Automatic production line from magnetic tile forming to kiln sintering and realizing method thereof

A technology for automated production lines and kilns, applied in mechanical conveyors, storage devices, conveyor objects, etc., can solve the problems of high labor intensity, low production efficiency, and low product qualification rate, and achieve high production efficiency and simple structure. , the effect of cheap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

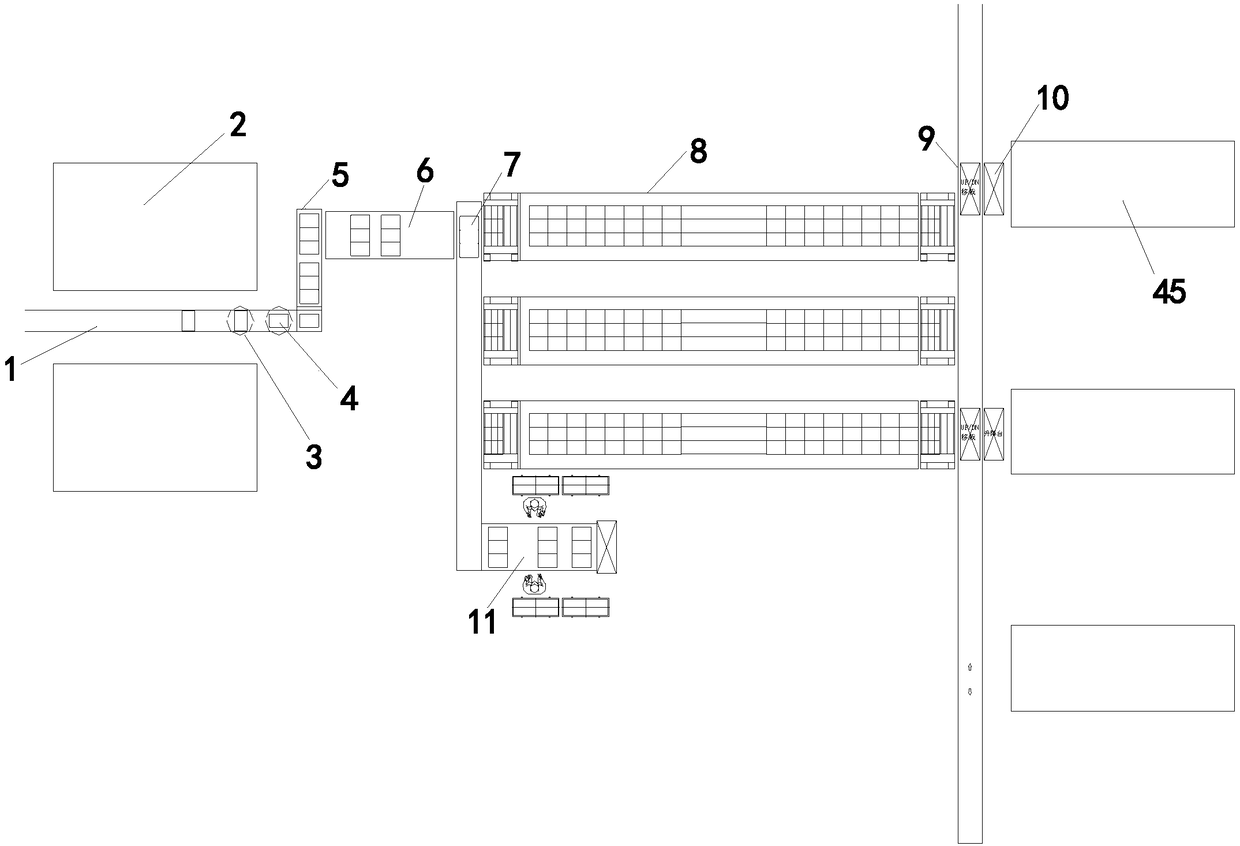

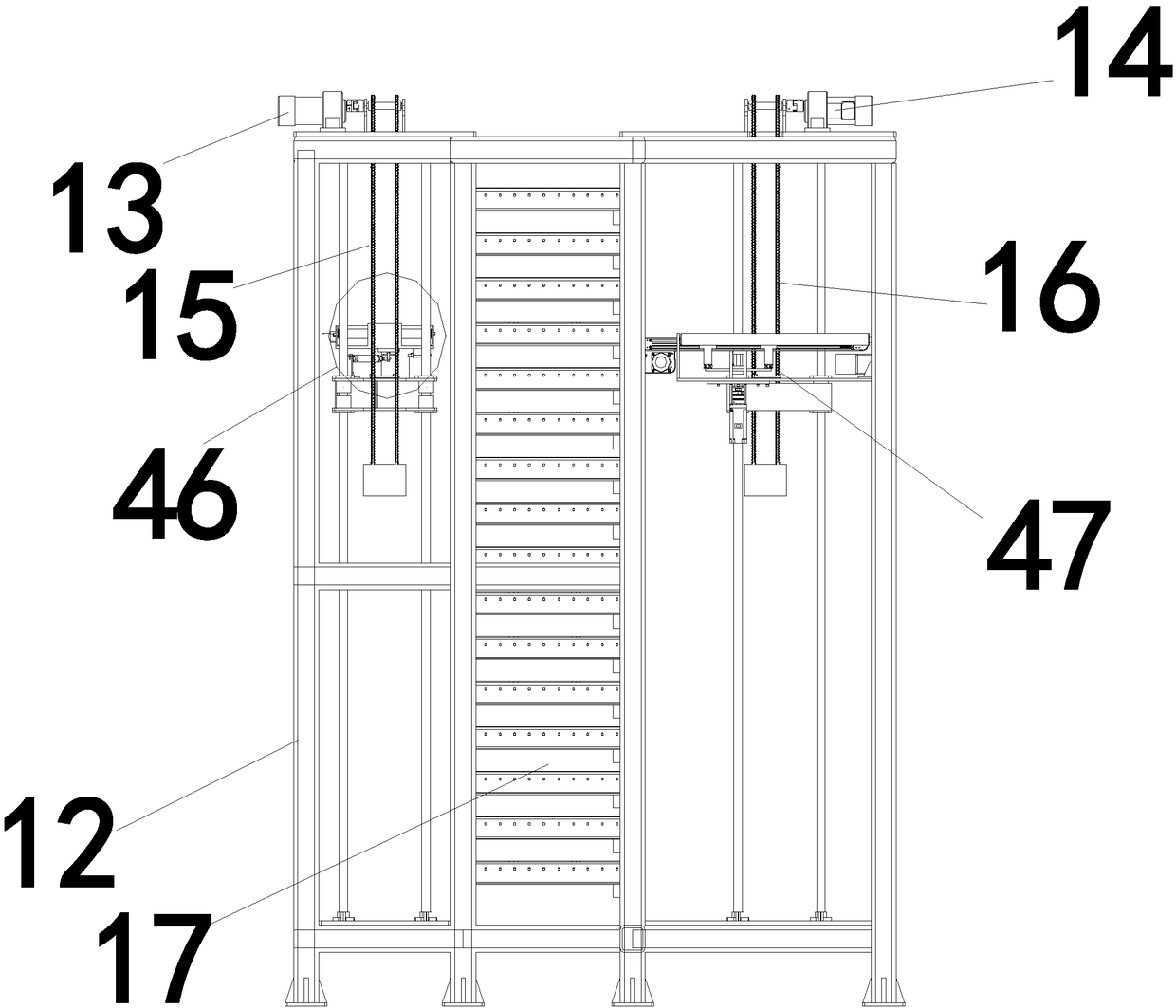

