Automatic silk stocking packaging production line

An automatic packaging and production line technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as increased labor intensity of workers, increased human resource costs, lack of automatic packaging, etc., to achieve smooth overall operation, low efficiency, and improved The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

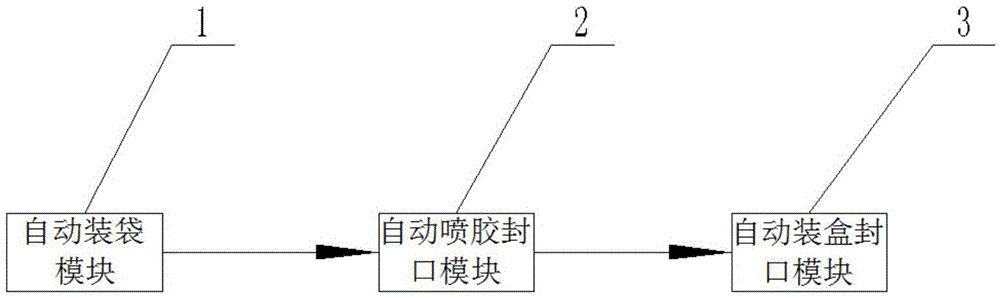

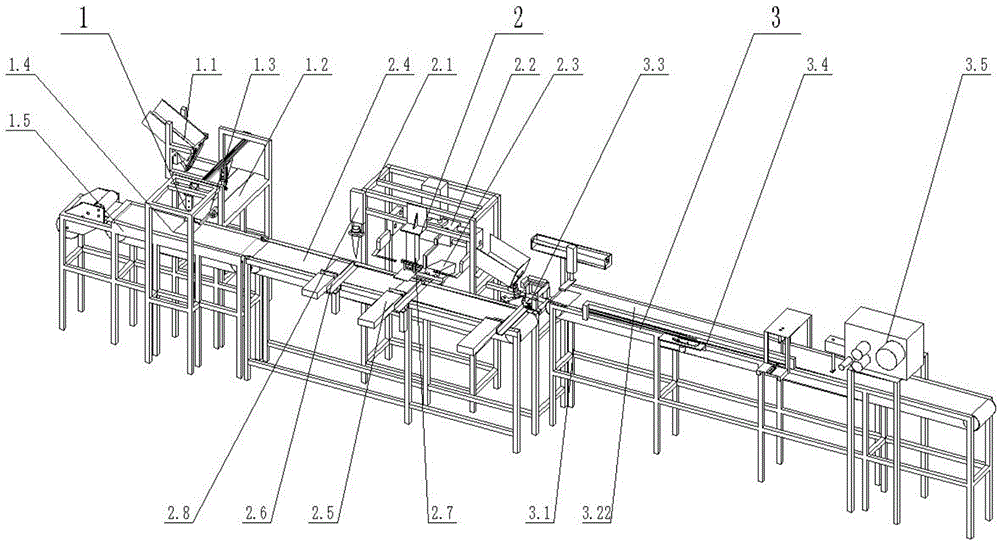

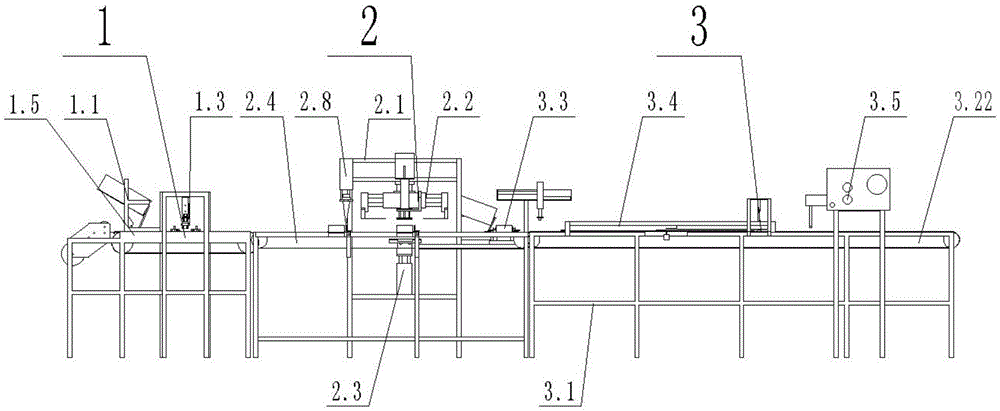

[0071] The embodiment of the present invention provides a structural principle diagram of an automatic packaging production line for stockings, see figure 1 .

[0072] An automatic packaging production line for stockings provided by the present invention includes an automatic bagging mechanism 1, an automatic glue spraying and sealing mechanism 2 and an automatic boxing and sealing mechanism 3, and the stockings pass through the above mechanisms sequentially on a conveyor belt;

[0073] The automatic bagging mechanism 1 is used to automatically send the stockings into the packaging bag after being folded on the cardboard;

[0074] The automatic glue-spraying sealing mechanism 2 is used for spraying glue to the mouth of the packaging bag of stockings and sealing it automatically;

[0075] The automatic box-packing and sealing mechanism 3 is used to automatically pack the packaging bags into the stockings into the carton and seal them automatically. The integral structure of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com