Optical disk drive

A technology of optical disc drive and optical disc, which is applied in the directions of instruments, recording information storage, etc., can solve the problems that the optical disc drive is difficult to adopt, the optical disc drive becomes larger, and the moving time of the tray 30 becomes longer, so as to reduce the loading and non-loading time and improve the operation Quickly and minimize the effect of the length in the front-back direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

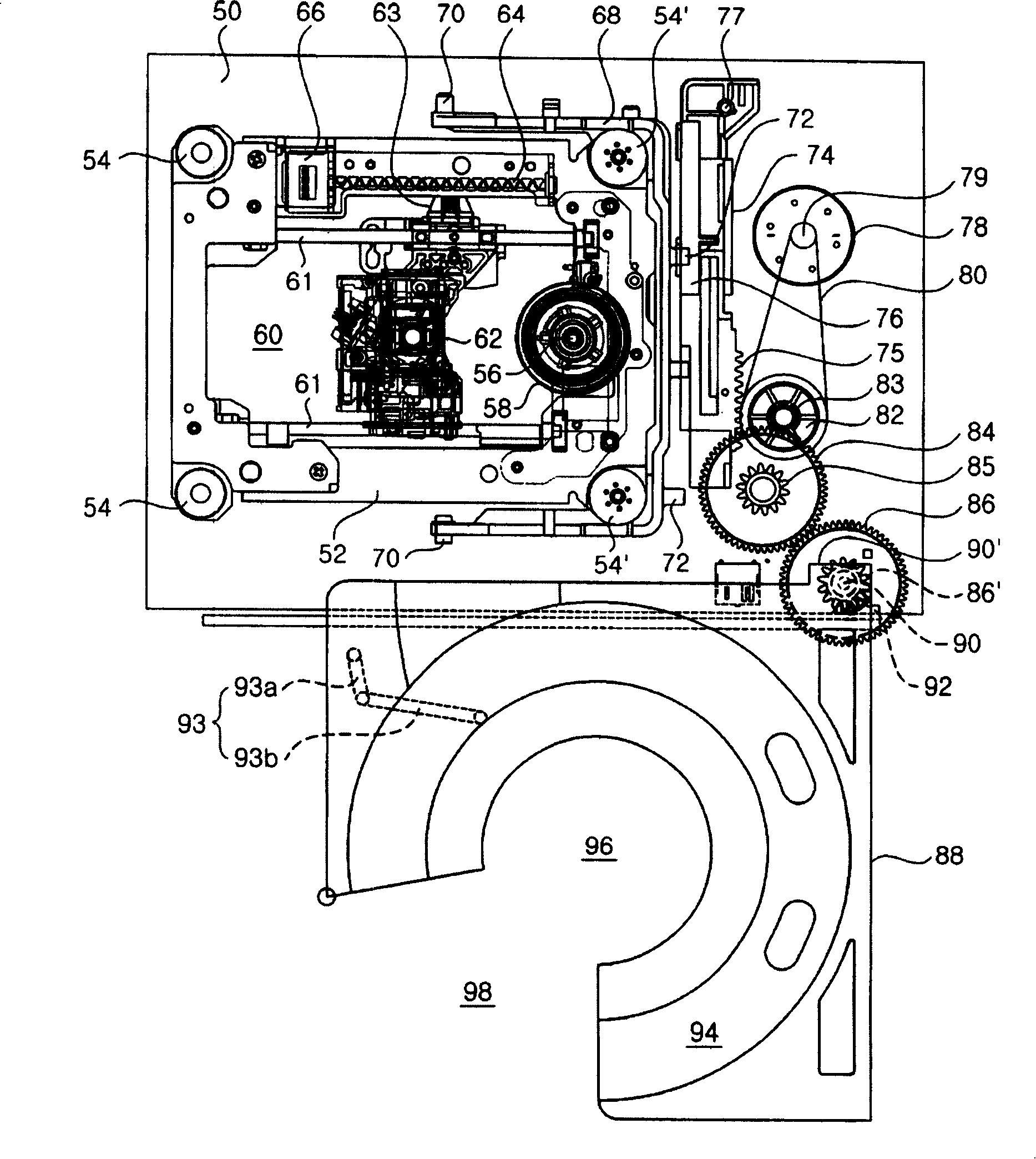

[0060] Hereinafter, specific embodiments of the optical disk drive of the present invention will be described in detail with reference to the accompanying drawings.

