Double-layer ring-shaped cross belt sorting mechanism based on network model control

A cross-belt sorting and grid model technology, applied in sorting, conveyor control devices, conveyors, etc., can solve the problems of trouble, commodity explosion, large floor space, etc., to improve sorting efficiency, automatic The effect of sorting guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions in the embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

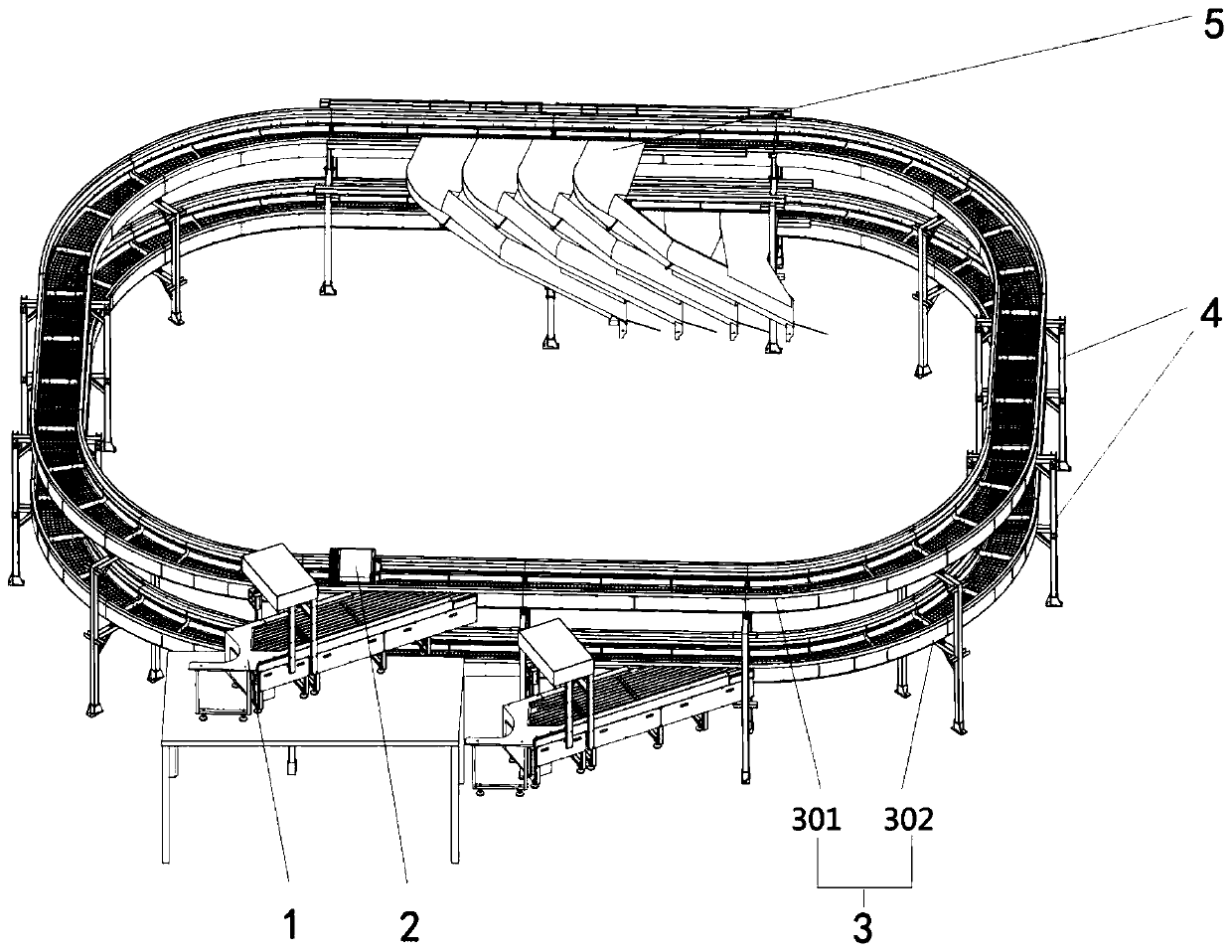

[0036] Such as Figure 1-9 As shown, the double-layer circular cross-belt sorting mechanism based on the grid model control includes a bag-up mechanism 1, a sorting trolley 2, a track device 3, a gantry 4 and a sorting outlet device 5, and the bag-up mechanism 1 The hypotenuse is connected with the outer wall of the track device 3, the sorting trolley 2 moves at a constant speed in the track device 3, the gantry 4 connects two mutually independent upper circular tracks 301 and the lower circular track 302 in the track device 3, and the sorting outlet device 5 is connected with the inner wall of track device 3.

