Heat-treated steel sheet member, and production method therefor

一种制造方法、钢板的技术,应用在热处理炉、热处理设备、制造工具等方向,能够解决高加工部位断裂、压制成形性降低、不容易高强度压制成形等问题,达到拉伸强度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

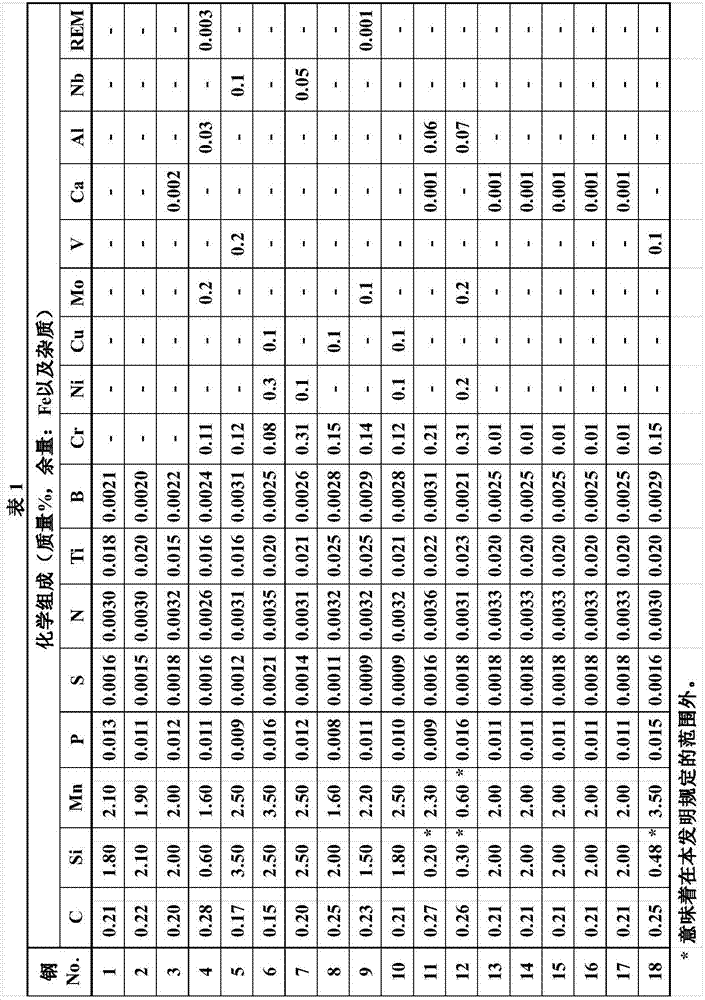

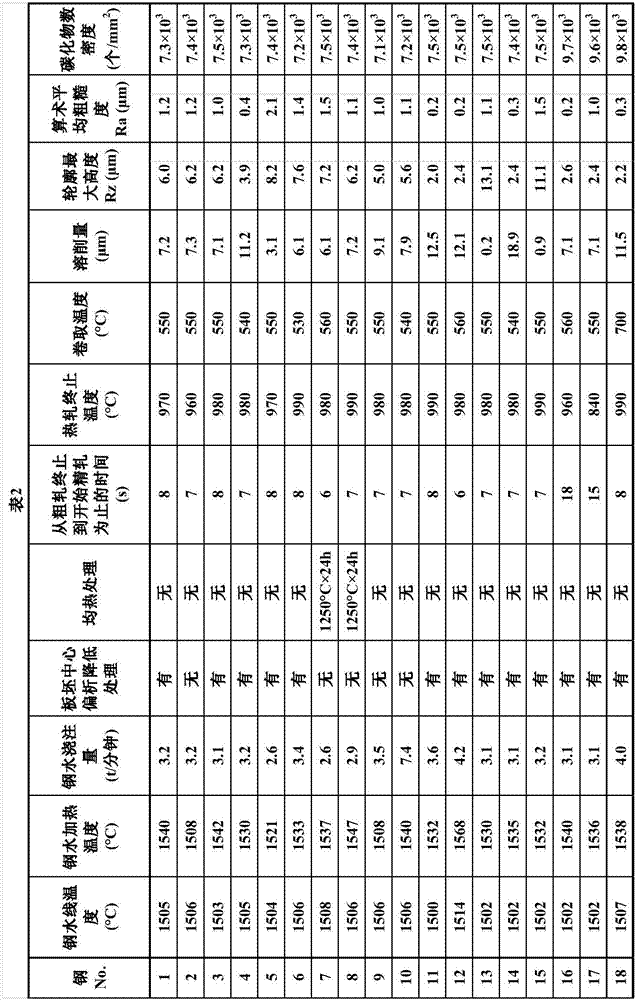

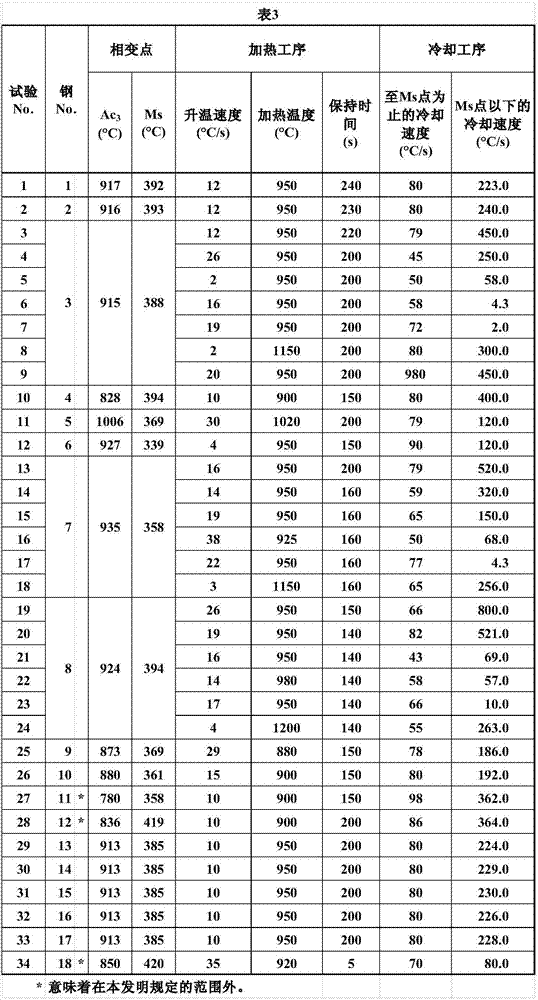

[0215] Steels having the chemical compositions shown in Table 1 were smelted in a test converter, and continuously cast by a continuous casting test machine to produce slabs with a width of 1000 mm and a thickness of 250 mm. At this time, the heating temperature of molten steel and the pouring amount of molten steel per unit time were adjusted according to the conditions shown in Table 2.

[0216] [Table 1]

[0217]

[0218] The cooling rate of the slab is controlled by changing the amount of water in the secondary cooling spray zone. In addition, the central segregation reduction treatment was carried out by performing light reduction at a gradient of 1 mm / m using rolls at the end of solidification, and discharging the enriched molten steel in the final solidification part. A part of the slabs were then soaked at 1250° C. for 24 hours.

[0219] The obtained slab was hot-rolled using a hot-rolling testing machine to form a hot-rolled steel sheet having a thickness of 3.0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com