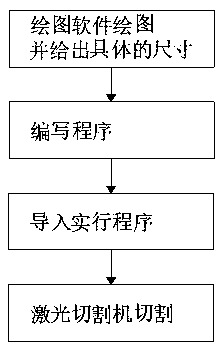

[0039] S2. Draw the cutting diagram of the lithium-ion battery for punching Mark holes on both sides, and the round groove of the Mark hole is set on the edge of the tab. (When drawing the punching diagram of the Mark hole, the diagram is drawn by laser drawn by software);

[0040] S3. Optimize the size of the original mark hole to 3mm*5mm on the basis of the conventional size of 5mm*8mm (the lower limit of specific optimization may vary, depending on the ability of the winding machine to recognize the size of the mark hole, the smaller the size, the more The higher the tensile strength ...

Embodiment 2

[0048] Embodiment two: a method for improving the strength of the pole piece after punching a Mark hole in a square lithium-ion battery, comprising the following steps:

[0049] S1. Pre-optimize the raw materials, remove the surface burrs, protrusions or other impurities that affect the Mark hole processing, then place them on the processing machine and fix them, and prepare for processing;

[0050] S2. Draw the cutting diagram of the lithium-ion battery for punching Mark holes on both sides, and the round groove of the Mark hole is set on the edge of the tab. (When drawing the punching diagram of the Mark hole, the diagram is drawn by laser drawn by software);

[0051] S3. Optimize the size of the original mark hole to 3mm*5mm on the basis of the conventional size of 5mm*8mm (the lower limit of specific optimization may vary, depending on the ability of the winding machine to recognize the size of the mark hole, the smaller the size, the more The higher the tensile strength ...

Embodiment 3

[0059] Embodiment three: a method for improving the strength of the pole piece after punching a Mark hole in a square lithium-ion battery, comprising the following steps:

[0060] S1. Pre-optimize the raw materials, remove the surface burrs, protrusions or other impurities that affect the Mark hole processing, then place them on the processing machine and fix them, and prepare for processing;

[0061] S2. Draw the cutting diagram of the lithium-ion battery for punching Mark holes on both sides, and the round groove of the Mark hole is set on the edge of the tab. (When drawing the punching diagram of the Mark hole, the diagram is drawn by laser drawn by software);

[0062] S3. Optimize the size of the original mark hole to 3mm*5mm on the basis of the conventional size of 5mm*8mm (the lower limit of specific optimization may vary, depending on the ability of the winding machine to recognize the size of the mark hole, the smaller the size, the more The higher the tensile strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com