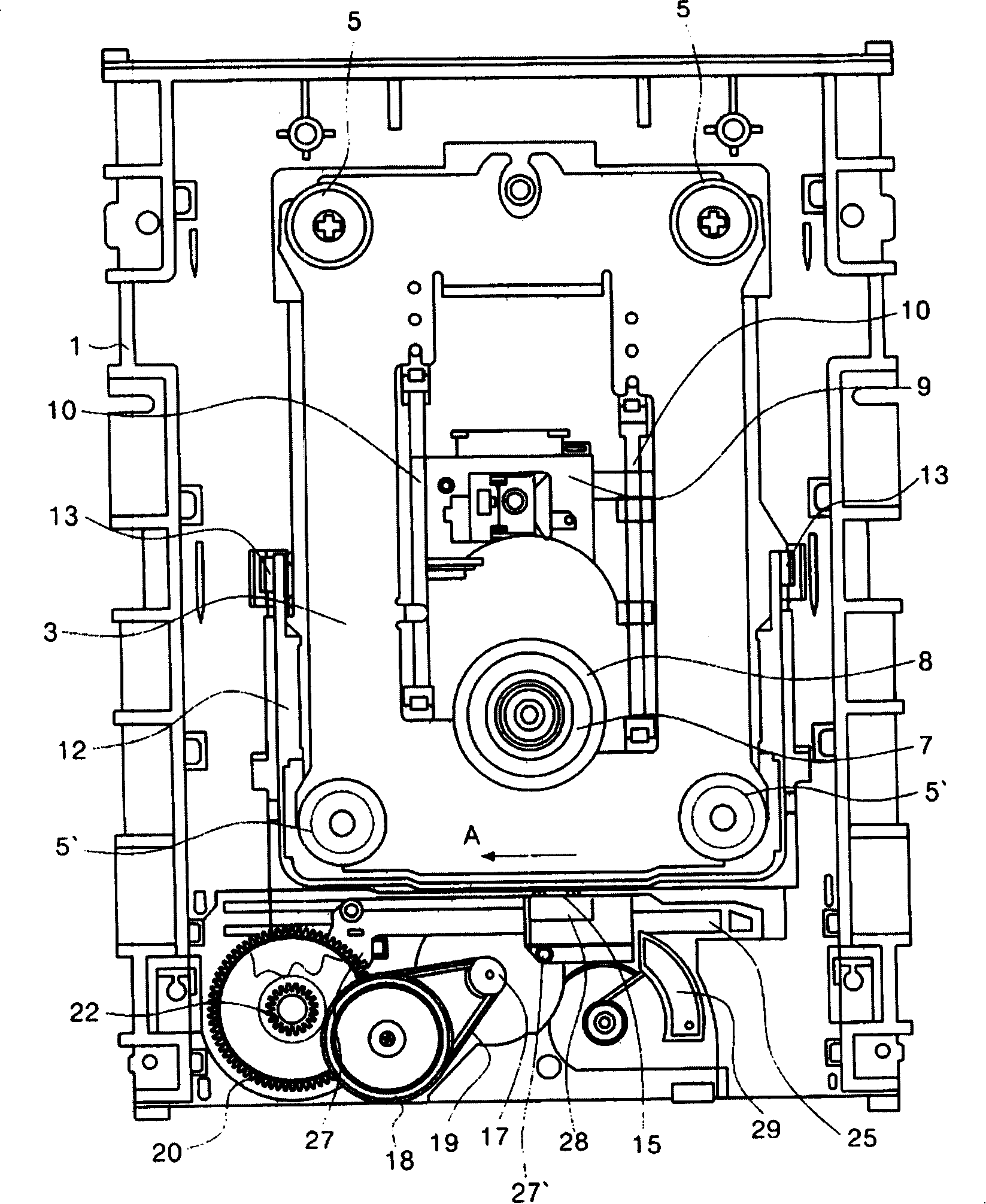

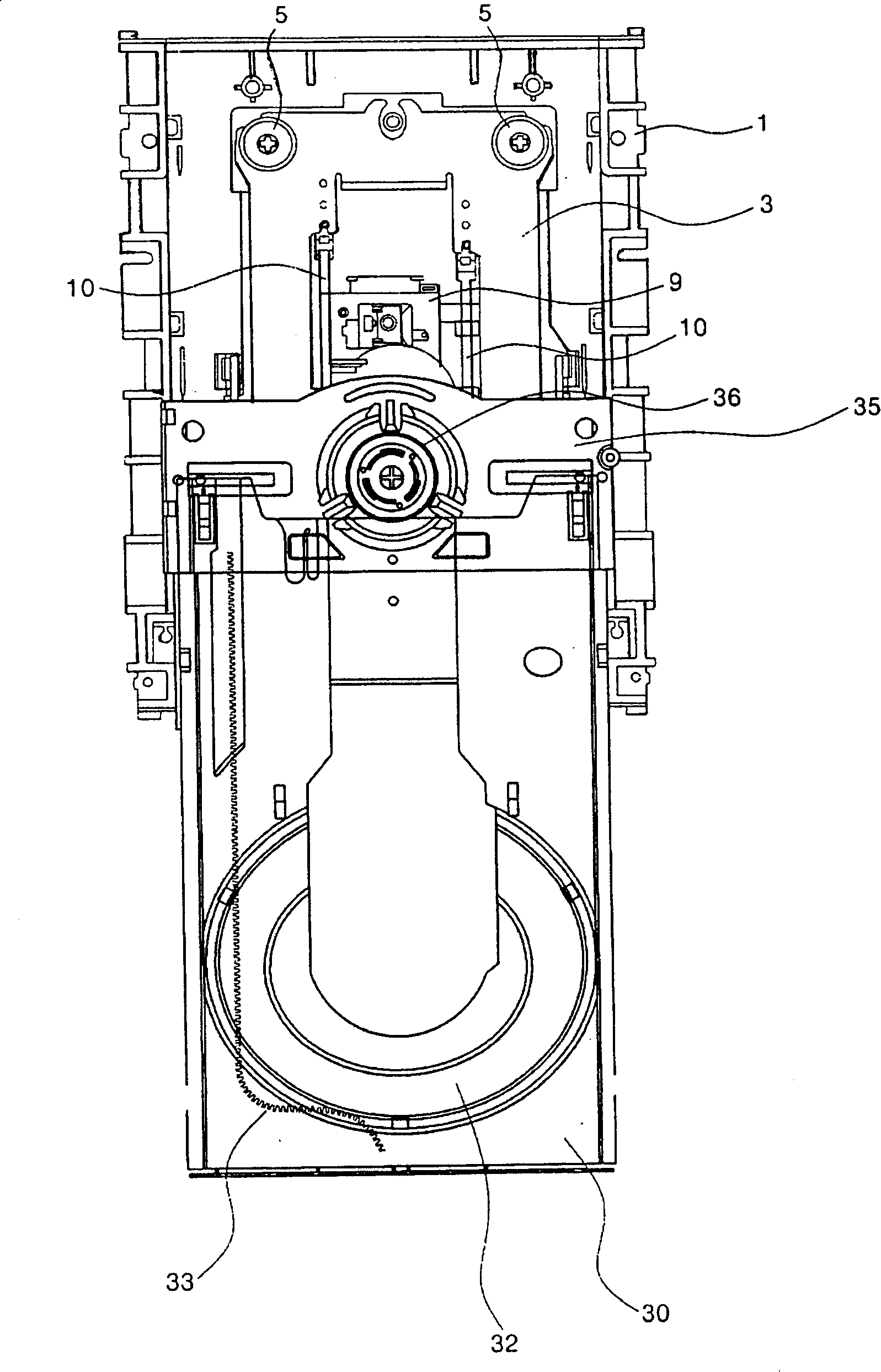

[0061] image 3 The configuration of the optical disc drive according to the present invention is shown schematically in plan. Figure 4 The structure of the pallet which constitutes the example of this invention is shown schematically in plan.

[0062] As shown in the drawings, the main base 50 forms the skeleton of the optical disc drive, and is a part for mounting various components constituting the optical disc drive. In the present invention, the above-mentioned main base 50 is a quadrilateral when viewed in a schematic plan view, and the front-to-back width is relatively shorter than the left-to-right width. The above-mentioned main base 50 surrounds the remaining part except the front part of the optical disk drive according to a case (not shown).

[0063] An optical pickup base 52 is provided on the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com