Automatic on-line vision detecting and sorting system and sorting method

An automatic detection and vision technology, applied in the field of visual inspection, can solve the problems of poor detection effect, time-consuming and laborious, low detection efficiency, etc., to reduce the probability of entering the market, improve production efficiency, and save memory space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention provides an online visual automatic detection and sorting system and a sorting method thereof. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention is further described below in detail. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

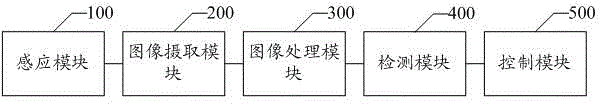

[0039] see figure 1 , figure 1 It is a structural block diagram of a preferred embodiment of the online visual automatic detection and sorting system of the present invention, as shown in the figure, including: a sensing module 100, an image capturing module 200, an image processing module 300, a detection module 400, and a control module 500, and the described The sensing module 100 , the image capturing module 200 , the image processing module 300 , the detection module 400 , and the control module 500 are connected in sequence.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com