Soft film pressure sensor

A film pressure and sensor technology, applied in the field of soft film pressure sensor, can solve the problems of test repeatability difference, hysteresis effect, etc., achieve the effect of light, thin and small size, change hysteresis effect, and improve sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

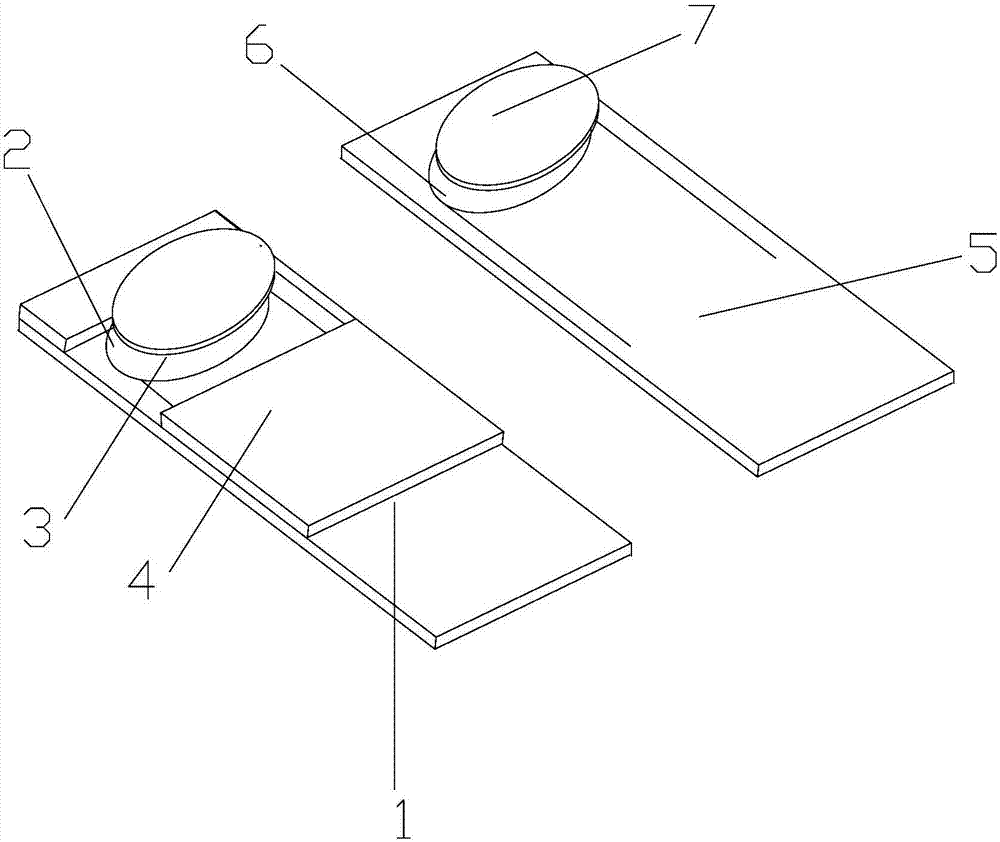

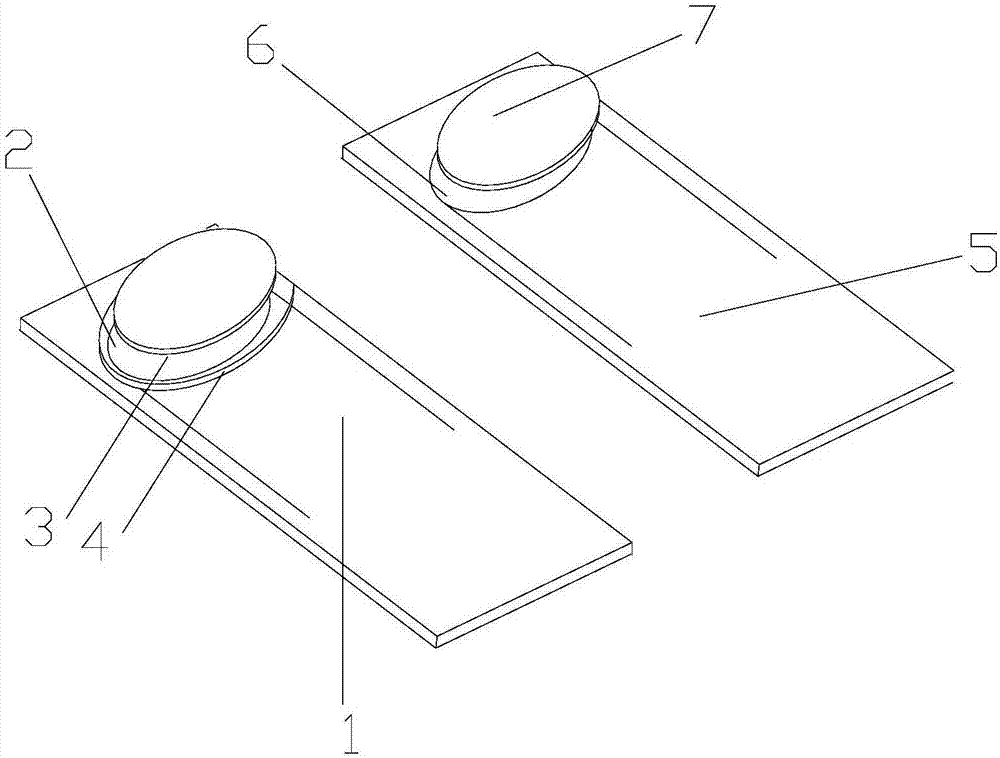

[0035] Implementation mode two: if figure 2As shown, it includes a first flexible substrate, a first electrode layer, a first pressure-sensitive layer, a supporting layer, a second flexible substrate, and a second electrode layer. The first electrode layer is located on the surface of the first flexible substrate and is in close contact with the substrate, the first pressure-sensitive layer covers the surface of the first electrode layer and is in close contact with the electrode layer; the support layer is located on the surface of the first pressure-sensitive layer or the support layer Located on the surface of the flexible substrate and surrounding the first pressure-sensitive layer or the supporting layer is located on the surface of the flexible substrate and on the side of the first pressure-sensitive layer; the second electrode layer is located on the surface of the second flexible substrate and connected to the substrate Close contact.

