Automatic cap welding machine of smoke pipe

An automatic welding and smoke pipe technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding efficiency, high degree of automation, cumbersome welding cap operation, etc., to improve processing efficiency, high degree of automation, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings:

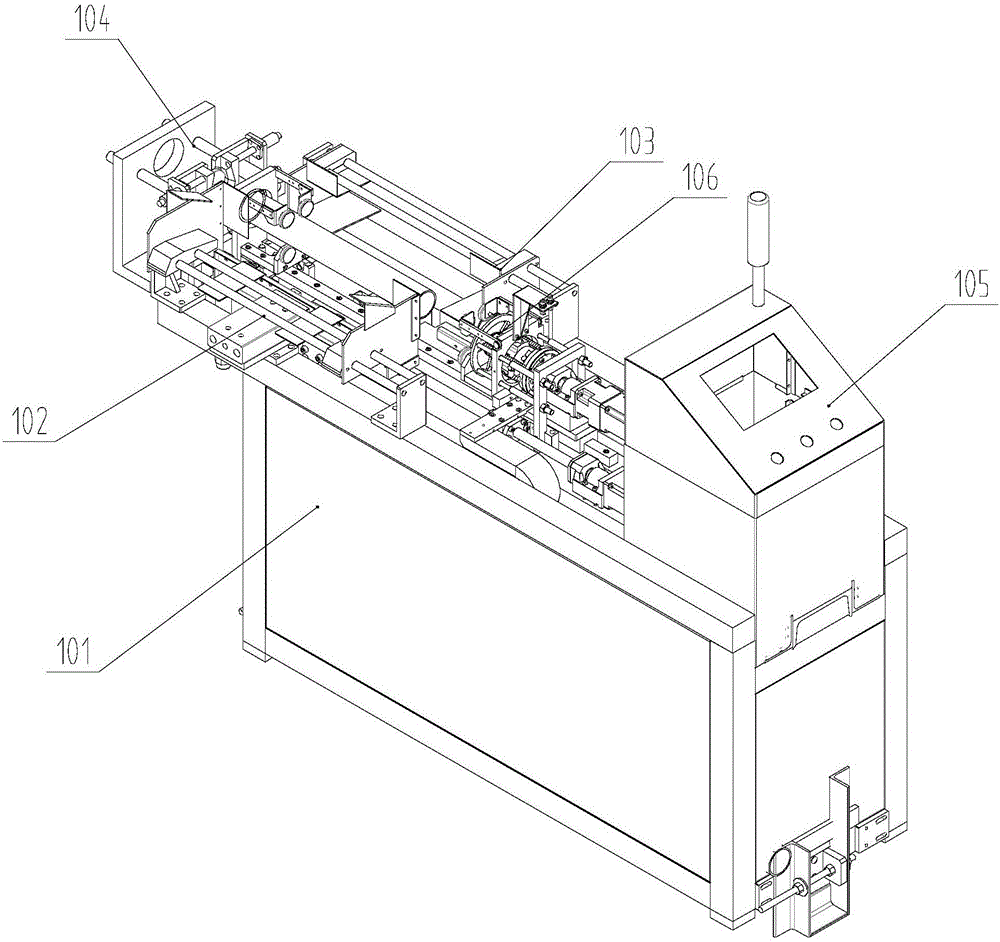

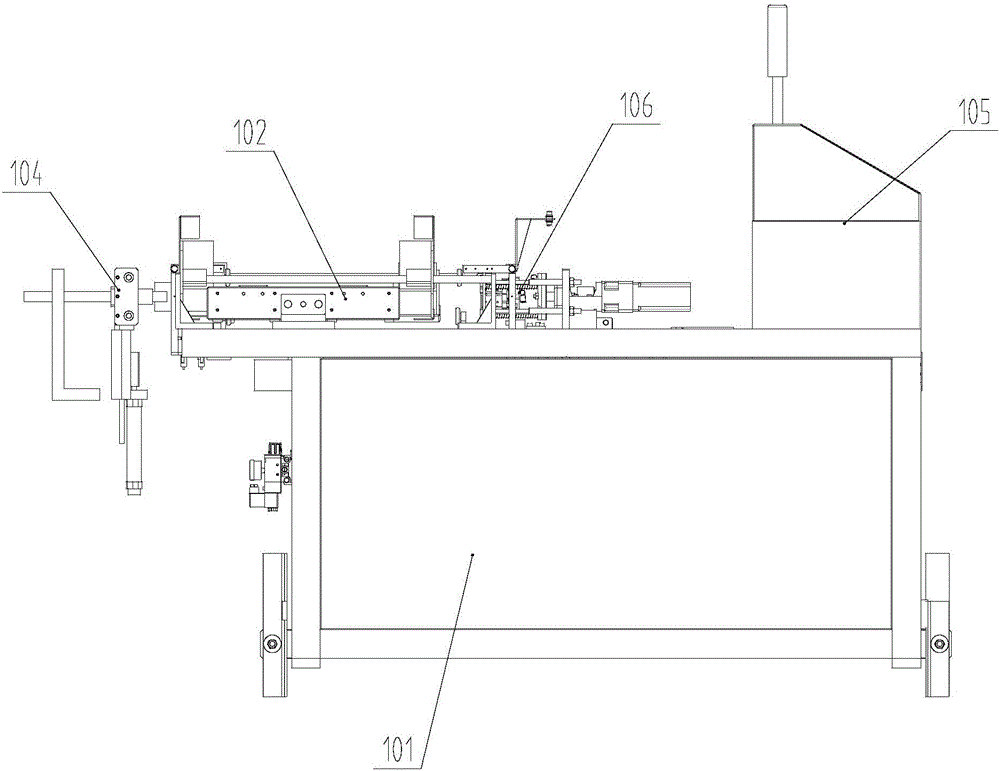

[0042] like Figures 1 to 8 As shown, an automatic cap welding machine for smoke pipes includes a frame body 101, a pushing module 102, a blanking module 103, a welding cap module 104, a console 105 and a clamping feeding module 106. The welding cap module 104 is provided