Fully automatic ABS gear ring defect detection system based on machine vision

An ABS ring gear and machine vision technology, which is applied in the field of automatic ABS ring gear defect detection system, can solve the problems of detection efficiency and detection success rate drop, workers' physical injury, time-consuming and labor-consuming, etc., to save manpower and financial resources, Improve efficiency and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

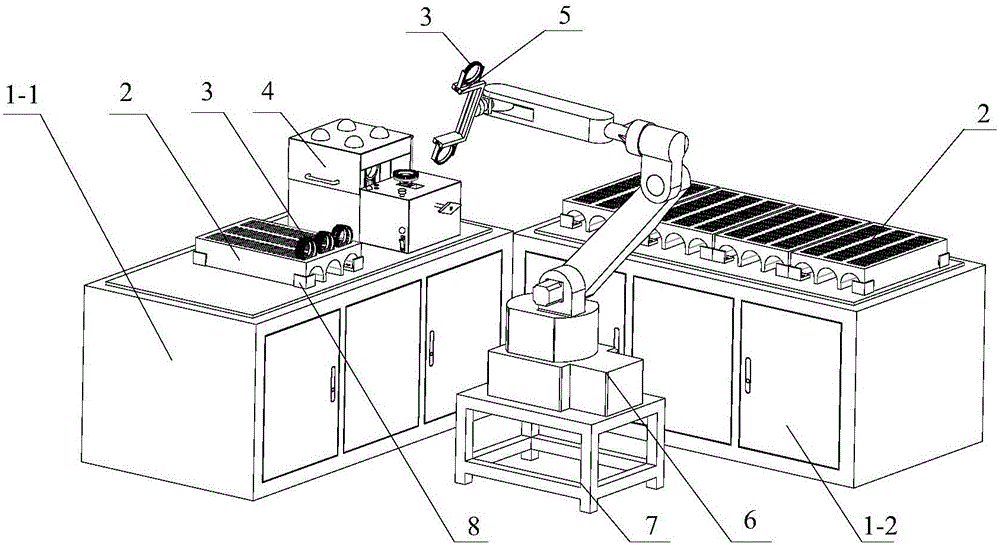

[0031] Such as figure 1 As shown, two workbenches 1 on the ground are placed vertically at right angles, the manipulator base 7 is located in the center, and the manipulator 6 is placed on the base 7, and the manipulator pneumatic clamp 5 is connected to the top of the manipulator 6, and the clamp 5 is used to clamp the ABS ring gear. 3. The loading frame 2 and the detection table 4 are placed on the workbench 1-1, and the unloading frame 2 is placed on the workbench 1-2, a total of 4, which are respectively used to place qualified, missing teeth, effusion and other 4 categories. All around each material storage frame 2, 4 material storage frame fixing frames 8 are fixed for spacing. The PC can be placed in a suitable position according to the actual situation of the factory, which is not shown in the figure.

