Patents

Literature

34 results about "Short foot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

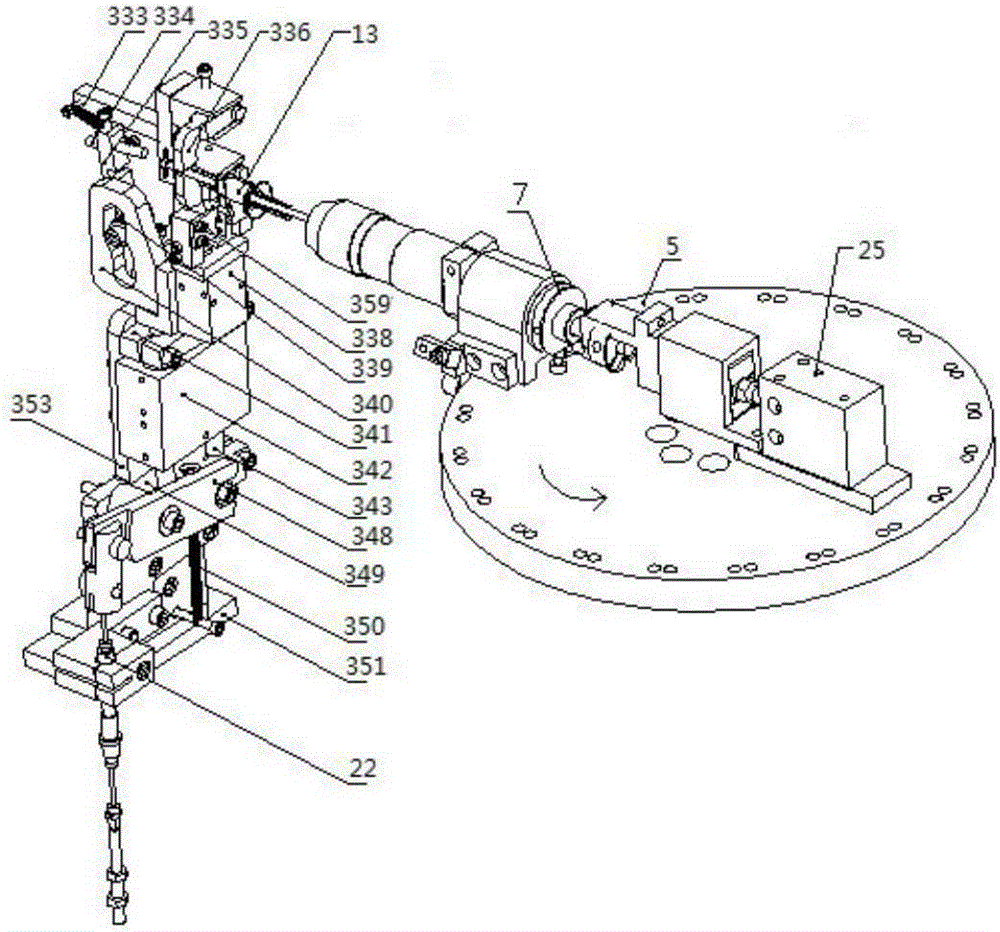

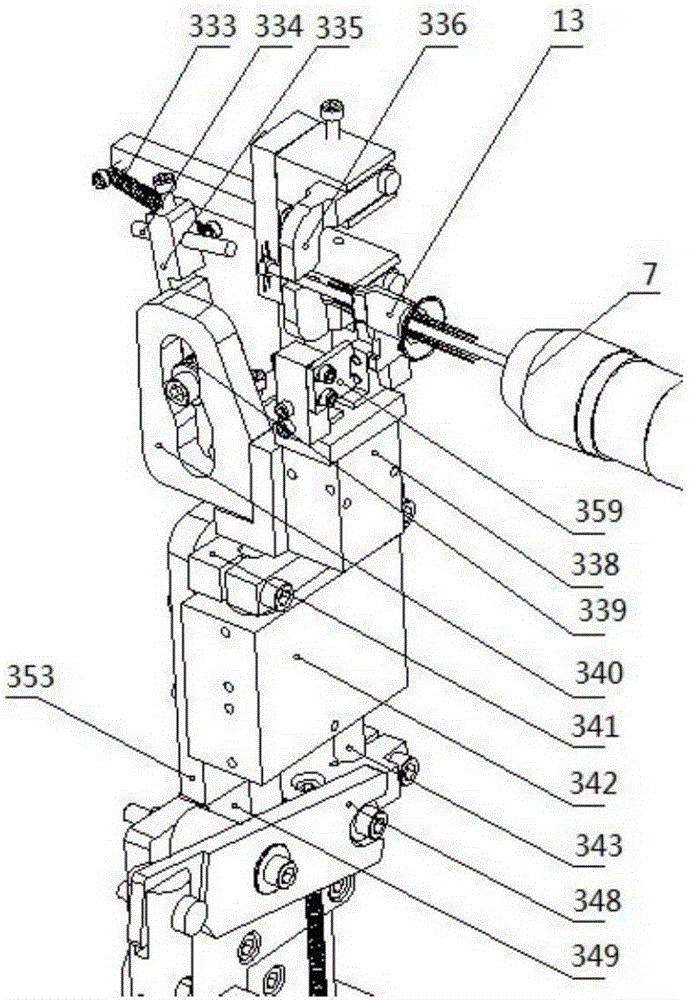