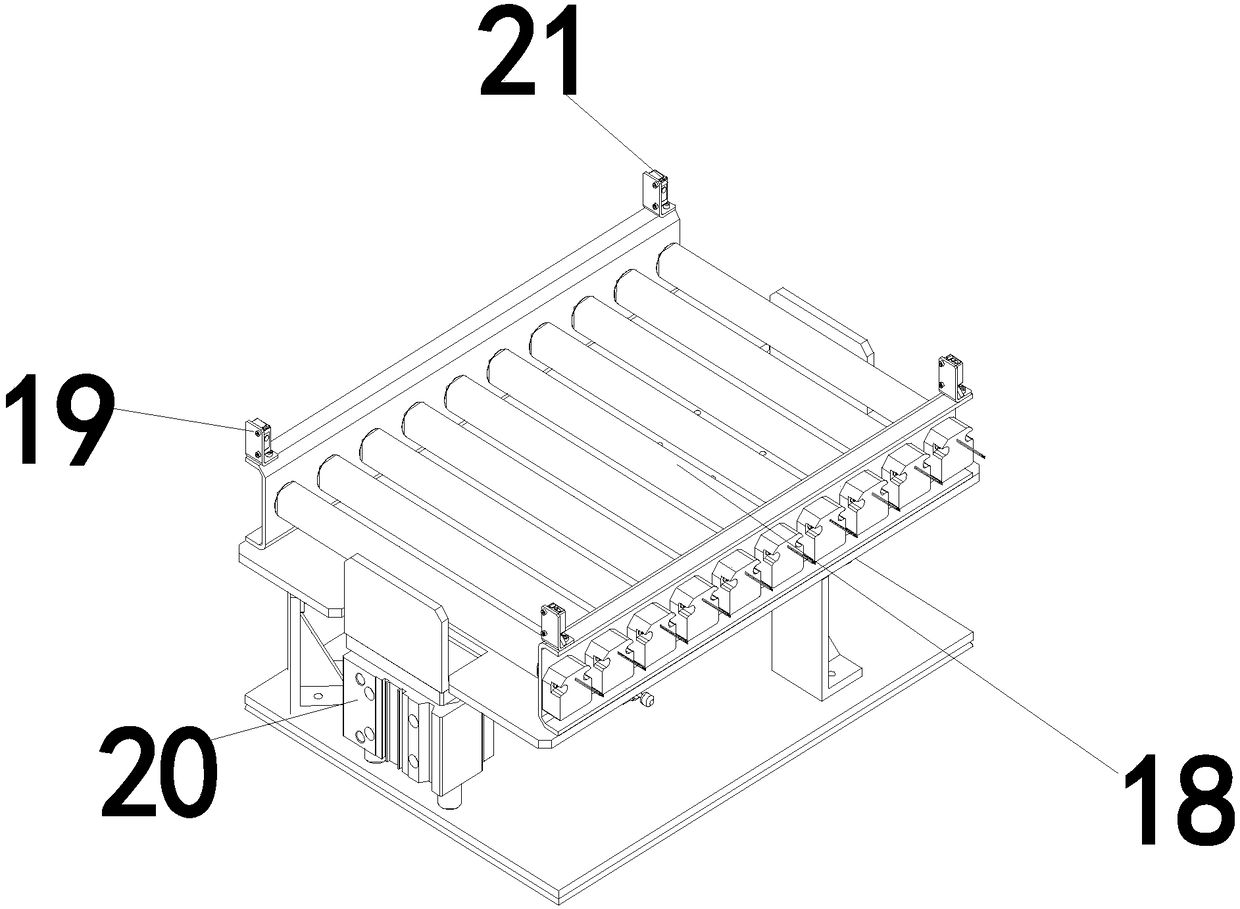

[0038] Such as Figure 1-8 As shown, an automatic production line from magnetic tile forming to kiln sintering includes a forming conveyor belt, a number of presses are installed on both sides of the forming conveyor belt, a recognition station is provided at the forward end of the forming conveyor belt, and a recognition station is set at the recognition station. There is an identification device, the front end of the identification station is equipped with a rotary station, and the side of the rotary station is equipped with a three-plate integrated warehouse. The outlet of the three-plate integrated warehouse is equipped with a three-plate transition conveyor belt. There are a number of intelligent warehouses on the side of the double-layer transfer conveyor vehicle, a warehouse double-layer conveyor belt is installed at the exit of the intelligent warehouse, and several docking lifting devices are installed on the side of the warehouse double-layer conveyor belt. A kiln is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com