Pinch roll mechanism

A technology of pinch rollers and racks, which is applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of wasteful cost and complicated structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

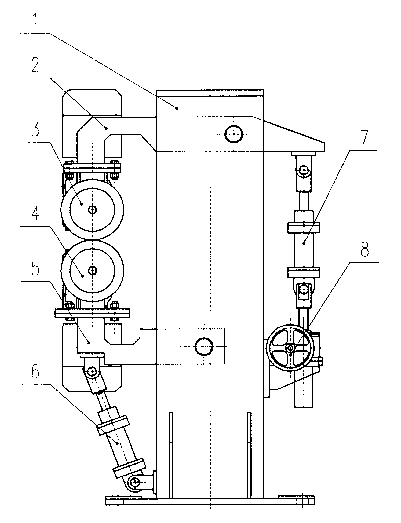

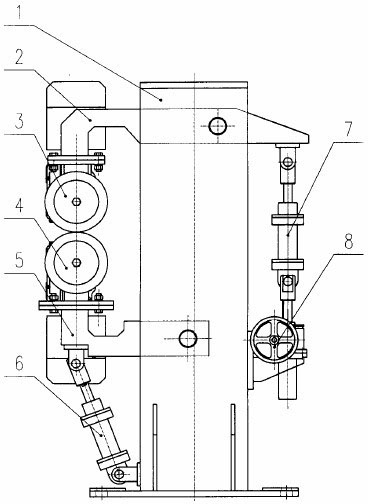

[0012] like figure 1 As shown, the lower hydraulic cylinder 6 and the elevator 8 are respectively installed at the bottom of both sides of the frame 1, the lower hydraulic cylinder 6 is hinged with the frame 1 through the bottom of the cylinder, and the elevator 8 is slidingly connected with the frame 1.

[0013] The lower swing rod 5 is L-shaped, one end of which is pinned to the lower part of the frame through a pin shaft, and the lower swing rod can rotate around this fixed point; The transmission device 4 is fixedly connected.

[0014] The upper swing link 2 is also L-shaped, and the length of its upper side is greater than the width of the frame 1. The long side of the upper swing link 2 is pinned to the upper part of the frame 1 through a pin shaft, and the upper swing link 2 can rotate around this fixed point; One end of the rod 2 is fixedly connected with the upper roller transmission device 3, the other end is hinged with the upper hydraulic cylinder 7, and the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com