Beef processing equipment

A processing equipment, beef technology, applied in the direction of food science, etc., can solve the problems of increasing the workload of workers, moving the hammer plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

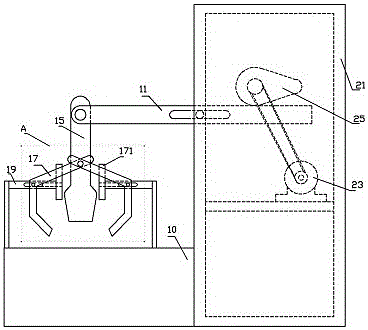

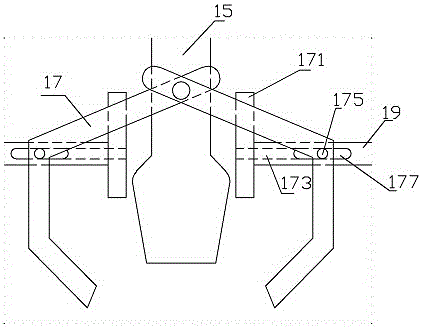

[0016] The reference signs in the drawings of the description include: workbench 10, connecting rod 11, hammer head 15, jaw 17, material storage cylinder 171, fence 173, hinge column 175, chute 177, cross bar 19, power chamber 21 , motor 23, cam 25.

[0017] Such as figure 1 The beef processing equipment shown includes a workbench 10, a power mechanism and a processing mechanism. The power mechanism includes a power chamber 21 positioned at one side of the workbench 10. A placement plate is arranged in the power chamber 21, and a motor 23 is installed on the placement plate; Cam 25 is hinged in chamber 21, and cam 25 is positioned at the top of motor 23, and motor 23 drives cam 25 to rotate through belt; 25 offset each other, and the right end of the railing is hinged with hammer head 15; figure 2 As shown, the lower end surface of the hammer head 15 is a plane, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com