Grinding ball separator

A sorting machine and grinding ball technology, which is applied in the field of wear-resistant ball production devices, can solve the problems of increasing labor intensity and reducing production efficiency, and achieve the effects of preventing jamming, improving production efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

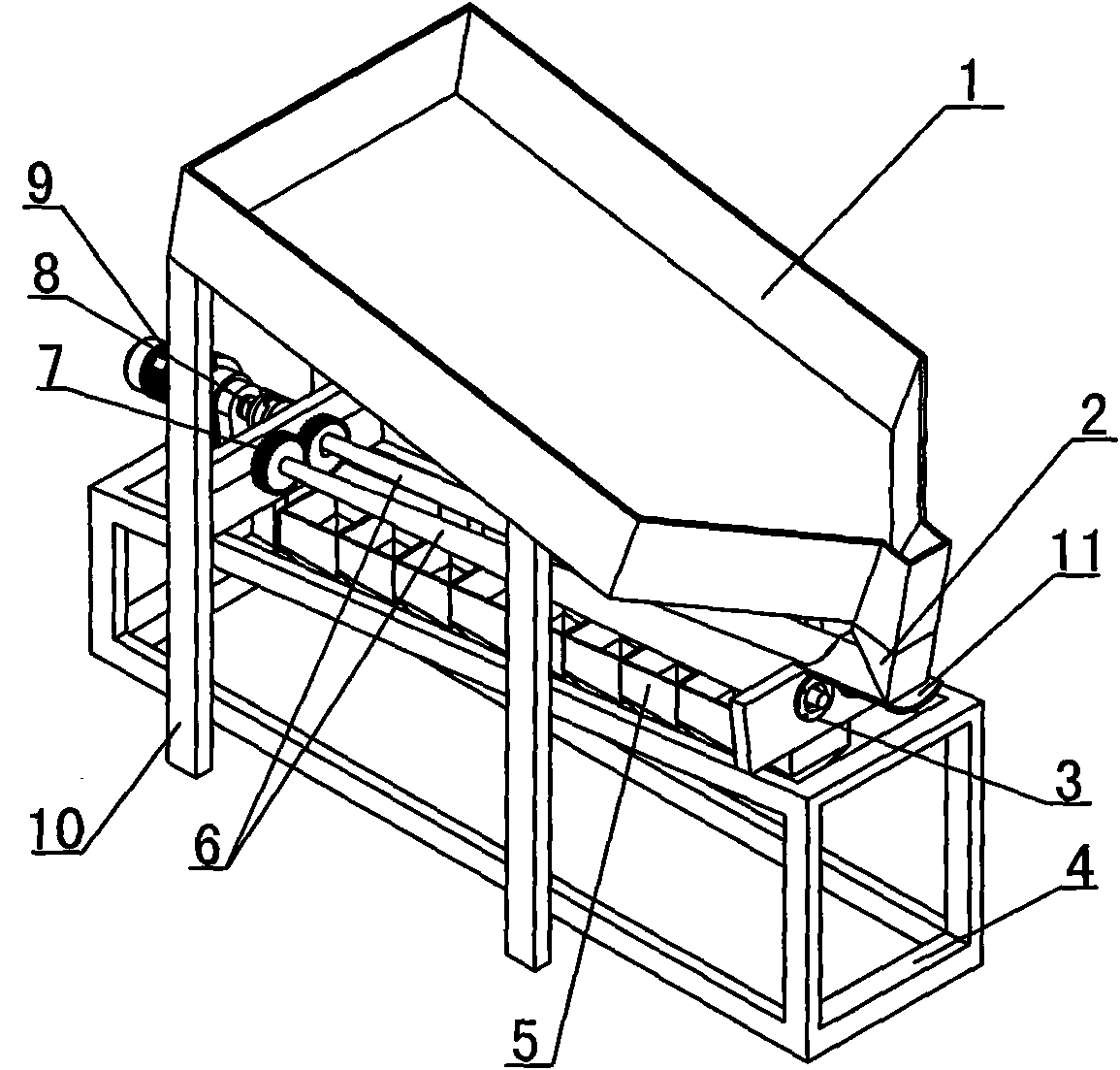

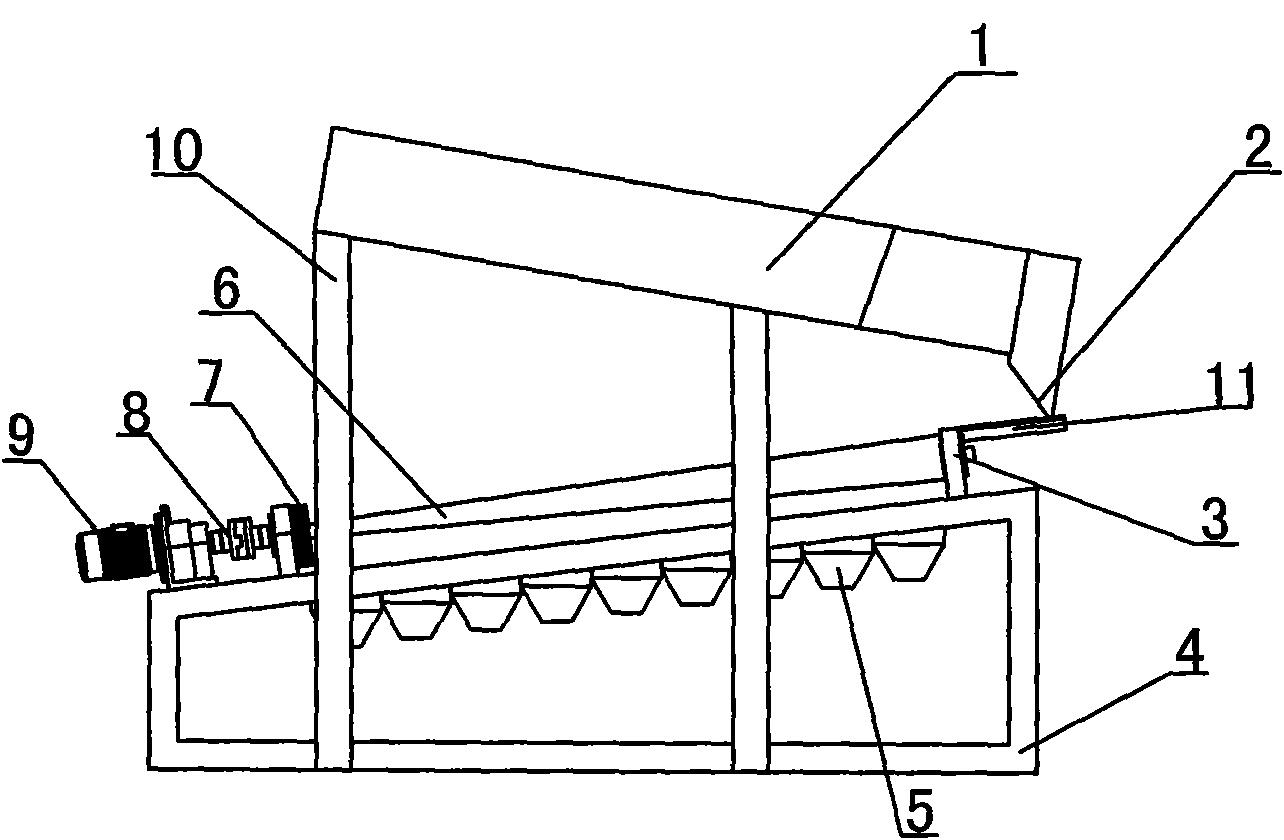

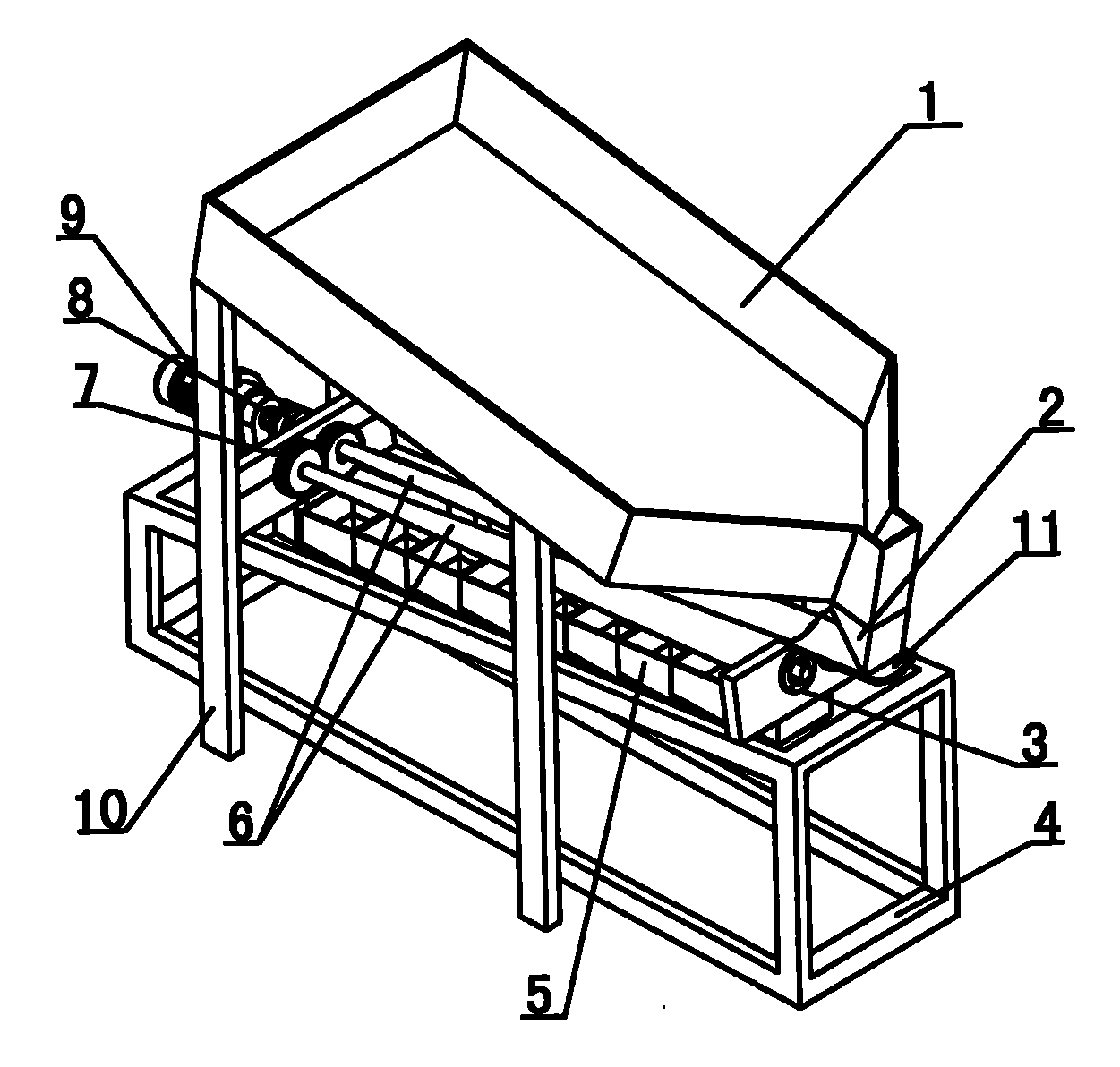

[0012] Such as Figure 1-2 As shown, the grinding ball sorting machine of the present invention is composed of a material storage box 1 and a separation mechanism. The material guide port 2 of the material pipeline, the lower side of the material guide port 2 is connected to the rolling plate 11; the two ends of the upper side of the machine base 4 are respectively installed with bearing mounting plates 3, and the two bearing mounting plates 3 are installed to form a certain distance gap The two tapered roller shafts 6, the thin ends of the two tapered roller shafts 6 are respectively connected to the coupling 8 through the gear transmission mechanism 7, and the end of the coupling 8 is connected to the reduction motor 9, which is located on the tapered roller shaft Several receiving hoppers 5 suitable for receiving different steel ball sizes are successively installed on the upper side of the machine base 4 directly below the 6; When in use, when steel balls are poured into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com