Bagging packaging method for long material and bagging packaging machine for long material

A packaging method and packaging machine technology, applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve the problems of inconsistent large-scale production requirements, low efficiency, and high labor costs, and achieve easy large-scale production, high degree of automation, The effect of low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

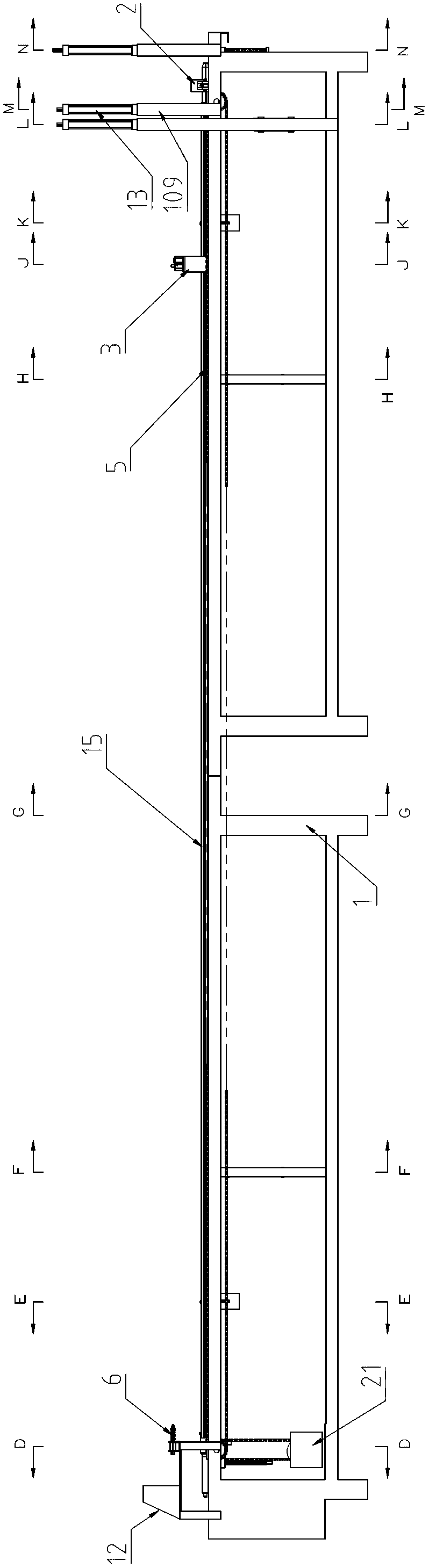

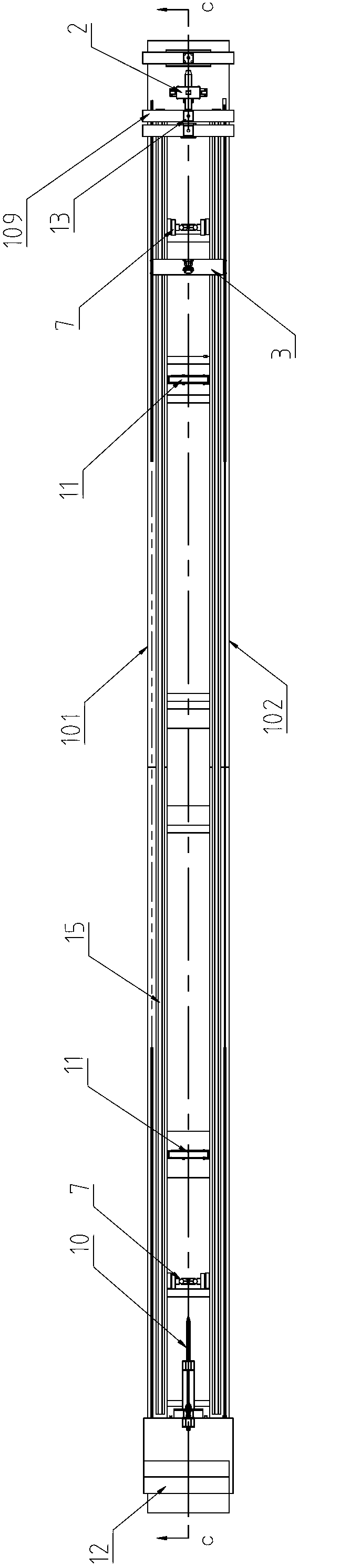

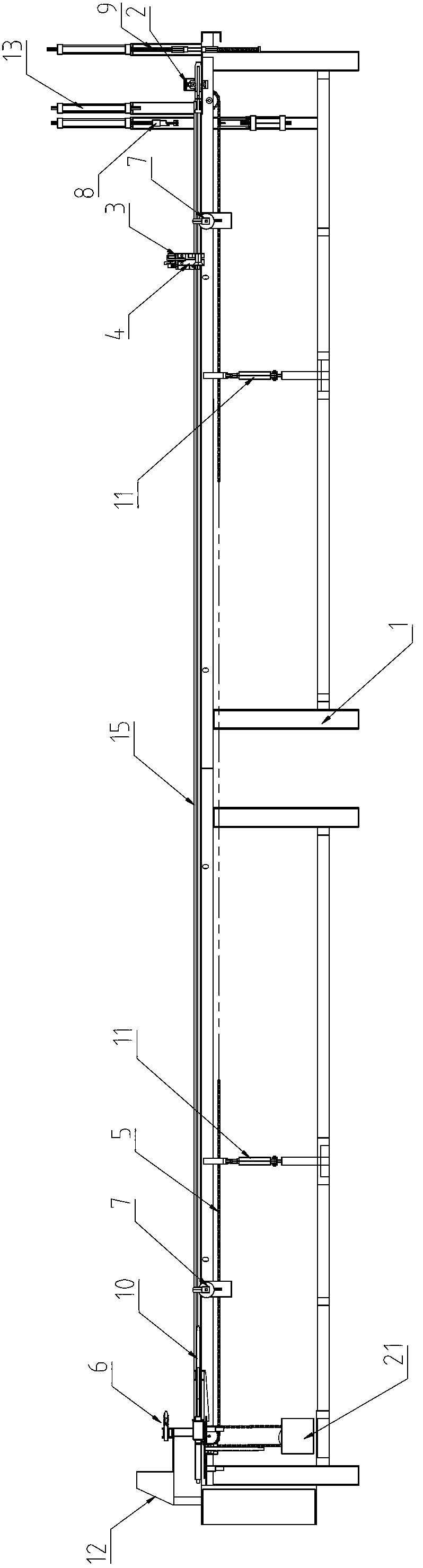

[0070] The structure of the embodiment 1 of the long material bagging packaging machine of the present invention is as follows: Figure 1 to Figure 34 shown.

[0071] The long material bagging packaging machine includes a frame 1, a bag supporting device 2, a bagging trolley 3, a bag clamping device 4, a guide rail pair composed of a guide rail 15 and a slider 14; a stepping motor, a reduction mechanism 21 and a traction chain 5 Composed of trolley drive mechanism; long material support frame 7, plastic bag cutting mechanism 8, bag return mechanism 9, long material longitudinal limit mechanism 10, discharge mechanism 11 and control panel 12 arranged at the rear end of the equipment.

[0072] Frame 1 comprises left longitudinal beam 101 and right longitudinal beam 102, and left and right guide rail 15 is respectively installed on the top surface of left longitudinal beam 101 and right longitudinal beam 102, and left and right slide block 14 is installed on the bagging dolly 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com