Full-automatic detection line for size of inner cavity of rotatory body

A dimension detection, fully automatic technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of the reliability discount of the detection results, the influence of the subjective factors of the testing personnel, and the self-heavyness of the product, so as to improve efficiency and reduce The effect of labor load and improvement of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

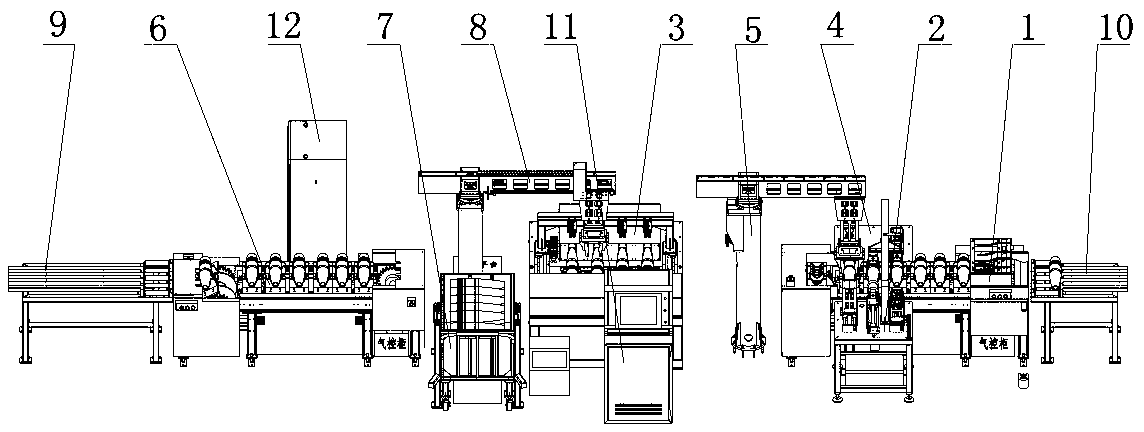

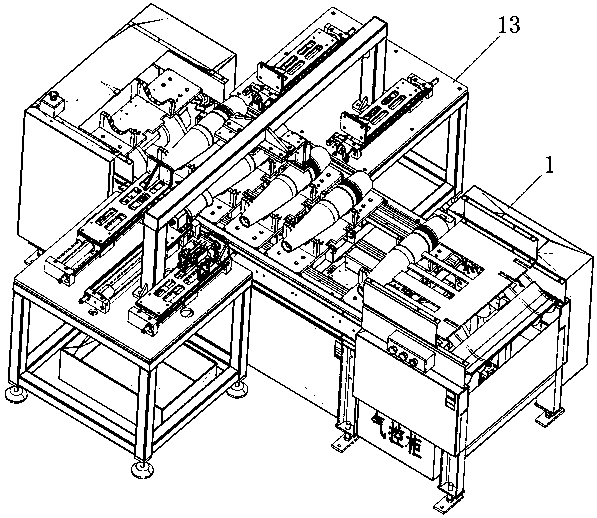

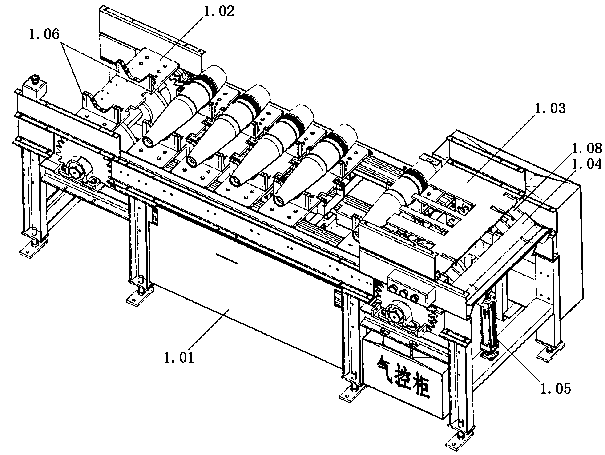

[0052] This embodiment provides a fully automatic detection line for the size of the inner cavity of the rotary, including a feeding conveyor line 1, a mouth and inner cavity cleaning device 2, and a size detection device 3;

[0053] The mouth and inner cavity cleaning device 2 includes an mouth cleaning assembly, a first radial pressing assembly, and an inner cavity cleaning assembly behind the mouth cleaning assembly; Brush unit and tail pressing unit; the cleaning brush unit is located on the side where the mouth of the rotating body to be tested is located, and includes a cleaning brush 2.01 for extending into the mouth of the rotating body to be tested and a first moving mechanism 2.02 that drives the cleaning brush 2.01 to move The tail pressing unit is located on the side where the tail of the rotating body to be tested is located, including a tail pressing plate 2.03 for pressing the tail of the rotating body to be tested and a second moving mechanism 2.04 that drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com