Method and a device for the assembly of packets for tobacco products

a technology for tobacco products and packaging, applied in the direction of packaging, packaging, transportation and packaging, etc., can solve the problems of packets being defective, their stability, and having to be discarded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

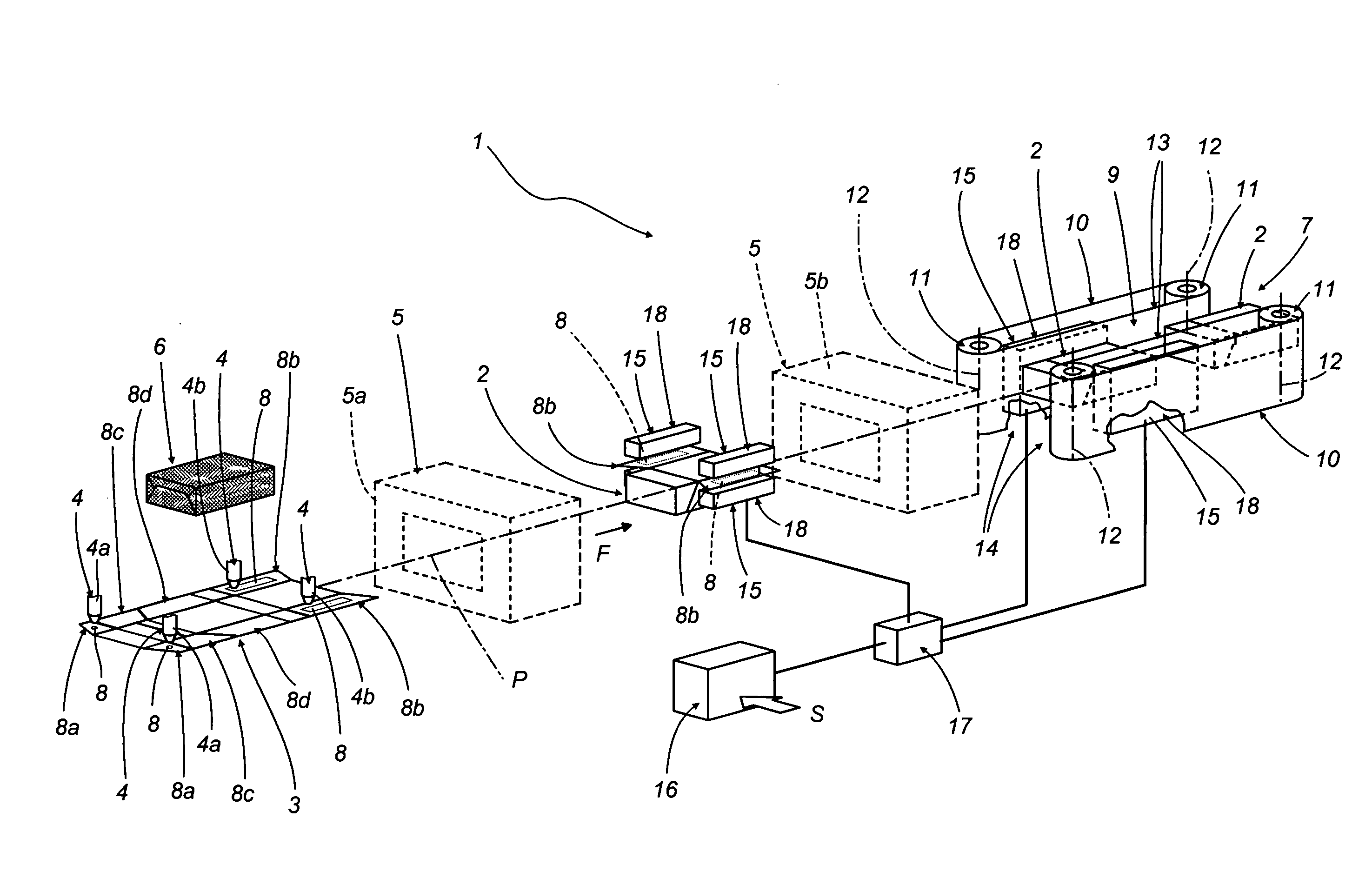

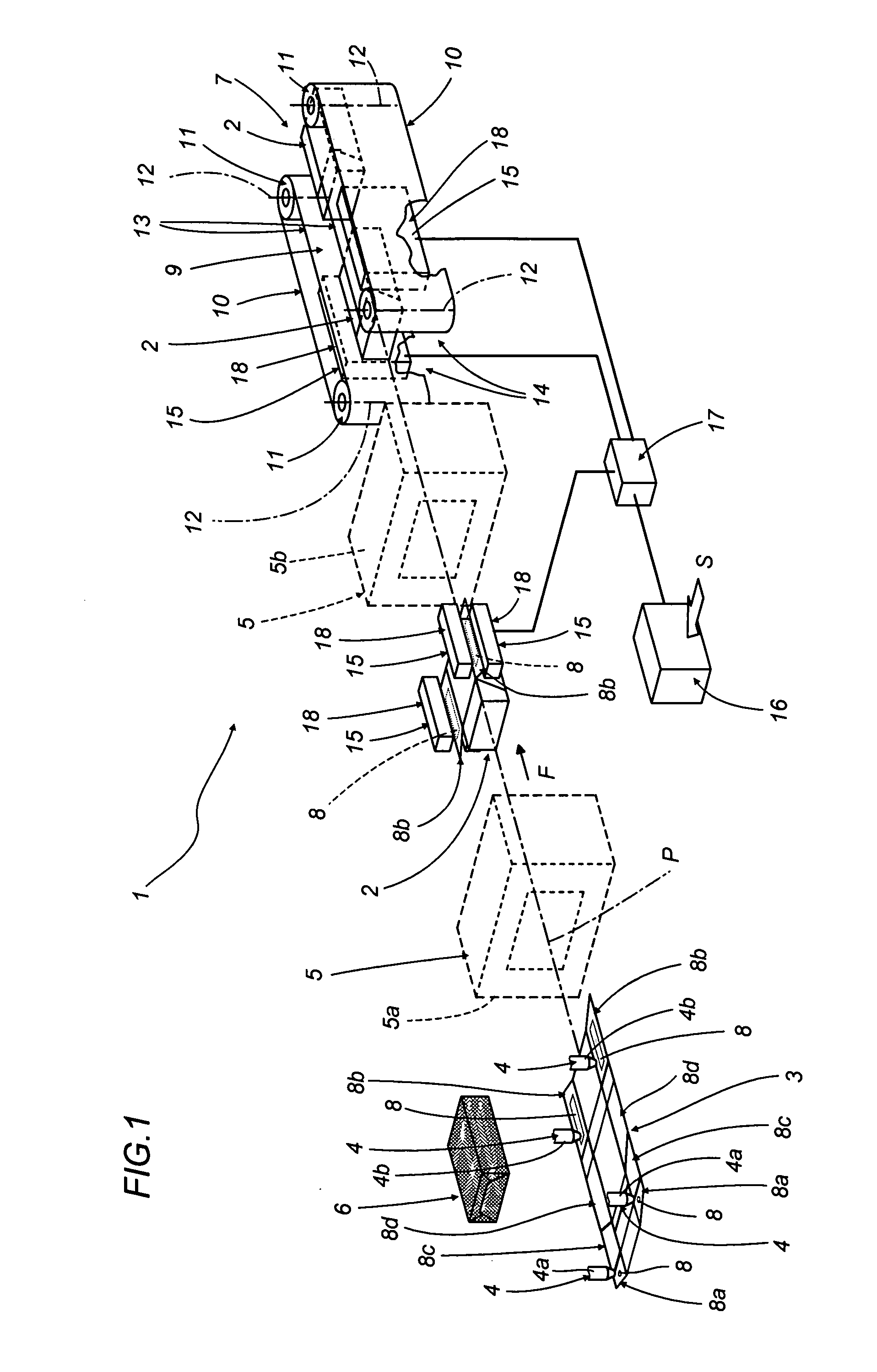

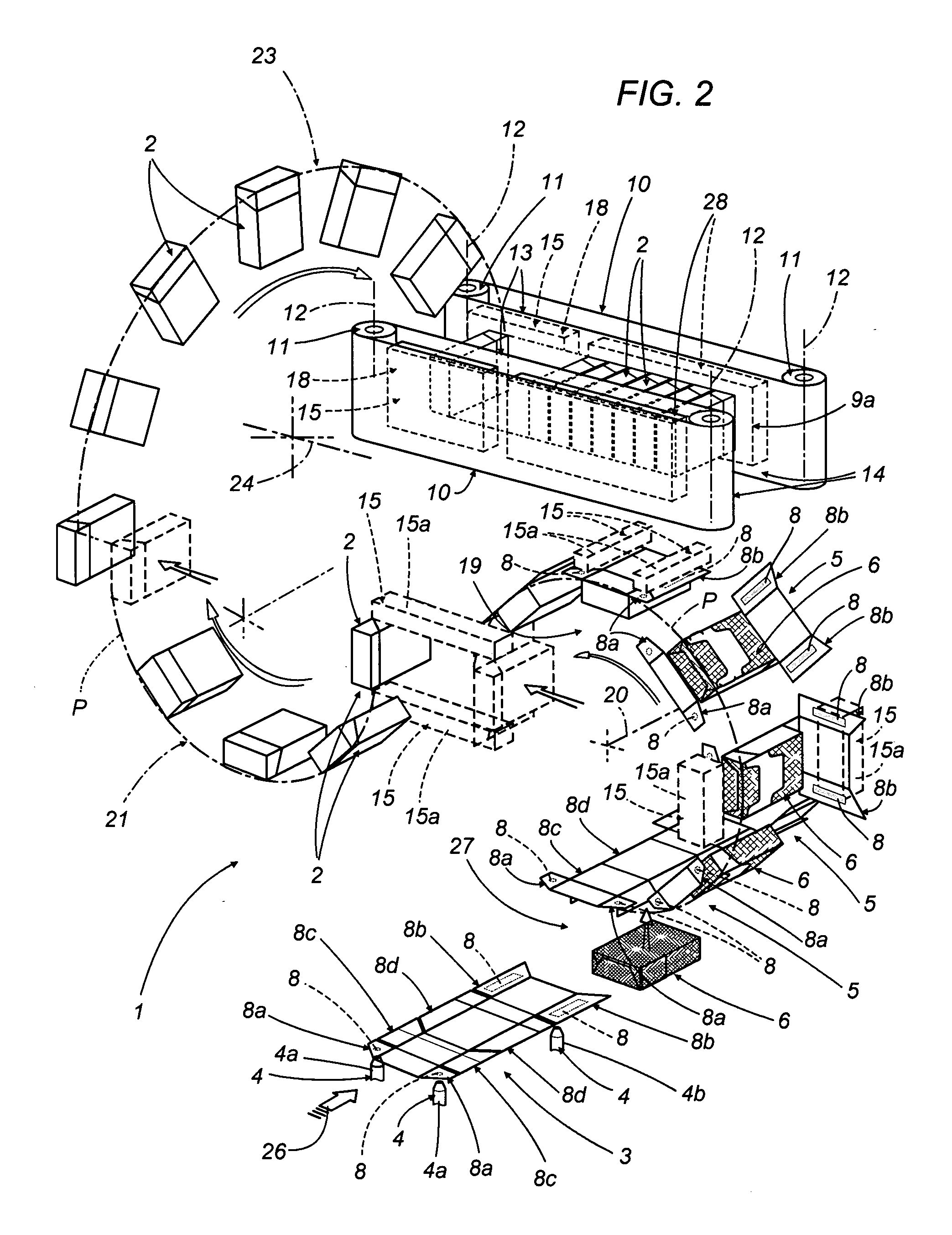

[0018] With reference to the drawings, numeral 1 denotes a portion of a wrapping line, in its entirety, on which packets 2 for tobacco products are assembled in a packaging machine.

[0019] The wrapping line follows a predetermined path P along which sheets 3 of wrapping material, referred to commonly as blanks, or diecuts, are caused to advance in succession by suitable feed means of conventional embodiment (not illustrated in the drawings), following a feed direction denoted F.

[0020] Located along the aforementioned wrapping path P are components 4 serving to apply a layer or dab of cold-setting adhesive, denoted 8, on selected areas of the wrapping material, and folding means 5 such as will fashion an enclosed packet about a relative group 6 of cigarettes already enveloped, typically, in a leaf of metal foil paper.

[0021] In the example of FIG. 1, the wrapping line 1 passes through a first and a second folding station illustrated schematically as two blocks 5a and 5b, positioned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| critical time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com