Small product batch feeding device and implementation method thereof

A product and equipment technology, applied in the field of small product batch feeding equipment, can solve the problem of low feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

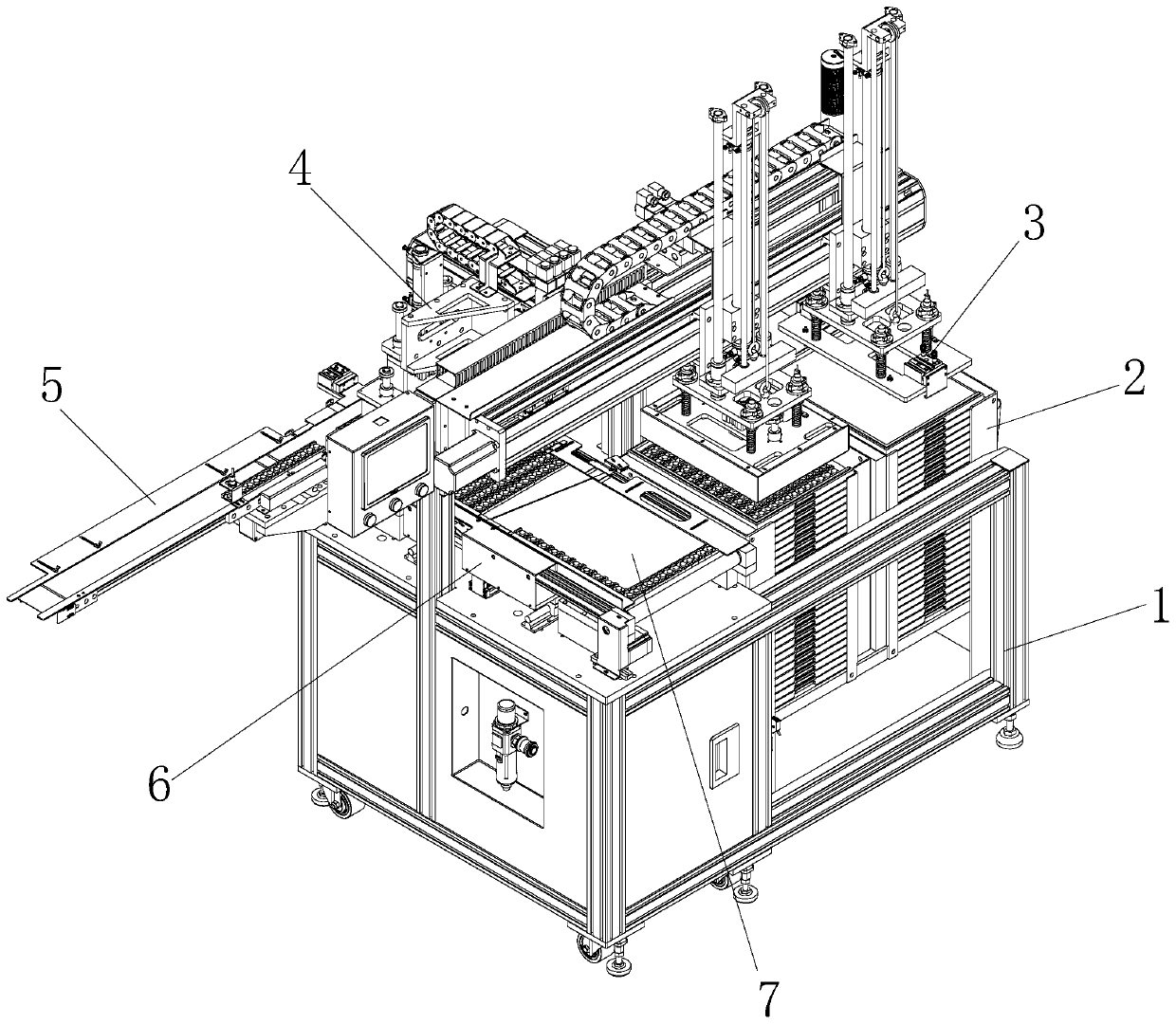

[0043] see Figure 1-15 , the present invention provides the following technical solutions: a batch feeding device for small products, including a workbench 1, a tray storage mechanism 2 is placed inside the workbench 1, and the two sides of the tray storage mechanism 2 above the workbench 1 are respectively connected with Magnetic suction feeding mechanism 3 and transition device 7, one side of transition device 7 is provided with adjustment mechanism 6, one end of transition device 7 is provided with magnetic suction transplanting mechanism 4, and one side of magnetic suction transplanting mechanism 4 is provided with discharging Agency 5.

