A control system for rolling plate thickness

A control system and rolling mill control technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of broken strips, flying plates, and increase production costs of enterprises, so as to avoid strip breaks and save production. Cost, convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

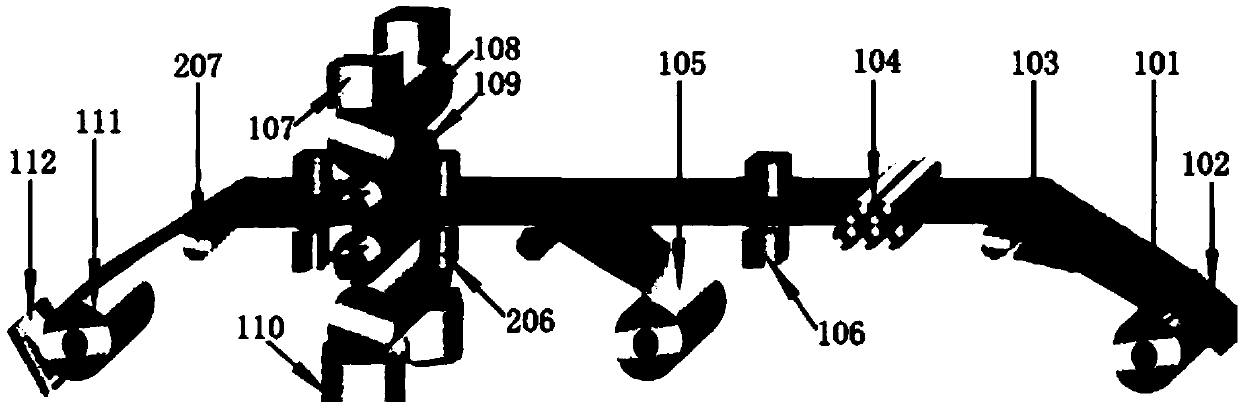

[0015] Such as figure 1 As shown, the rolling mill includes an uncoiler 101 and its pressure roller 102, telescopic guide plate 103, leveler 104, entrance tension roller 105, CPC 106, wedge 107, two back rollers 108, two worker rollers 109, two Push up the hydraulic cylinder 110, the exit tension roller 111 and its pressure roller 112. From the same direction gradually away from the unwinding machine 101, telescopic guide plate 103, leveler 104, CPC106, two work rolls 109, outlet tension roll 111 and pressure roll 112 thereof are arranged successively, and entrance tension roll 105 is located at work roll 109 and Between unwinding machines 101. Two working rollers 109 are arranged parallel to each other, and there is a working gap between them. A backing roller 108 is respectively arranged on the outside of the two working rollers 109. Wedges 107 are arranged on the backing roller 108 positioned at the top, and two Push up the hydraulic cylinder 110. The uncoiler 101 set is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com