Automatic pipe packing machine

An automatic packaging machine and pipe technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of labor, affecting the effect of packaging, and large amount of film, so as to improve the quality of pipe packaging, improve packaging efficiency, and optimize packaging. effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

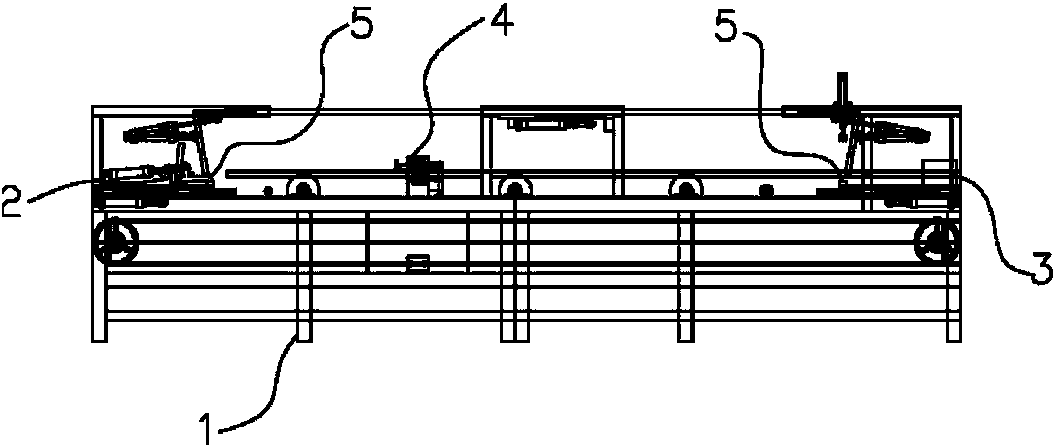

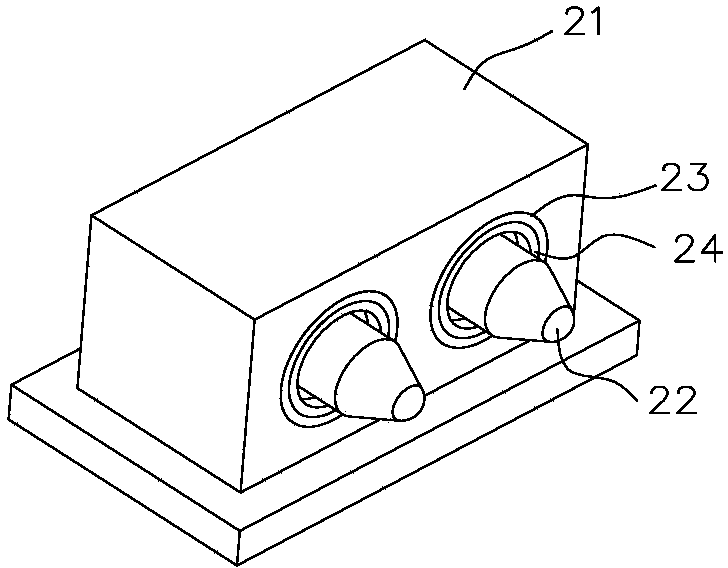

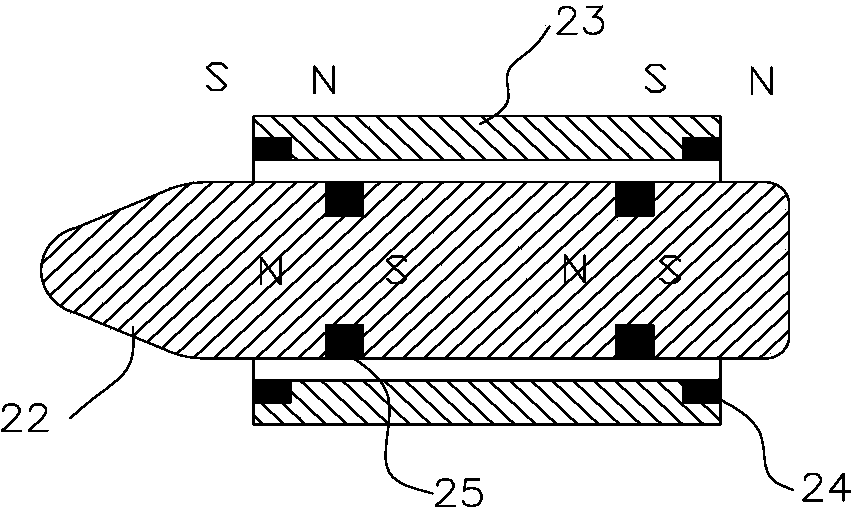

[0036] refer to Figure 1 to Figure 12 , a pipe automatic packaging machine, including a frame 1, also includes:

[0037] A magnetic levitation device 2 arranged at the front end of the frame 1 for stretching the packaging film; an inflator 3 arranged at the rear end of the frame 1 for floating the stretched packaging film above the pipe; arranged on the frame 1, The automatic film clamping device 4, which can move along the direction of placing the pipe, is used to clamp the packaging film to cover the pipe; the edge cutting and sealing device 5, which is located at the front and rear ends of the frame 1, is used to cut and seal the packaging film.

[0038] By using the automatic pipe packaging machine provided by the invention, the packaging process of the existing packaging machine is optimized, the pipe packaging efficiency is effectively improved, and the pipe packaging quality is improved. Moreover, the invention has a simple and reasonable structure, clear division of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com