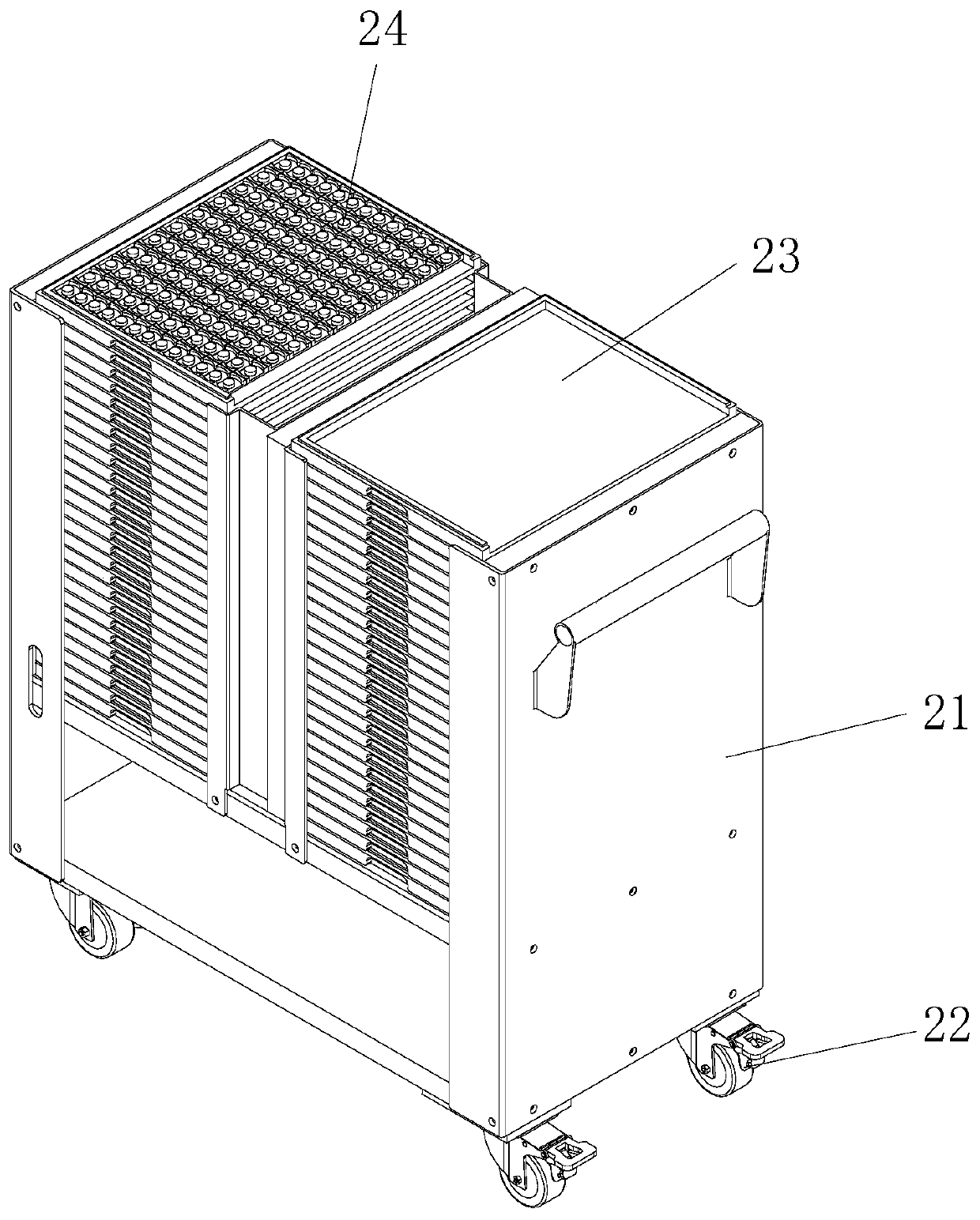

[0044]Further, the tray storage mechanism 2 includes a storage rack 21, the four corners of the bottom of the storage rack 21 are respectively connected with casters 22, the inside of the storage rack 21 is respectively provided with an empty tray station 23 and a full tray station 24, and the empty tray Station 23 is located on one sid...

