Modular automatic fast food packing machine

A modular and fast food technology, which is applied in the directions of packaging, wrapping objects, transportation and packaging, etc., can solve the problems of low packing efficiency and unhygienic packing, and achieve the effects of enhancing meal supply capacity, improving hygiene, and saving labor and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

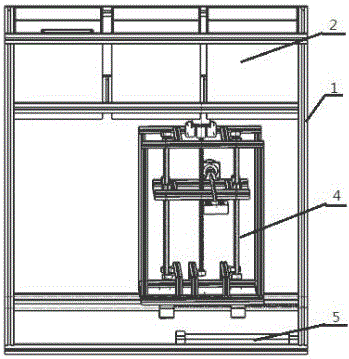

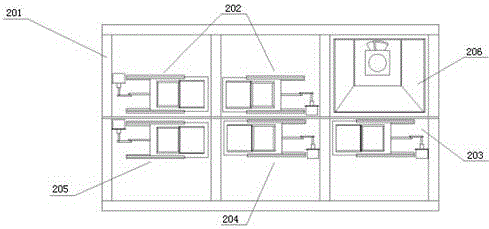

[0032] In this embodiment, a stack of lunch boxes is set on the left side, the collection area is in the middle, and the right end is plastic-sealed, and the opening button on the workbench 3 is manually pressed, the power is turned on, and the vegetable selection buttons on the workbench are pressed sequentially. The control system works, the motor B405 drives the longitudinal screw 406 to rotate forward, the tray 401 descends from the initial position, the infuriating pump works when it touches the lunch box, the vacuum suction cup 402 sucks the lunch box, and the motor B405 drives the longitudinal screw 406 to reverse Rotate, the tray 401 rises, and the motor C407 drives the forward screw mandrel 408 to rotate simultaneously so that the tray 401 turns over for half a circle, and the front of the lunch box is upward. After the tray 401 rises to the set height, the motor B405 stops, and the motor A drives the horizontal screw to rotate forward to move the tray 401 to the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com