with On the left side of the frame body 101, the welding cap module 104 is used to fix the position of the round cap; 106 is fixed on the frame body 101, the pushing module 102 and the unloading module 103 are respectively arranged on the frame body 101 on both sides of the clamping and feeding module 106, and the console 105 is fixed on the frame The main body 101 is used to control the movement of the pushing module 102 and the clamping and feeding module 106 .

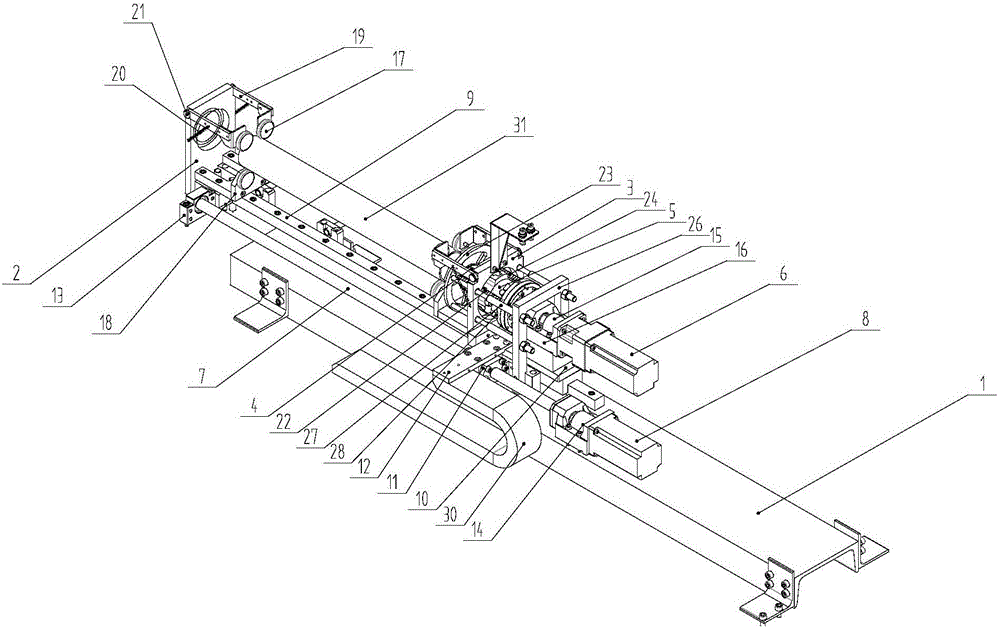

[0043] The clamping and feeding module 106 includes a first arch 2 , a second arch 3 , a three-jaw chuck 4 , a chuck driving cylinder 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com