Automatic acupuncture needle tubing packaging machine

An automatic threading and packaging machine technology, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, to achieve the effect of stable and reliable automatic threading packaging operation and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

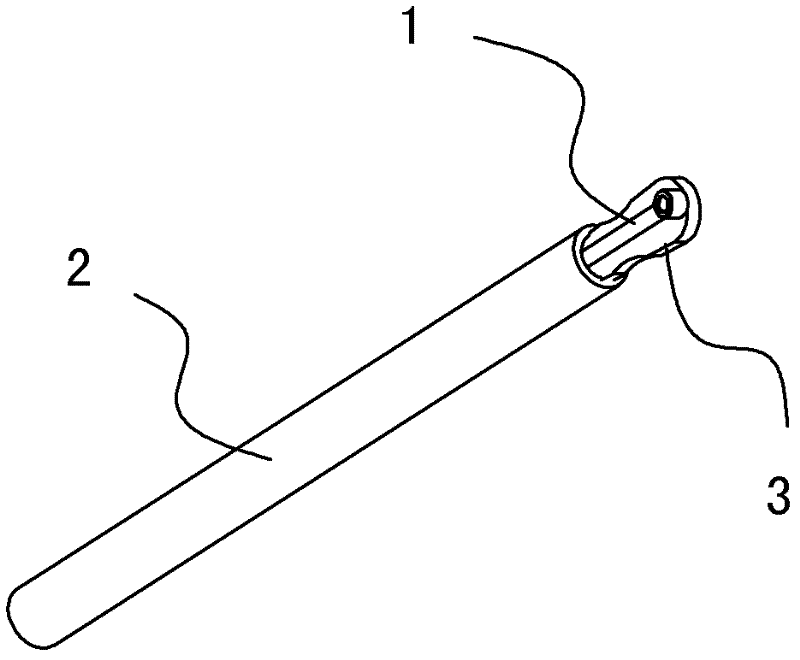

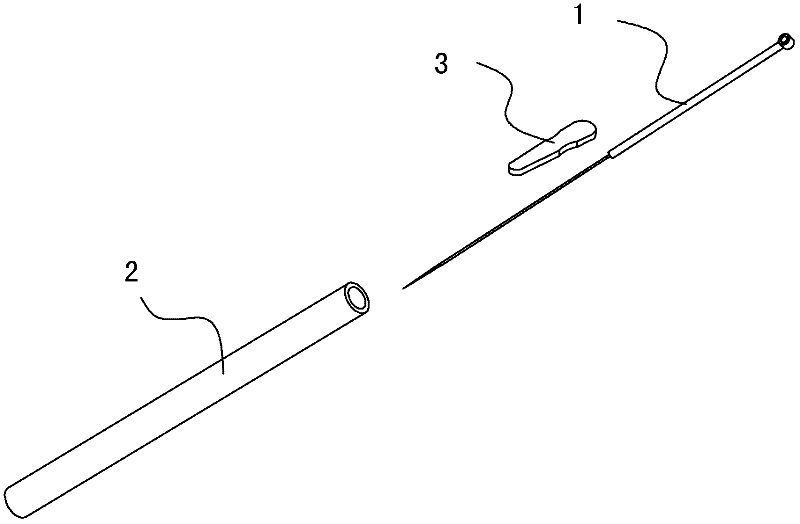

[0023] Example: An automatic tube-piercing packaging machine for acupuncture needles

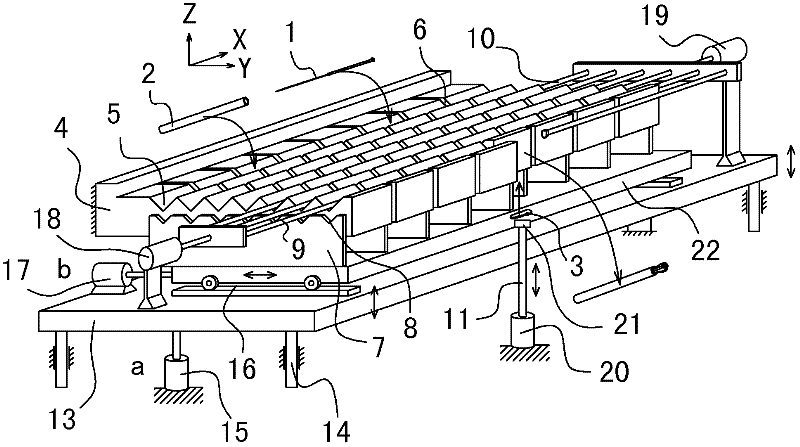

[0024] Such as image 3 As shown, the automatic tube-piercing packaging machine for acupuncture needles is mainly composed of a circulating feeding mechanism, a tube pushing mechanism, a needle pushing mechanism, and a sheet feeding mechanism. These institutions are described in detail below:

[0025] 1. Circulating feeding mechanism

[0026] See image 3 with Figure 4 , The circulating feeding mechanism has a V-groove support 4 arranged horizontally. For ease of description, it is now defined that the center of the V-groove support 4 is used as a reference, the horizontal left and right directions are the X-axis directions, the horizontal front and rear directions are the Y-axis directions, and the vertical up and down directions are the Z-axis directions. A set of V-shaped grooves 5 are opened on the top surface of the V-shaped support 4 along the X-axis direction. This group of V-shaped groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com