Automatic sand conveying system

An automatic, sand conveying pipe technology, applied to conveyors, transportation and packaging, mixers, etc., can solve problems such as low degree of automation, proppant clogging, and incomplete sand discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

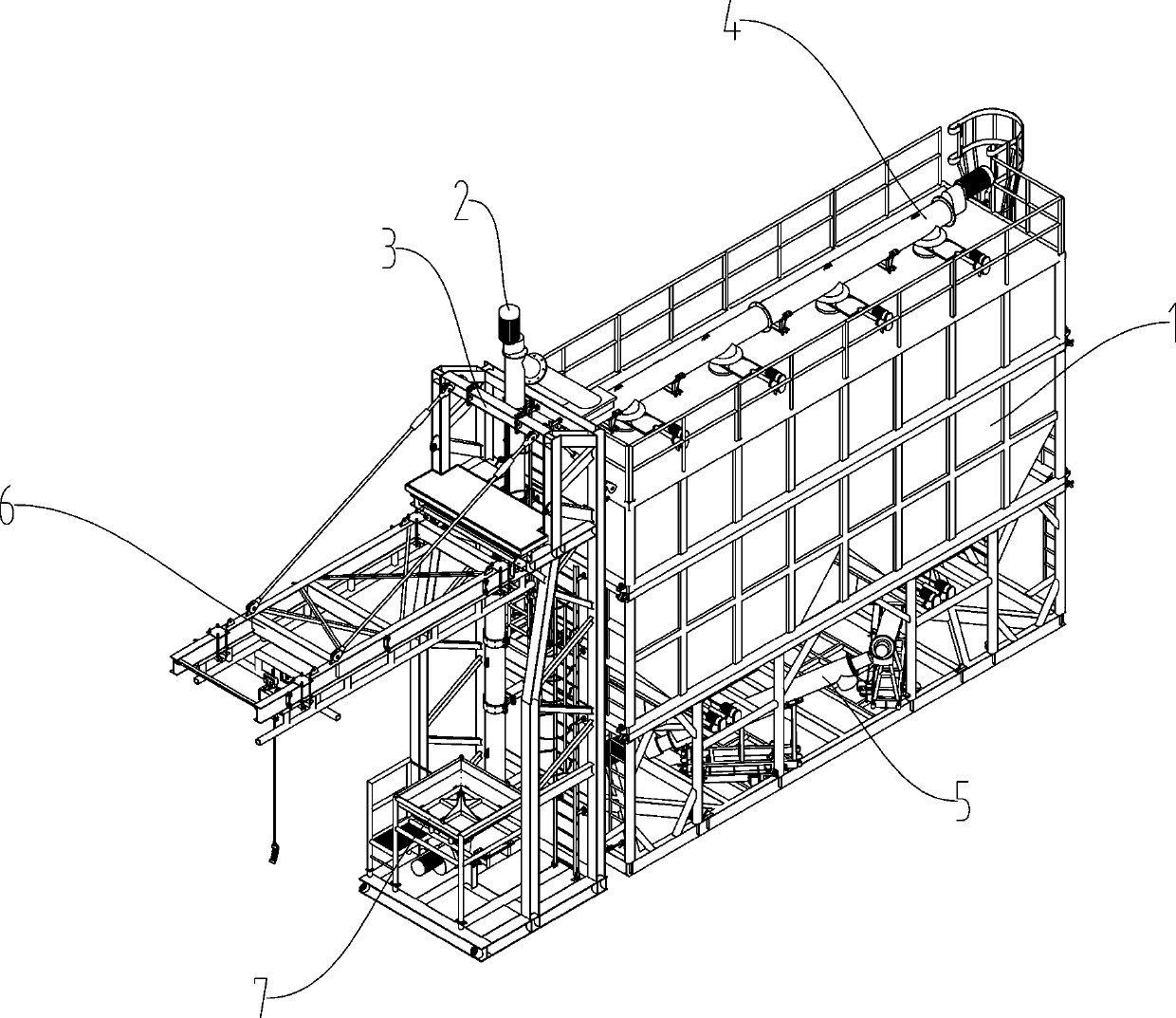

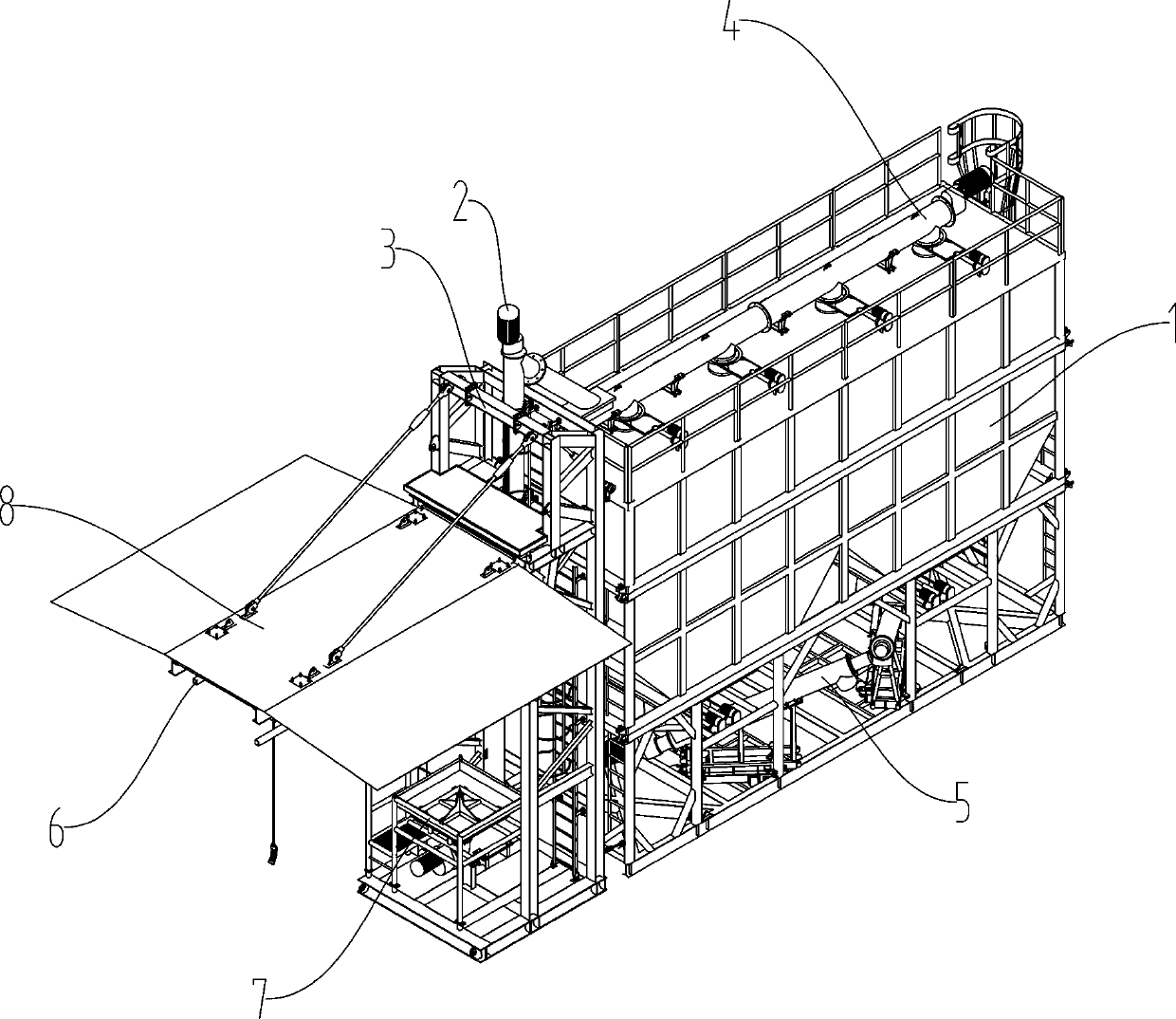

[0117] like figure 1 As shown, the automatic sand conveying system consists of sand storage device assembly 1, vertical spiral sand conveying assembly 2, mounting frame assembly 3, horizontal spiral sand conveying assembly 4, spiral sand discharging assembly 5, and sand bag lifting device 6 It is composed of the bag breaking device 7, the sand storage device assembly 1 is placed on a flat ground, the vertical screw sand conveying assembly 2 is fixedly connected with the mounting frame assembly 3, and the mounting frame assembly 3 is connected to the front end of the sand storage device assembly 1 Fixed connection, the horizontal screw sand conveying assembly 4 is fixedly connected to the top of the sand storage device assembly 1, the sand bag lifting device 6 is fixedly connected to the upper part of the mounting frame assembly 3, and the bag breaking device 7 is fixed to the bottom of the mounting frame assembly 3 connection, in other embodiments such as figure 2 As shown, ...

Embodiment 2

[0127] like figure 1 As shown, it is consistent with the description of Embodiment 1, and will not be repeated here.

