Flexible AI vision full-automatic mask machine

A fully automatic, mask technology, applied in clothing, tools for sewing clothes, clothing, etc., can solve the problems that the mask production line does not have automatic quality inspection, cannot cope with the huge demand for masks, and the quality of masks is difficult to guarantee. Manual quality inspection link, conducive to large-scale promotion and application, high openness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

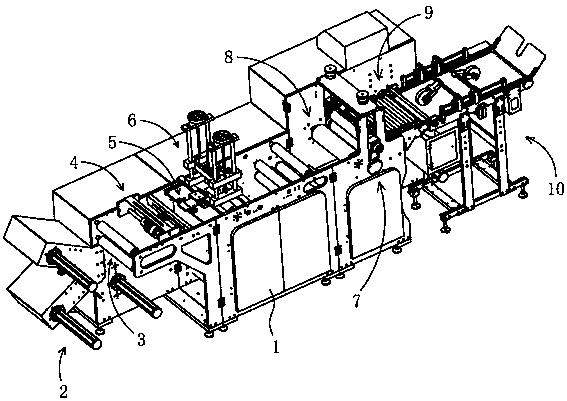

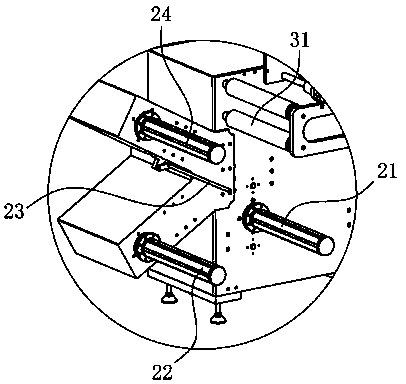

[0059] see figure 1 and figure 2 , as a specific embodiment of the flexible AI visual automatic mask machine provided by the present invention, the integration mechanism 3 includes an integration roller 31, and various raw materials are stacked together when passing the integration roller 31.

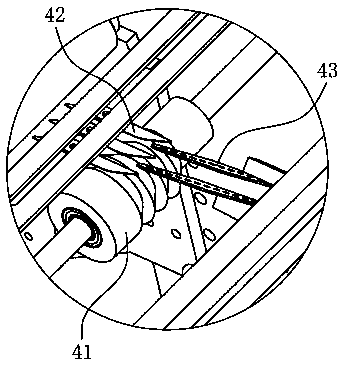

[0060] see figure 1 , image 3 and Figure 4 , as a specific embodiment of the flexible AI visual automatic mask machine provided by the present invention, the forming mechanism 4 includes a forming roller 41, an inserting plate 42 arranged above the forming roller 41, and a guide plate 43 arranged on the downstream side of the forming roller 41 The forming roller 41 is provided with at least two annular guide grooves 411 extending along its circumference, the number of the inserting plates 42 and the annular guide grooves 411 is equal, and each inserting plate 42 extends into each annular guide groove 411 correspondingly, each A gap 11 is formed between two adjacent inserting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com