Method and device for manufacturing packaging for cigarettes

A packaging and equipment technology, applied in the field of clamshell box packaging, which can solve problems such as contamination of glued components and unsatisfactory patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

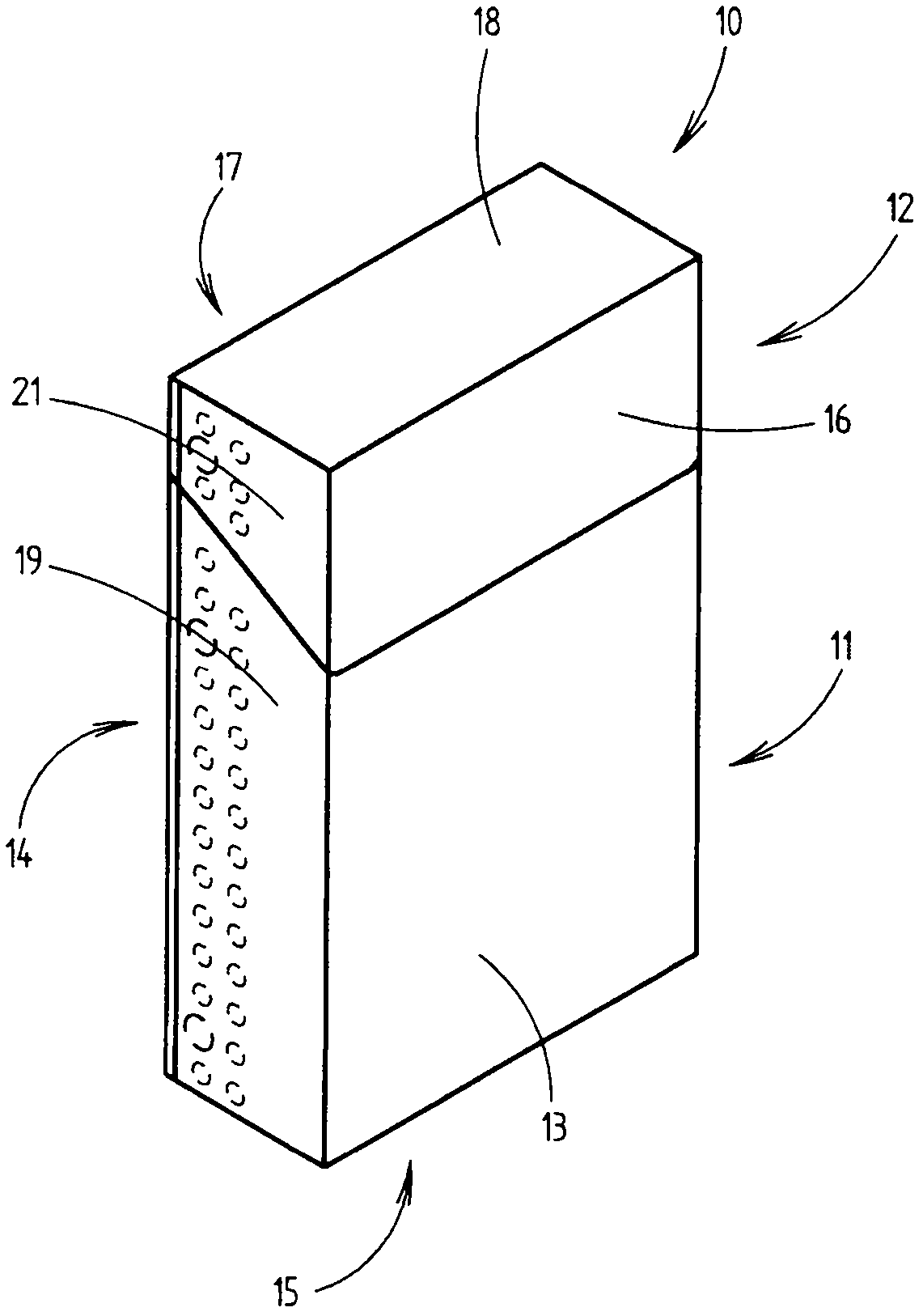

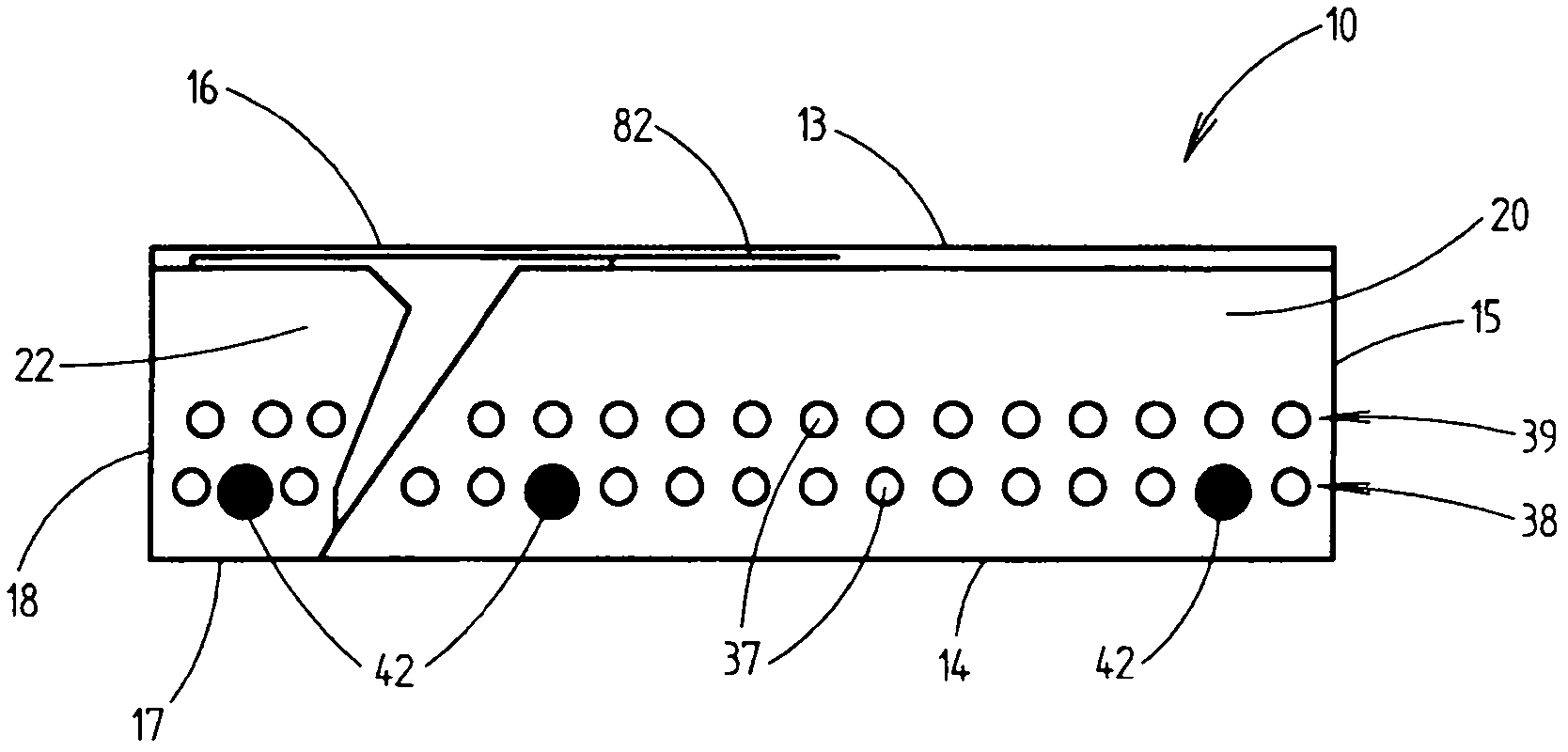

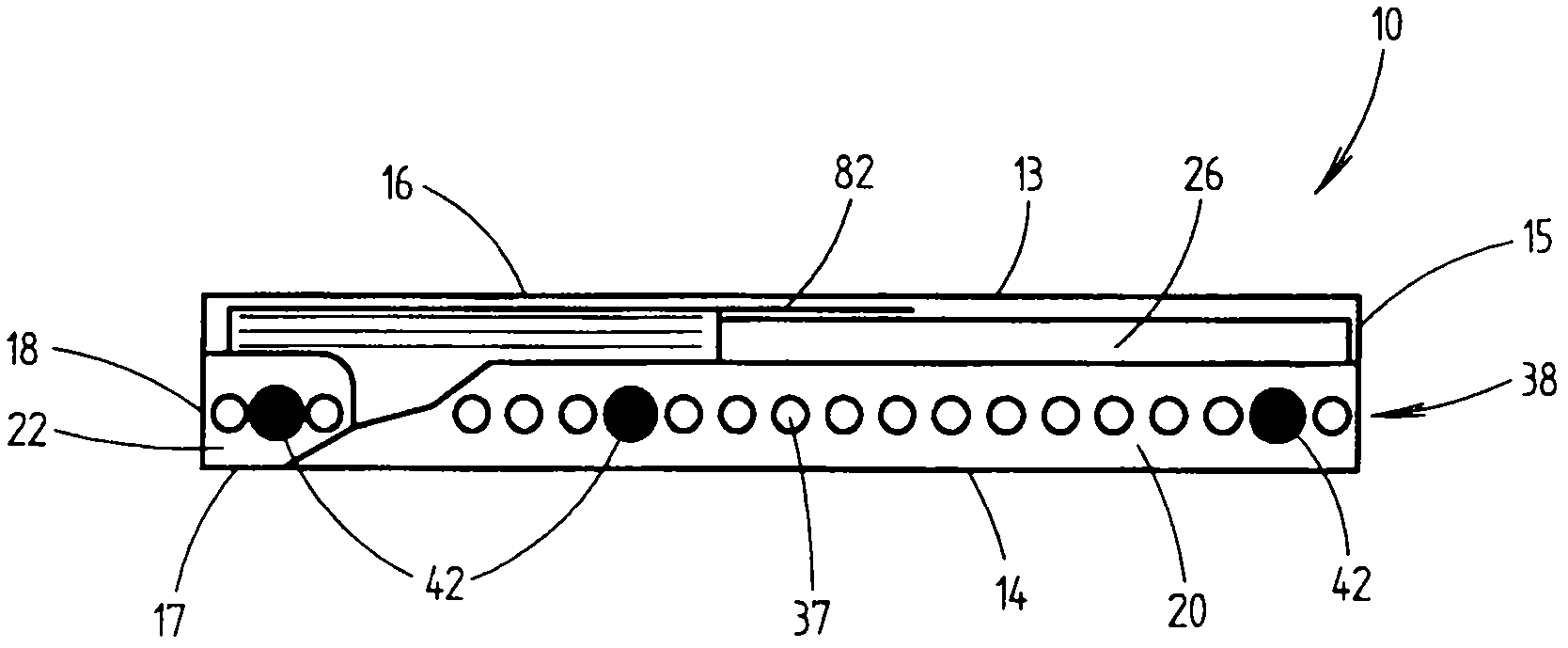

[0035] The figures show a preferred field of application, namely the production of flip-top box packs 10 for cigarettes. This type of package comprises a box part 11 and a cover 12 . The box part 11 has a box front wall 13 and a box rear wall 14 which are connected to each other by a bottom wall 15 . Cover 12 includes a cover front wall 16, a cover rear wall 17 and a cover end wall 18 therebetween.

[0036] On the one hand, the side walls of the package, that is to say the side walls of the box part 11 and on the other hand the side walls of the lid 12 each comprise two folding flaps which are completely or partially superimposed on one another. . The box outside flap 19 fits laterally on the box front wall 13 , while the box inside flap 20 fits laterally on the box rear wall 14 . Correspondingly, in the region of the lid 12 , the outer lid flap 21 fits on the lid front wall 16 and the inner lid flap 22 fits on the lid rear wall. The blank is folded such that on the one ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com