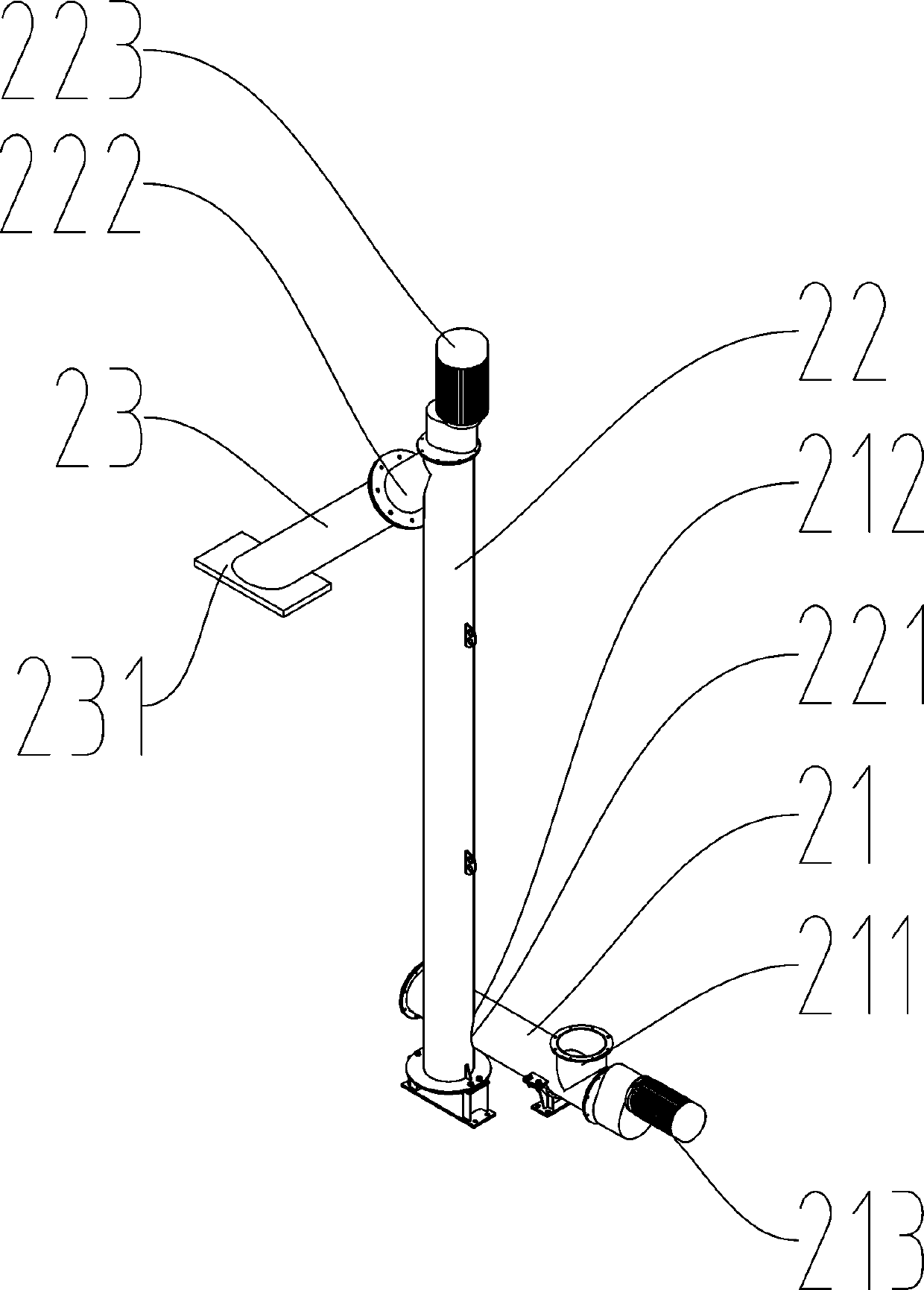

[0128] like image 3 As shown, it is consistent with the description of Embodiment 1, and will not be repeated here.

[0129] like Figure 5 As shown, it is consistent with the description of Embodiment 1, and will not be repeated here.

[0130] like Image 6 As shown, the horizontal spiral sand conveying assembly 4 includes a horizontal spiral sand conveying pipe 41, a horizontal spiral sand conveying pipe outlet 43 set at the bottom of the horizontal spiral sand conveying pipe 41, and a horizontal spiral sand conveying pipe 41 at the top of one end of the horizontal spiral sand conveying pipe 41. The feed port 42 of the spiral sand conveying pipe, the bracket 46 that fixes the horizontal spiral sand conveying pipe 41 on the top of the sand storage device assembly 1, and the driving motor 44 of the horizontal spiral sand conveying pipe fixedly connected t...

Embodiment 3

[0137] like figure 1 As shown, it is consistent with the description of Embodiment 1, and will not be repeated here.

[0138] like image 3 As shown, it is consistent with the description of Embodiment 1, and will not be repeated here.

[0139] like Figure 5 As shown, it is consistent with the description of Embodiment 1, and will not be repeated here.

[0140] like Image 6 As shown, the horizontal spiral sand conveying assembly 4 includes a horizontal spiral sand conveying pipe 41, a horizontal spiral sand conveying pipe outlet 43 set at the bottom of the horizontal spiral sand conveying pipe 41, and a horizontal spiral sand conveying pipe 41 at the top of one end of the horizontal spiral sand conveying pipe 41. The feed port 42 of the spiral sand conveying pipe, the bracket 46 that fixes the horizontal spiral sand conveying pipe 41 on the top of the sand storage device assembly 1, and the driving motor 44 of the horizontal spiral sand conveying pipe fixedly connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com