Embodiment 2

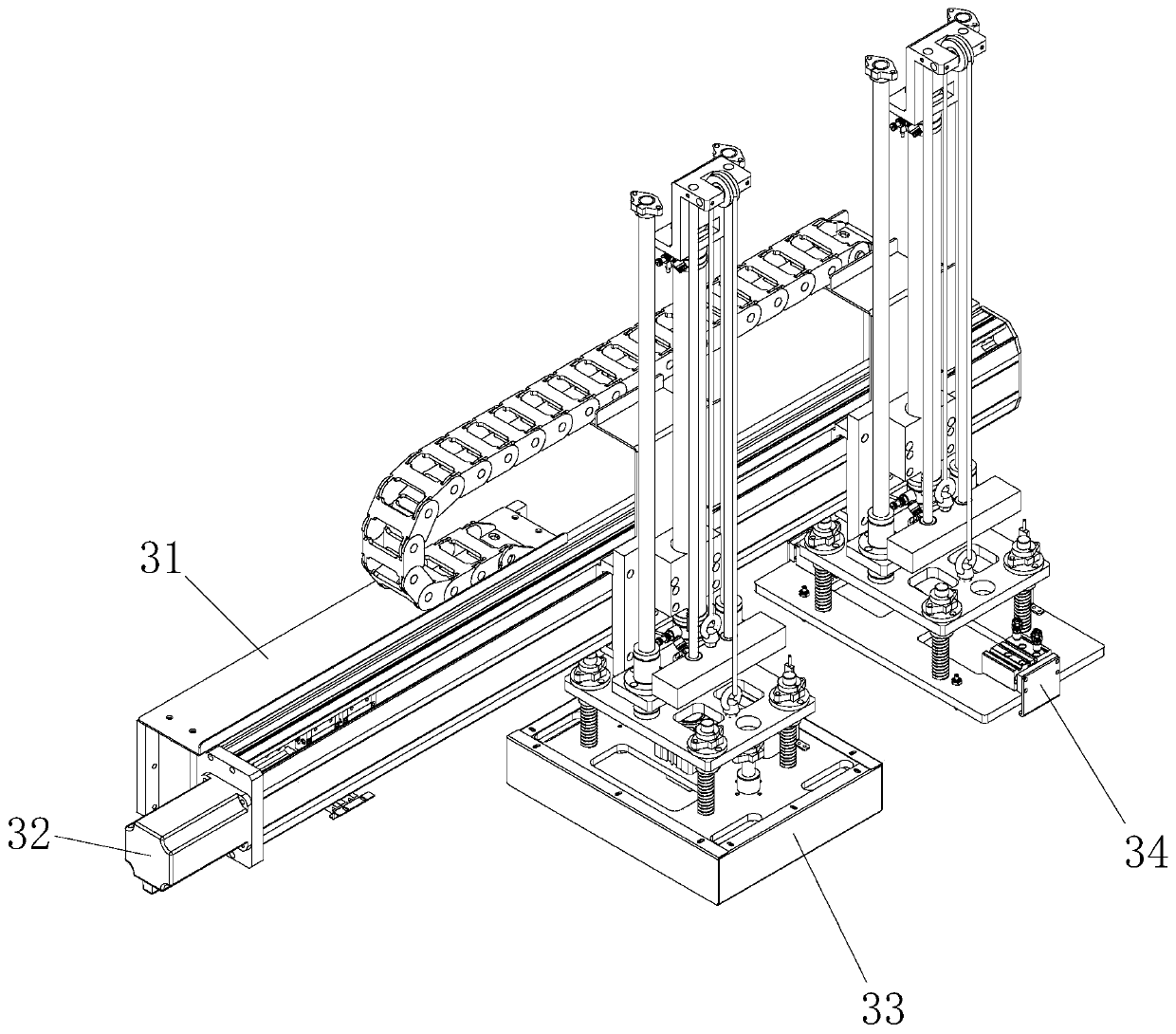

[0067] The difference between this embodiment and Embodiment 1 is that further, the loading and unloading mechanism 33 includes a lifting mechanism 8, a buffer mechanism 9 and a magnetic suction mechanism 35, wherein the lifting mechanism 8 is installed on the linear module 31 of the magnetic suction feeding mechanism. On the slider, the bottom of the lifting mechanism 8 is connected with a buffer mechanism 9, and the bottom of the buffer mechanism 9 is connected with a magnetic suction mechanism 35. The empty tray mechanism 34 includes a lifting mechanism 8, a buffer mechanism 9 and a splint mechanism 36. The lifting mechanism 8 is installed on the On the slider of the linear module 31 of the magnetic suction feeding mechanism, a buffer mechanism 9 is connected below the lifting mechanism 8 , and a splint mechanism 36 is connected below the buffer mechanism 9 .

[0068]Further, the magnetic suction mechanism 35 includes a guard plate 351, a magnetic suction cylinder 352, a mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com