Packaging method for cigarettes in carton

A packaging method and cigarette technology, which is applied in the direction of packaging, article rotation wrapping, etc., can solve the problems of high cost, heat-sealing film odor, power consumption, etc., and achieve the effects of low cost, no odor discharge, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

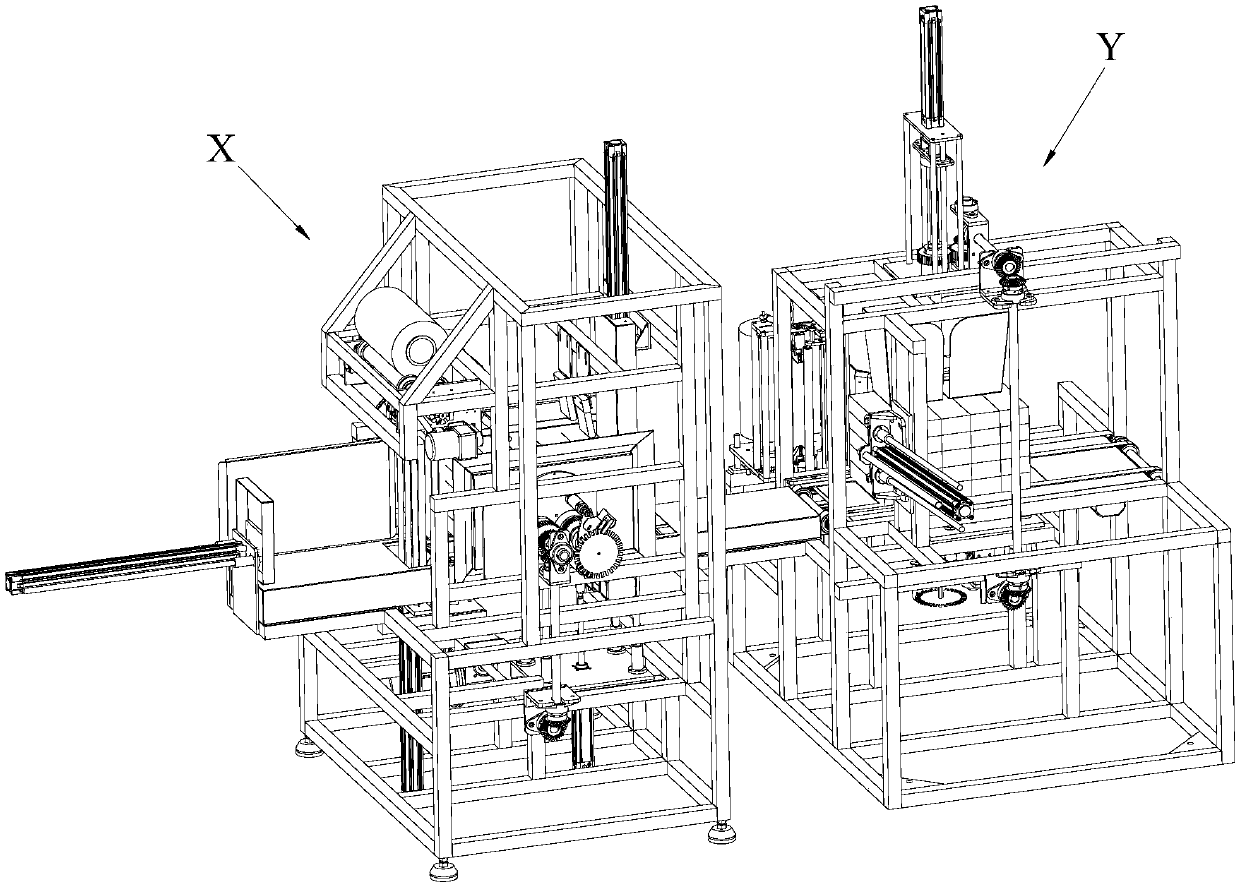

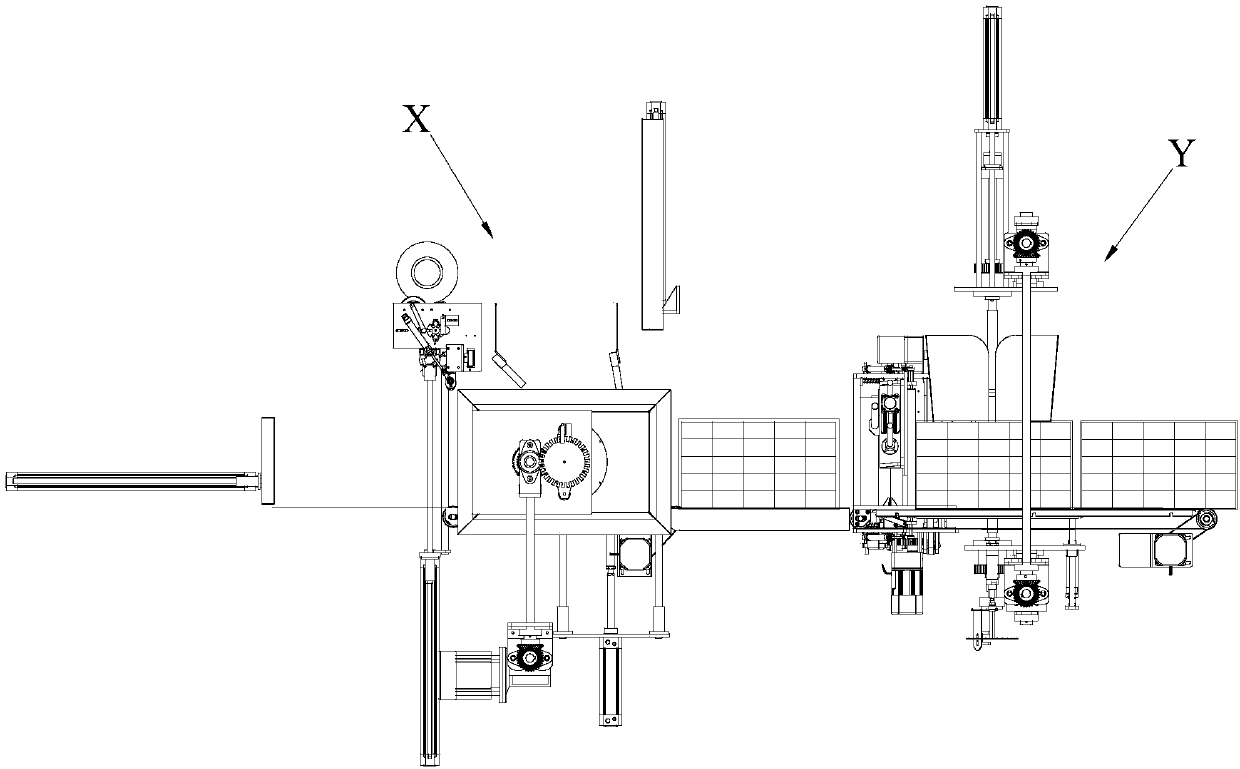

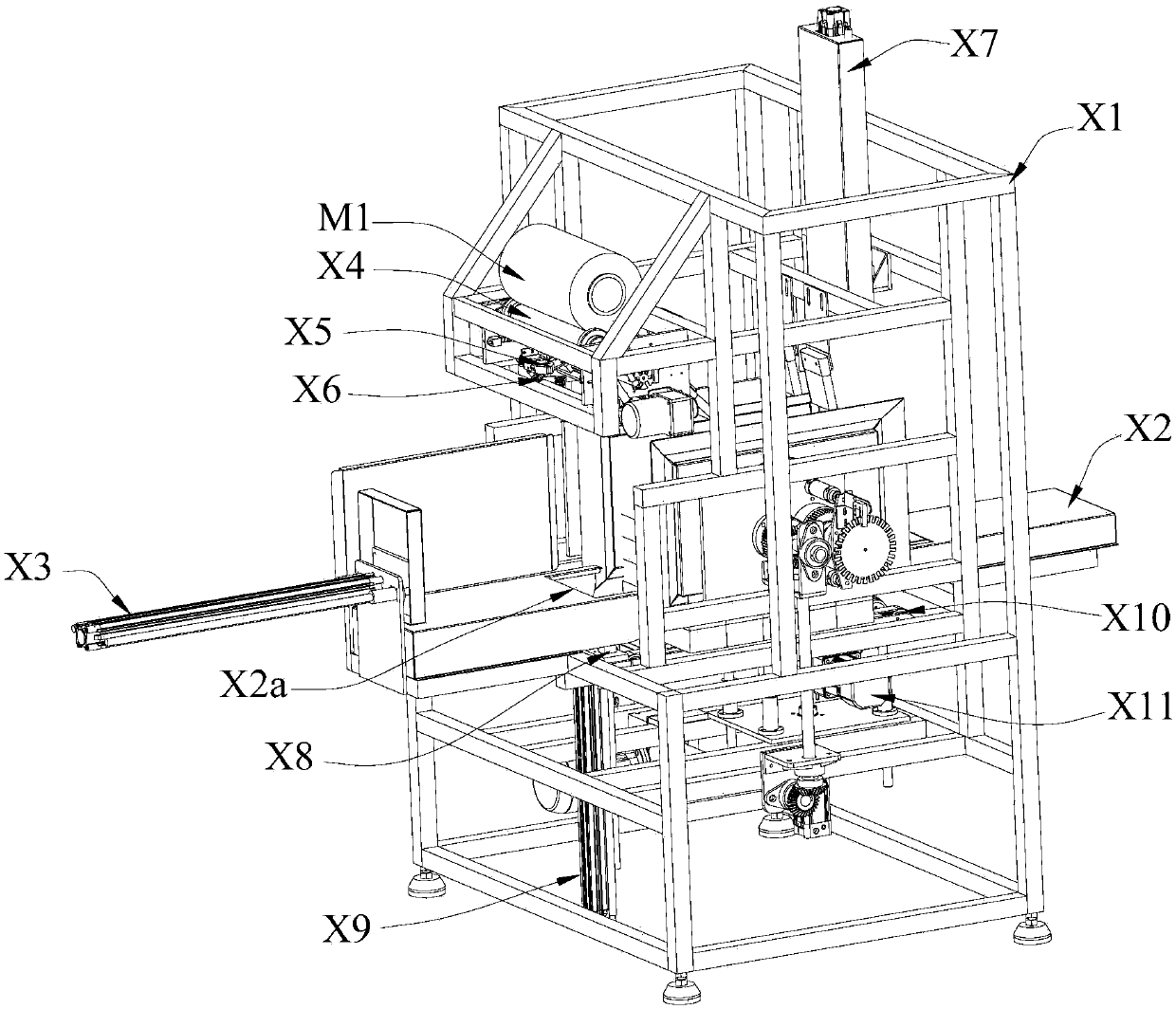

Image

Examples

Embodiment approach

[0044] As a preferred embodiment of the present invention: the stretch film is a PE film or a PVC film.

[0045] As a preferred embodiment of the present invention: the thickness of the stretch film is between 0.012mm and 0.018mm, the MD elongation of the stretch film is between 50% and 350%, and the viscosity of the stretch film is between 2N / 10cm and 25N / 10cm between.

[0046] As a preferred embodiment of the present invention: the packaged cartons include one or more cartons, and when the packaged cartons include multiple cartons, each carton is stacked into a rectangular cuboid Cigarette (C) is then wrapped and wrapped.

[0047] As a preferred embodiment of the present invention: the wrapping wrapping method is an active winding method or a passive winding method; wherein, the active winding method is: the wrapping film does not rotate around the packaged cigarettes, and the packaged cigarettes rotate actively Make the stretch film wrap the packaged cigarettes; the passive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com