Rotation type valve

A rotary and rotary valve technology, applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of people or objects collision, large space, damage, etc., to avoid collisions, ensure safety, and reduce damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

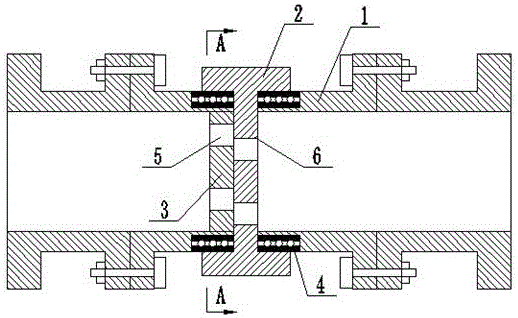

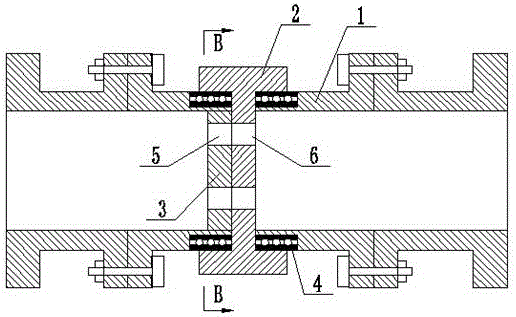

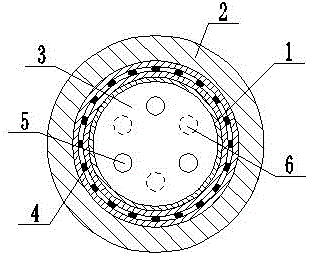

[0025] Such as Figure 1 to Figure 4 As shown, a rotary valve includes a pipeline 1, a rotary valve plate 2 and a fixed valve plate 3, the inner wall of the end of the pipeline 1 is connected with a fixed valve plate 3, and the fixed valve plate 3 is provided with a fixed orifice 5. The fixed orifice 5 is offset from the central axis position of the fixed valve plate 3, and the outer end of the pipe 1 is fitted with an annular bearing 4, and the rotating valve plate 2 is installed on the annular bearing 4, and the rotating The valve plate 2 is provided with a rotating orifice 6 which is coaxial with the fixed orifice 5 and has the same diameter.

[0026] In practical application, the rotating valve plate 2 rotates relative to the fixed valve plate 3, so that the rotating orifice 6 and the fixed orifice 5 overlap or intersect to realize the closing and opening of the liquid in the valve. Most of the control components of this valve are set It is installed inside the valve, occ...

Embodiment 2

[0028] Such as Figure 1 to Figure 4 As shown, a rotary valve includes a pipeline 1, a rotary valve plate 2 and a fixed valve plate 3, the inner wall of the end of the pipeline 1 is connected with a fixed valve plate 3, and the fixed valve plate 3 is provided with a fixed orifice 5. The fixed orifice 5 is offset from the central axis position of the fixed valve plate 3, and the outer end of the pipe 1 is fitted with an annular bearing 4, and the rotating valve plate 2 is installed on the annular bearing 4, and the rotating The valve plate 2 is provided with a rotating orifice 6 which is coaxial with the fixed orifice 5 and has the same diameter.

[0029] The number of fixed orifices 5 is 3-5, and the number of rotating orifices 6 is the same as that of fixed orifices 5 .

[0030] The annular bearing 4 is made of nitrile rubber.

[0031] In practical application, the rotating valve plate 2 rotates relative to the fixed valve plate 3, so that the rotating orifice 6 and the fix...

Embodiment 3

[0035] Such as Figure 1 to Figure 4 As shown, a rotary valve includes a pipeline 1, a rotary valve plate 2 and a fixed valve plate 3, the inner wall of the end of the pipeline 1 is connected with a fixed valve plate 3, and the fixed valve plate 3 is provided with a fixed orifice 5. The fixed orifice 5 is offset from the central axis position of the fixed valve plate 3, and the outer end of the pipe 1 is fitted with an annular bearing 4, and the rotating valve plate 2 is installed on the annular bearing 4, and the rotating The valve plate 2 is provided with a rotating orifice 6 which is coaxial with the fixed orifice 5 and has the same diameter.

[0036] The number of fixed orifices 5 is 3-5, and the number of rotating orifices 6 is the same as that of fixed orifices 5 .

[0037] The annular bearing 4 is made of nitrile rubber.

[0038] The fixed valve plate 3 is threadedly connected with the pipeline 1 .

[0039] The rotary valve plate 2 is provided with a scale.

[0040]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com