Embodiment approach 3

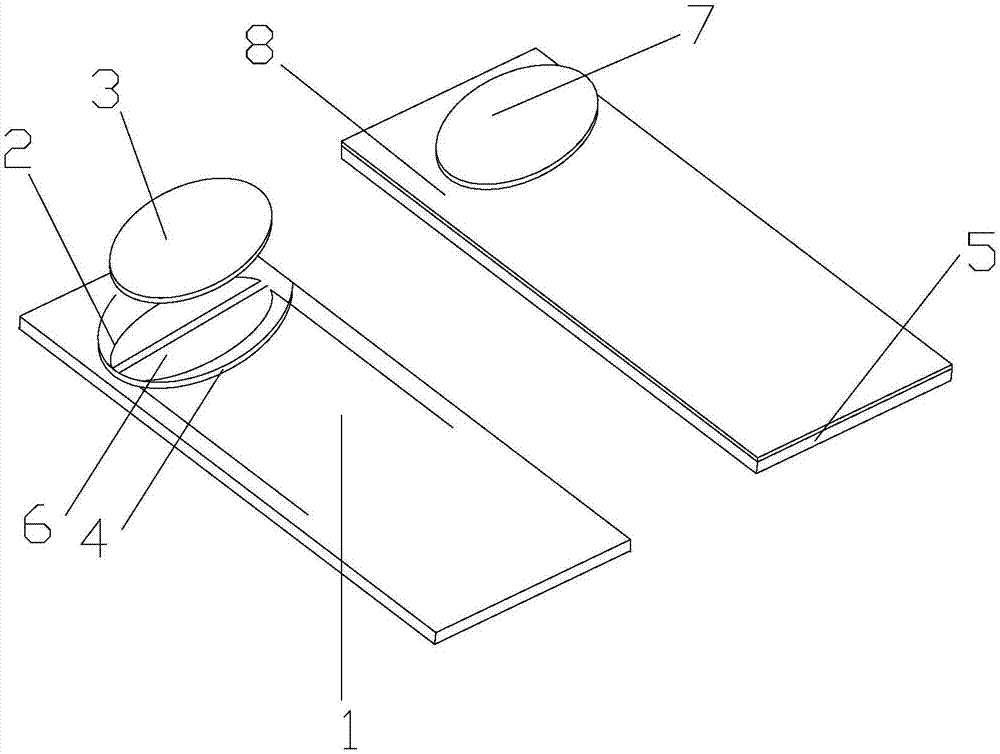

[0036] Implementation mode three: if image 3 As shown, it mainly includes a first flexible substrate, a first electrode layer, a second flexible substrate, a second conductive layer, a second pressure-sensitive layer, and a supporting layer. The first electrode layer is located on the surface of the first flexible substrate and is in close contact with the substrate, the second conductive layer is located on the surface of the second flexible substrate and is in close contact with the substrate, and the second pressure-sensitive layer covers the surface of the second conductive layer and in close contact with the conductive layer; the supporting layer is located on the surface of the second pressure-sensitive layer or the supporting layer is located on the surface of the second flexible substrate and surrounds the second pressure-sensitive layer or the supporting layer is located on the surface of the second flexible substrate and on the second flexible substrate Two sides of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com