Material arrangement mechanism of automatic toothpick packer

An automatic packaging machine and toothpick technology, applied in packaging, packaging sterilization, transportation and packaging, etc., can solve problems such as empty bags, affecting product quality, and being difficult to apply, achieving accurate control, preventing secondary pollution, and ensuring safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

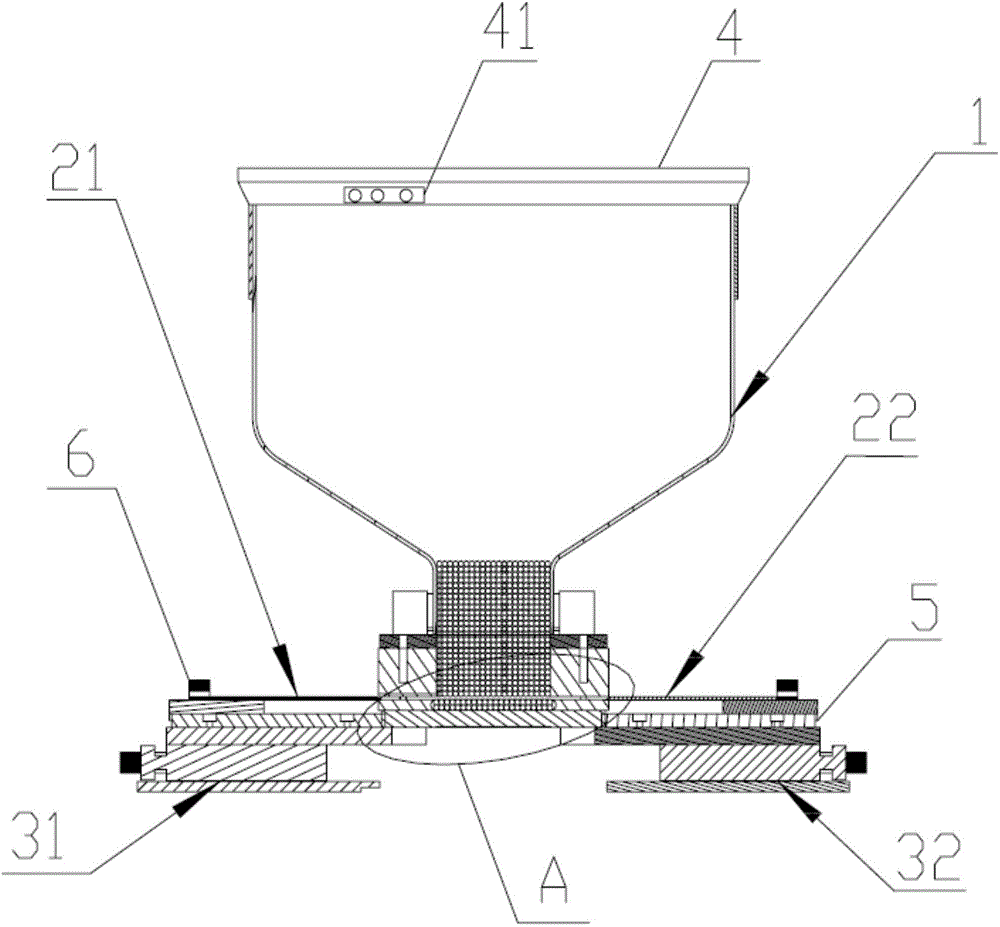

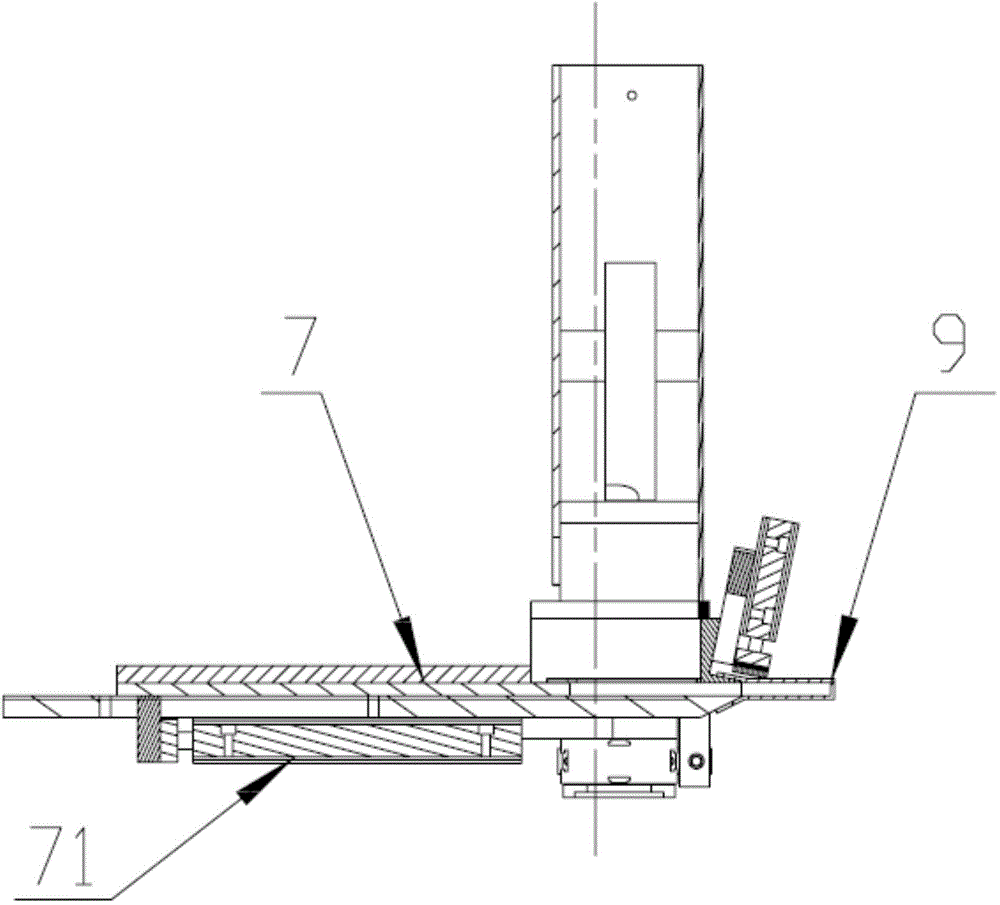

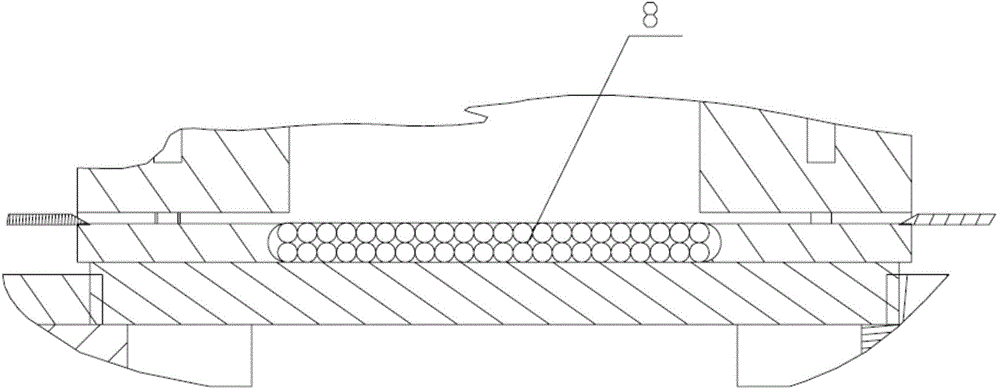

[0028] refer to figure 1 , figure 2 , image 3 As shown, the whole material mechanism of the toothpick automatic packaging machine includes a material storage device, a positioning device and a power unit, and the described material storage device is composed of a feed bin 1 and a sealing cover 4, and the described positioning device is composed of a positioning left plate 21 and a The positioning right plate 22 is formed, the power device includes a left pneumatic actuator 31 and a right pneumatic actuator 32, the positioning device is fixed in the chute of the work table 5, the power device is installed on the bottom of the work table 5, the positioning device and the power The device is connected through pipelines; the material storage device is fixed on the worktable 5, and a pusher plate 7 is arranged between the worktable 5 and the positioning device, and a pneumatic actuator 71 controls the movement of the pusher plate 7.

[0029] Preferably, the positioning left pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com