Reinforcement steel sheet cutting belt-carrying packaging machine

A technology for reinforcing steel sheets and packaging machines, applied in packaging, feeding devices, positioning devices, etc., can solve the problems of low production and packaging efficiency of reinforcing steel sheets, troublesome processes, and damage to steel sheets, saving labor, The effect of reducing packaging costs and avoiding contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

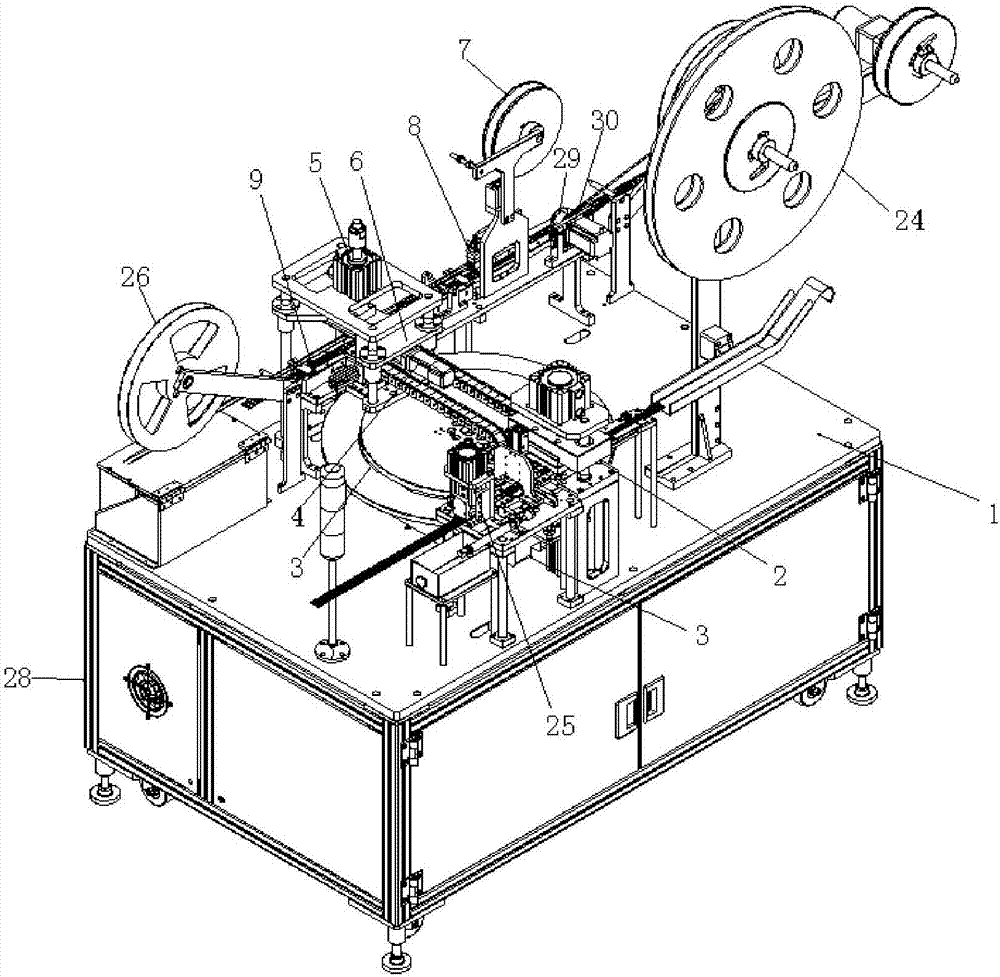

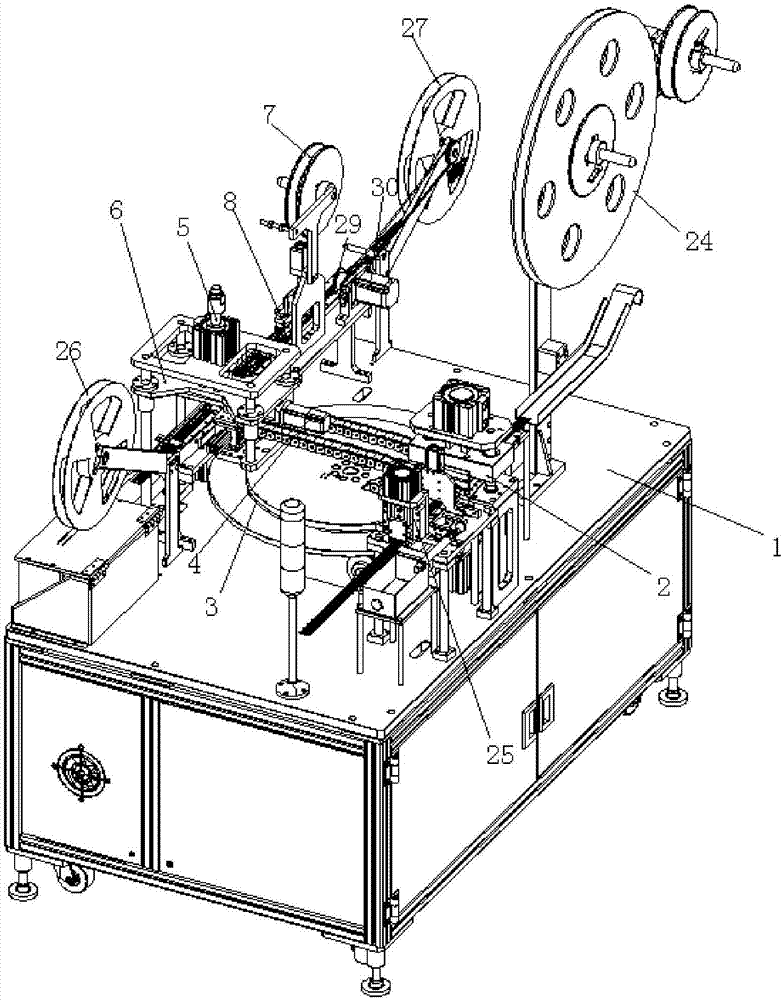

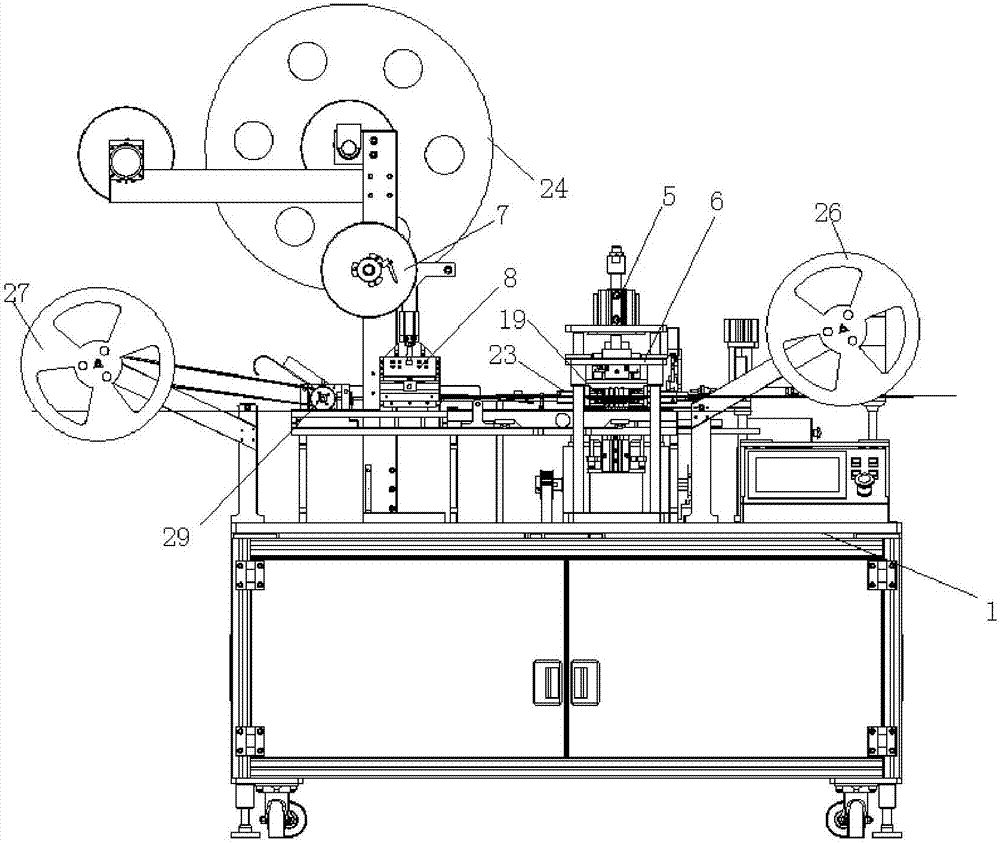

[0026] Embodiment: A reinforced steel sheet cutting carrier tape packaging machine, including a workbench 1, a steel sheet material belt feeding device, a steel sheet cutting mold 2, a first steel sheet grabbing device, a divider module 3, a second Two steel sheet grabbing devices, horizontal driving device 4, lifting driving device 5, sliding plate 6, material box material belt feeding device, heat sealing tape material tray 7, heat sealing module 8 and controller 28, the divider module Group 3 is installed on the workbench 1. Positioning devices are respectively provided on the upper sides of the divider module 3. The workbench 1 is located on the outside of one end of the divider module 3. There is also a material box material belt conveying channel 9, and the material box material belt is fed The device conveys the material box material belt and slides along the material box material belt feeding device, and the heat-sealing tape material tray 7 is rotatably installed above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com