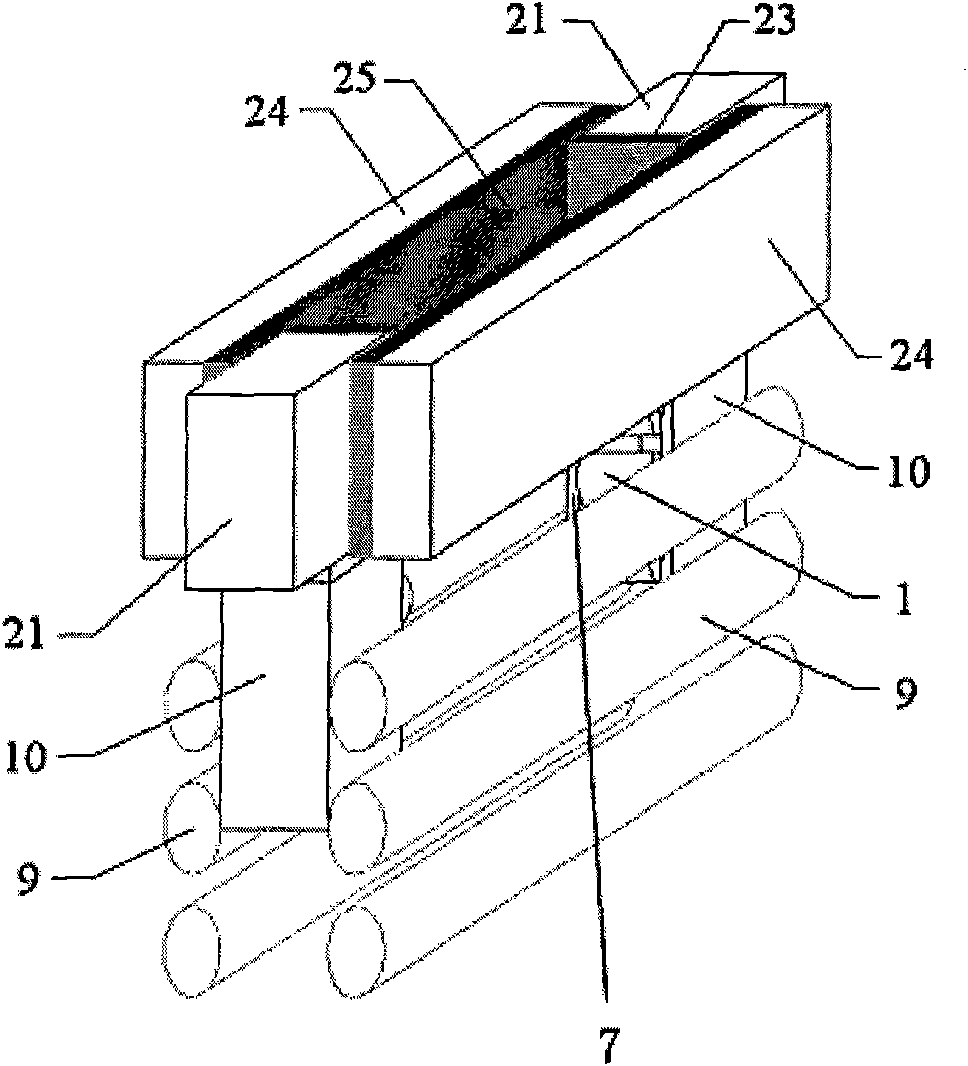

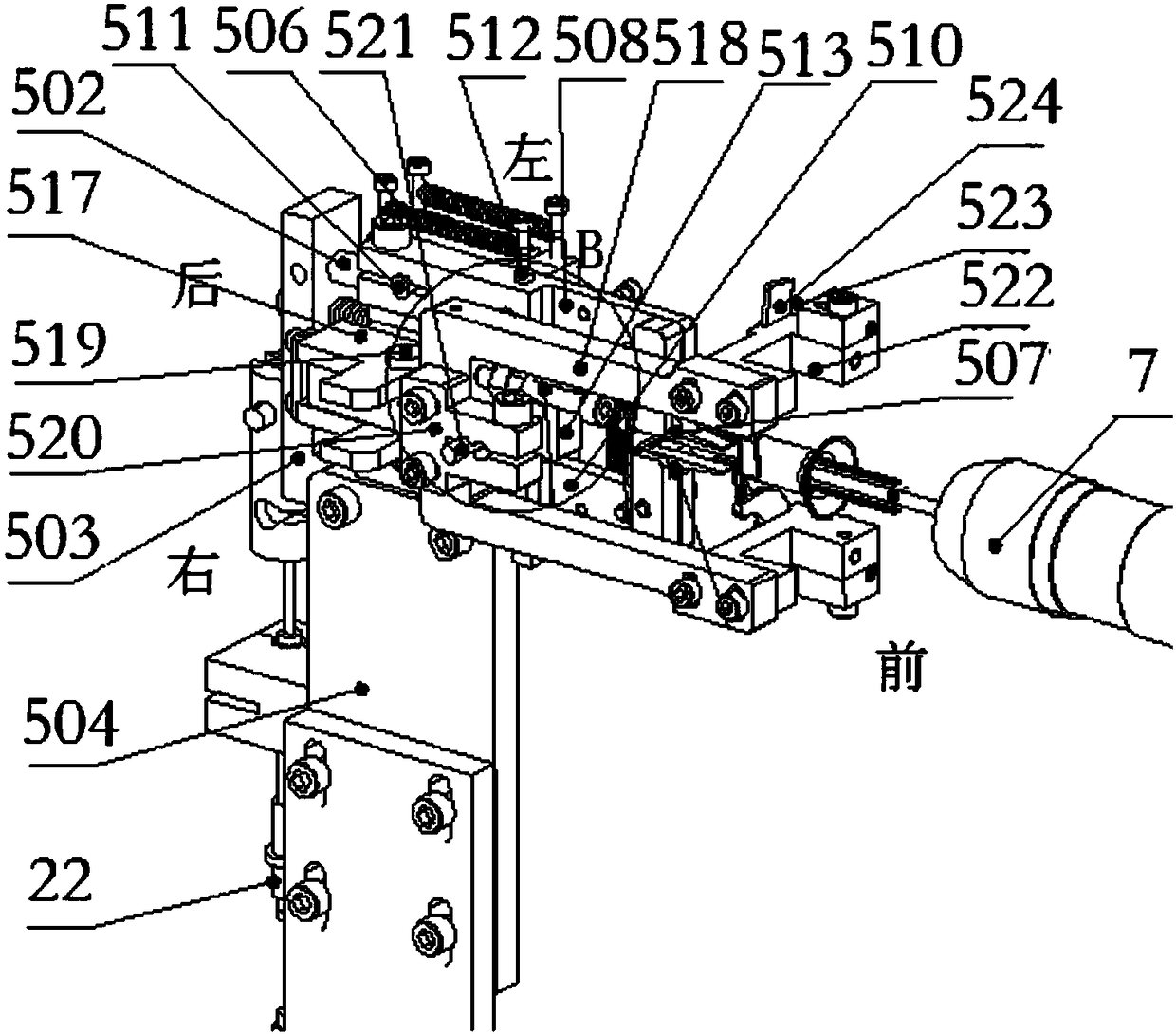

