Wire packing and classifying equipment

A technology for sorting equipment and wires, which is applied in the field of wire packaging and sorting equipment, and can solve the problems of cumbersome packaging process, manual packaging, and low packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

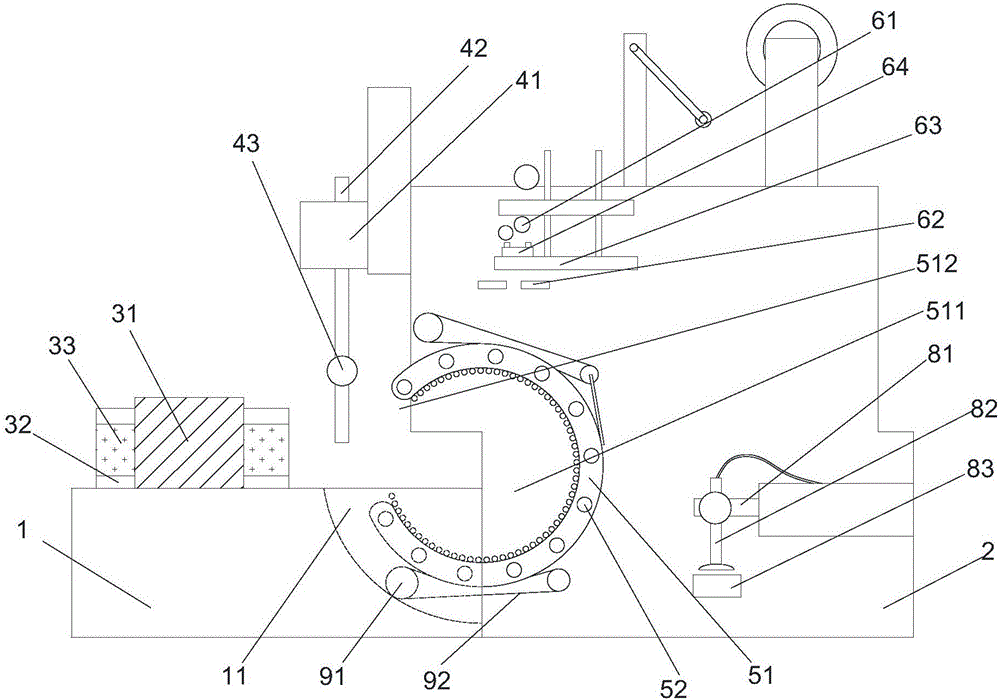

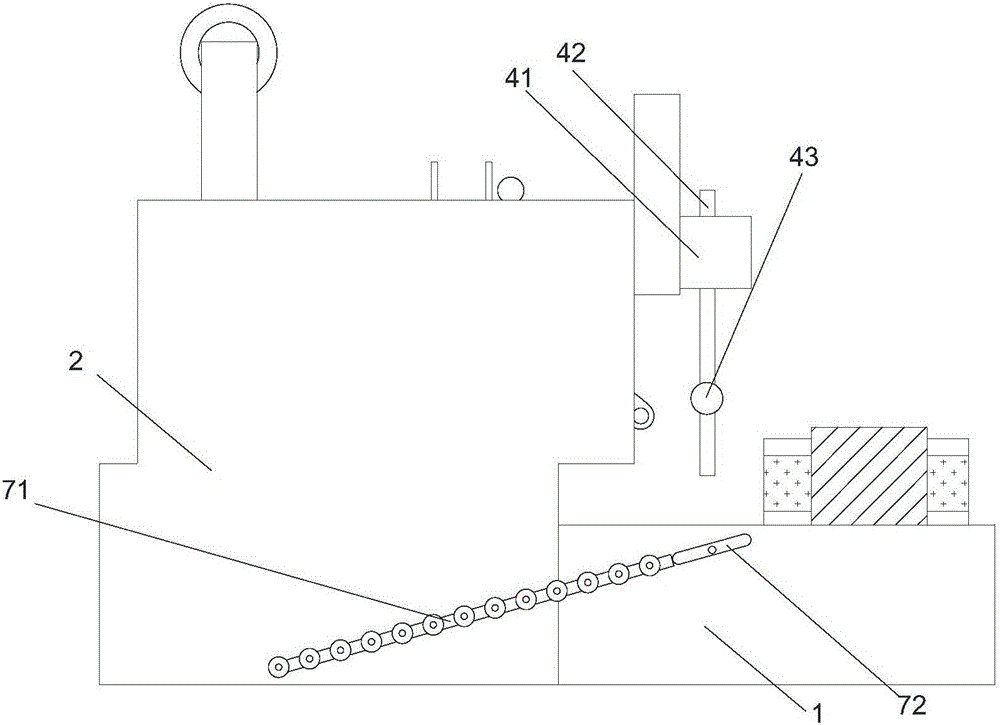

[0020] refer to figure 1 and figure 2 As shown, a wire packaging and sorting device proposed by the present invention includes a workbench 1, a mounting frame 2, two clamping mechanisms, a wire feeding mechanism, a packing mechanism, a belt feeding mechanism, a sorting mechanism, a labeling mechanism and a C-shaped frame Turn assist mechanism.

[0021] One side of the workbench 1 is provided with a work tank 11, and the installation frame 2 is installed on one side of the workbench 1 and corresponds to the position of the work tank 11;

[0022] The clamping mechanism includes a sliding seat 31, two clamping blocks 32 and two conveyor belts 33, the sliding seat 31 is movably installed on the workbench 1, the moving direction of the sliding seat 31 is the horizontal direction, and the first of the two clamping blocks 32 Both ends can be rotatably connected to the sliding seat 31, the rotation of the two clamping blocks 32 can make the second ends of the two clamping blocks 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com