Slice material automatic feeding device

An automatic feeding and material technology, applied in packaging, conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity, large labor occupation, low efficiency, etc., to save manpower, easy to use and maintain, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

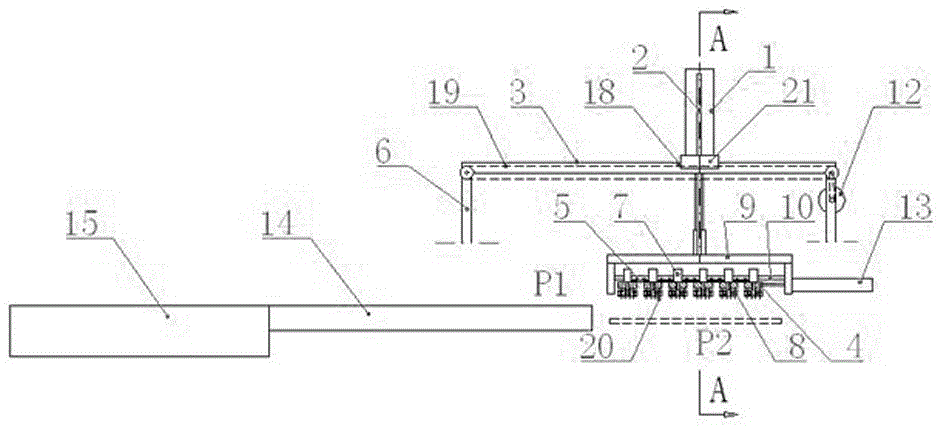

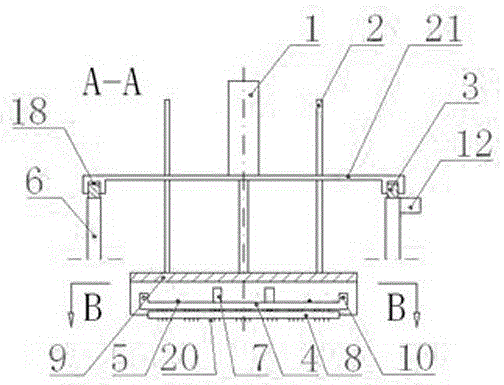

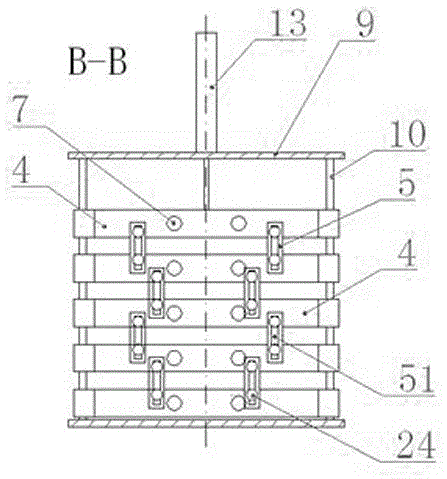

[0017] see Figure 1 to Figure 6 , an automatic feeding device for sheet materials in the present invention, comprising a spiral vibrating plate 15 and a flat plate vibrator 14, one end of the plate vibrating plate 14 is docked with the spiral vibrating plate 15, it is characterized in that, in the flat vibrating plate 14 A material grabbing device is provided above the other end.

[0018] The material grasping device includes a translation component and a grasping component, the grasping component is installed on the translation component, and the translation component drives the grasping component to move along the moving direction of the material on the plate vibrator 14;

[0019] Described translation assembly comprises frame 6, track 3, servo drive device 12, linear bearing 18, synchronous belt drive mechanism 19 and moving crossbeam 21, two rails 3 are arranged on the top of frame 6 in parallel and horizontally, and the two sides of moving crossbeam 21 The end is slidab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com