Crank slow-down swinging feeding mechanism

A technology of feeding mechanism and crank, applied in the field of decelerating swing feeding mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

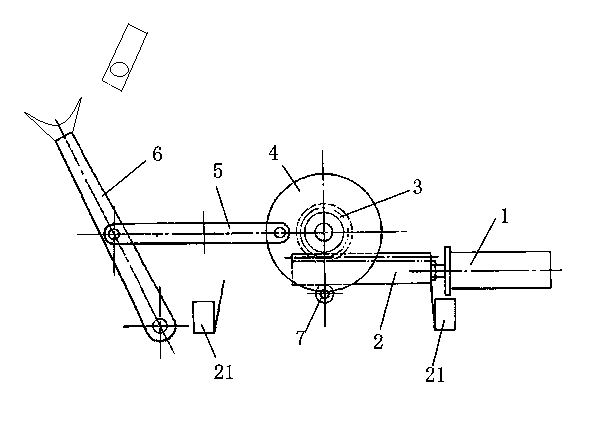

[0012] Such as figure 1 As shown, the crank deceleration swing feeding mechanism of the present invention includes a vertically placed bracket, and the bracket is provided with a cylinder 1, the piston rod of the cylinder 1 is fixedly connected to a rack 2, and the tooth surface of the rack 2 faces upward and engages There is a gear 3, a crank disc 4 is connected with a coaxial key on the gear 3, and a connecting rod 5 is hinged eccentrically on the crank disc 4, and the free end of the connecting rod 5 is hinged at the middle part of the rocker arm 6, The fixed end of the rocker arm 6 is hinged on the support. The above-mentioned cylinder 1, rack 2, gear 3, crank disc 4, connecting rod 5 and swing arm 6 are placed on the same side of the bracket, and the back of the rack 2 on the bracket is located directly below the gear and there is a pressing tooth Strip guide roller 7. There are also two blocks 21 that block the movement of the rack 2 on the support. A pressure sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com