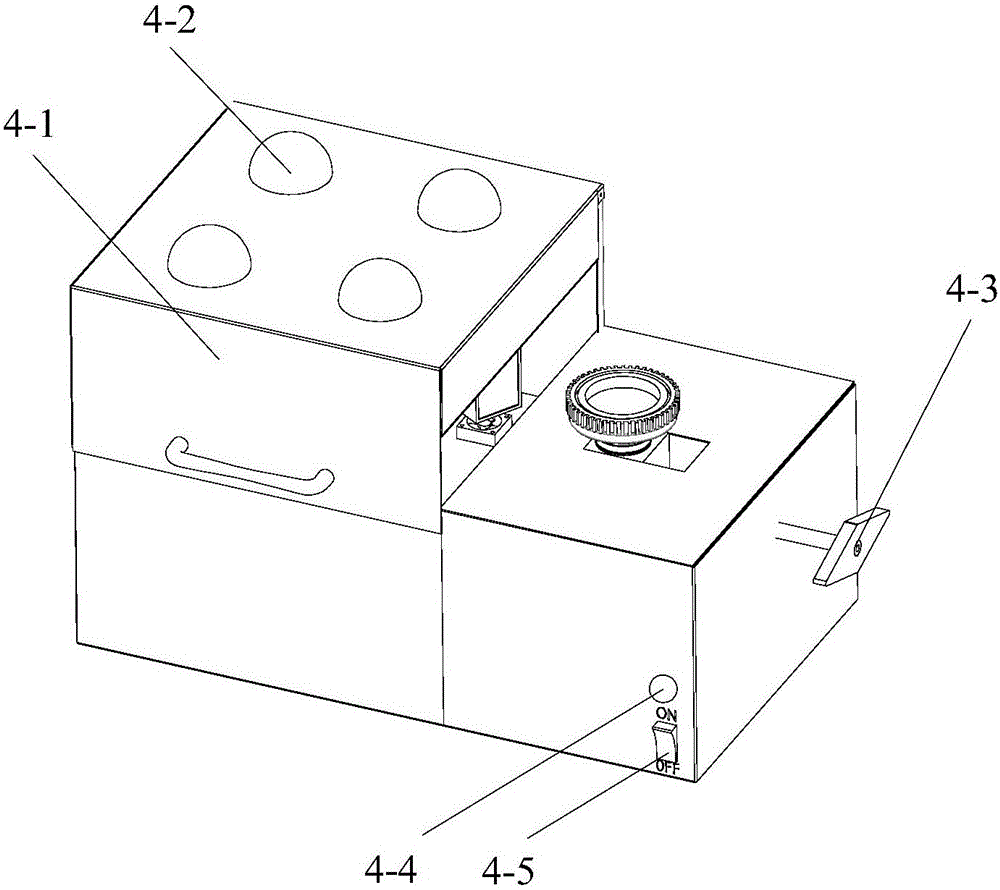

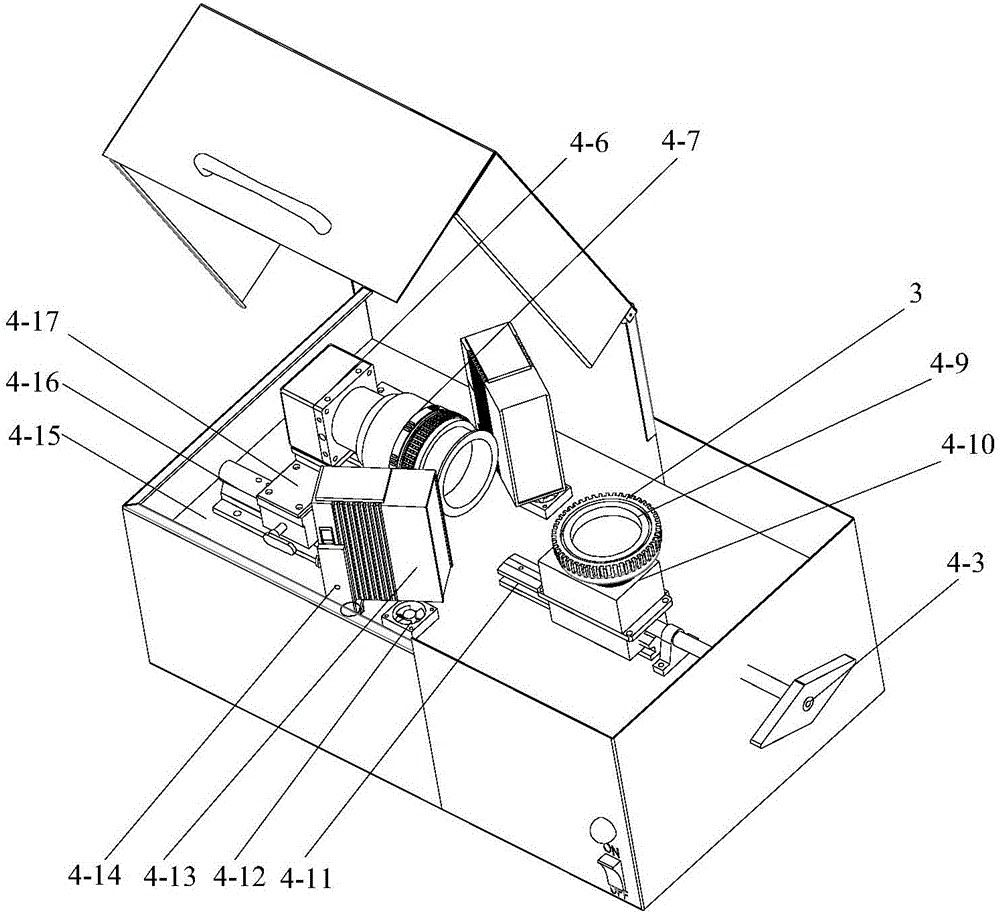

[0032] Such as figure 2 Shown is a three-dimensional schematic diagram of the testing platform, 4-1 is the outer shell of the testing platform, the top layer is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com