Lens film thickness automatic detection system

An automatic detection and film thickness technology, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of complex principles, slow speed, and high cost, and achieve the effects of improving detection efficiency, reducing damage, and improving grasping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

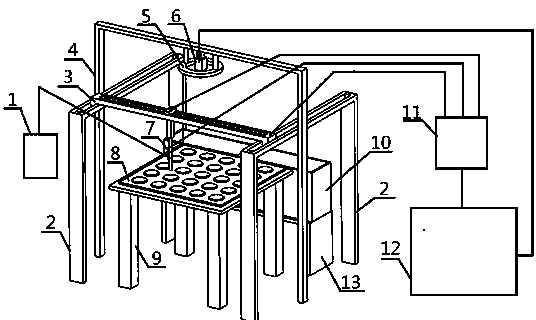

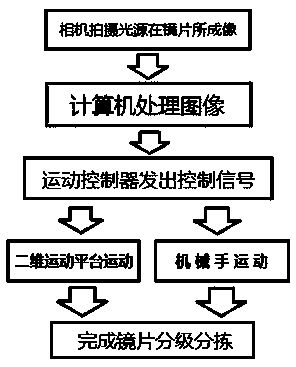

[0022] Such as figure 1 As shown, the lens film thickness automatic detection device system proposed by the present invention includes: an air pump 1, a two-dimensional motion platform support 2, a two-dimensional motion platform 3, a camera support 4, a light source 5, a camera 6, a suction cup manipulator 7, a lens tray 8, The lens tray is placed on a platform 9 , a defective grade box 10 , a motion controller 11 , a computer 12 and a defective grade box support 13 . It is characterized in that: the lens is placed on the lens tray 8, the lens tray 8 is placed on the lens tray placement platform 9, the two-dimensional motion platform 3 is installed on the two-dimensional motion platform bracket 2, and the suction cup manipulator 7 is installed on the two-dimensional motion platform 3, The camera 6 and the light source 5 are installed on the camera bracket, the defective-grade box bracket 13 is placed close to the lens tray placement platform 9, the defective-grade box 10 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com