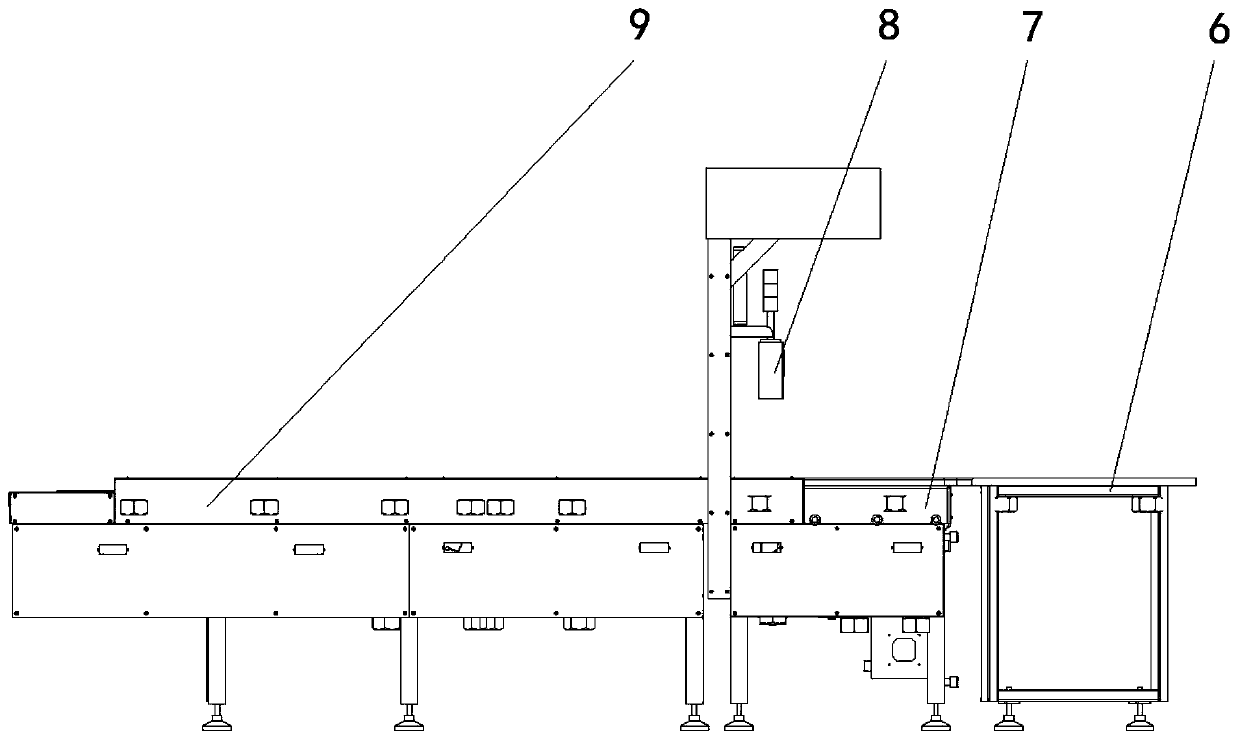

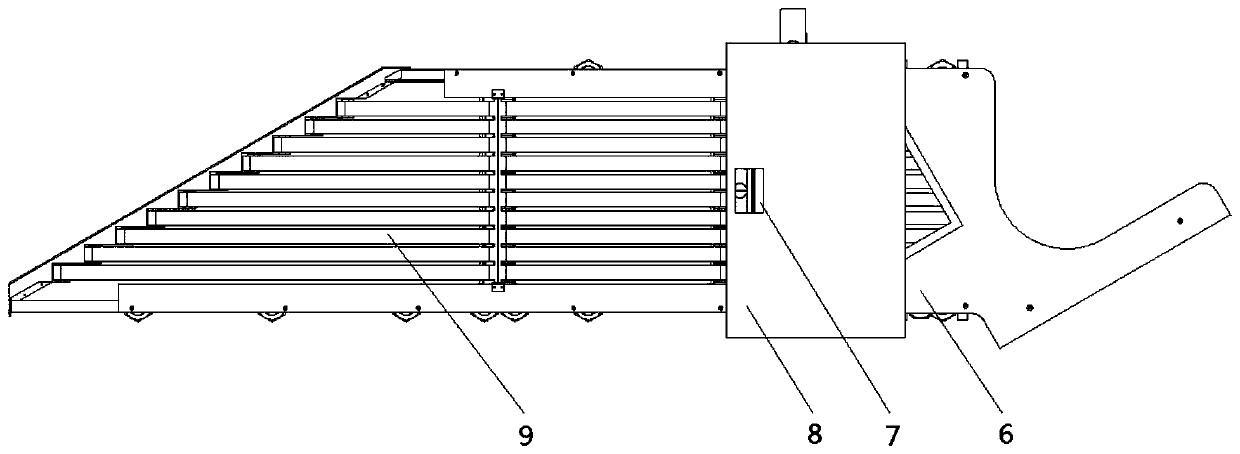

[0037] The bag-up mechanism 1 is composed of a bag-up operation platform 6 , a weighing sensor device 7 , a barcode recognition device 8 and a conveyor belt 9 . The loading operation table 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com