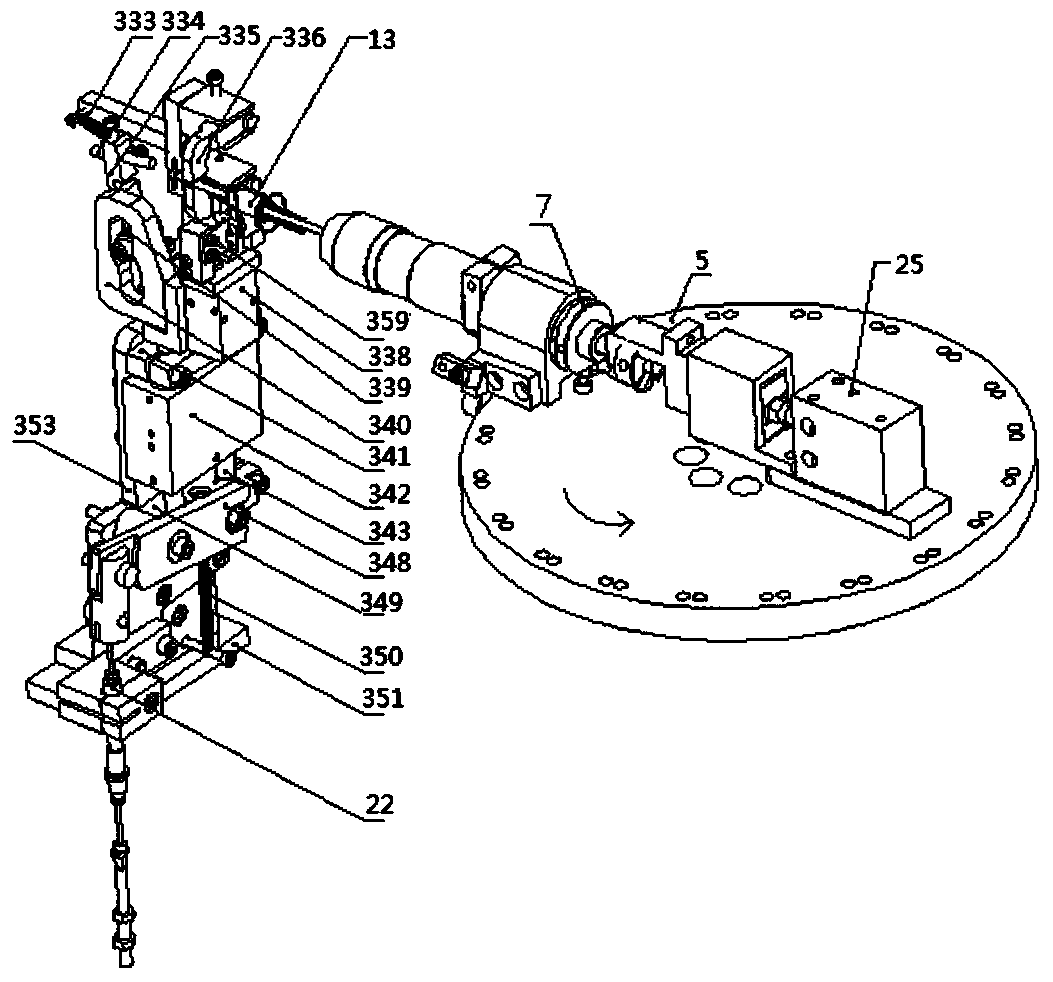

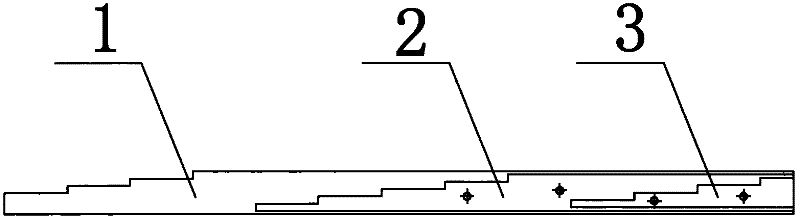

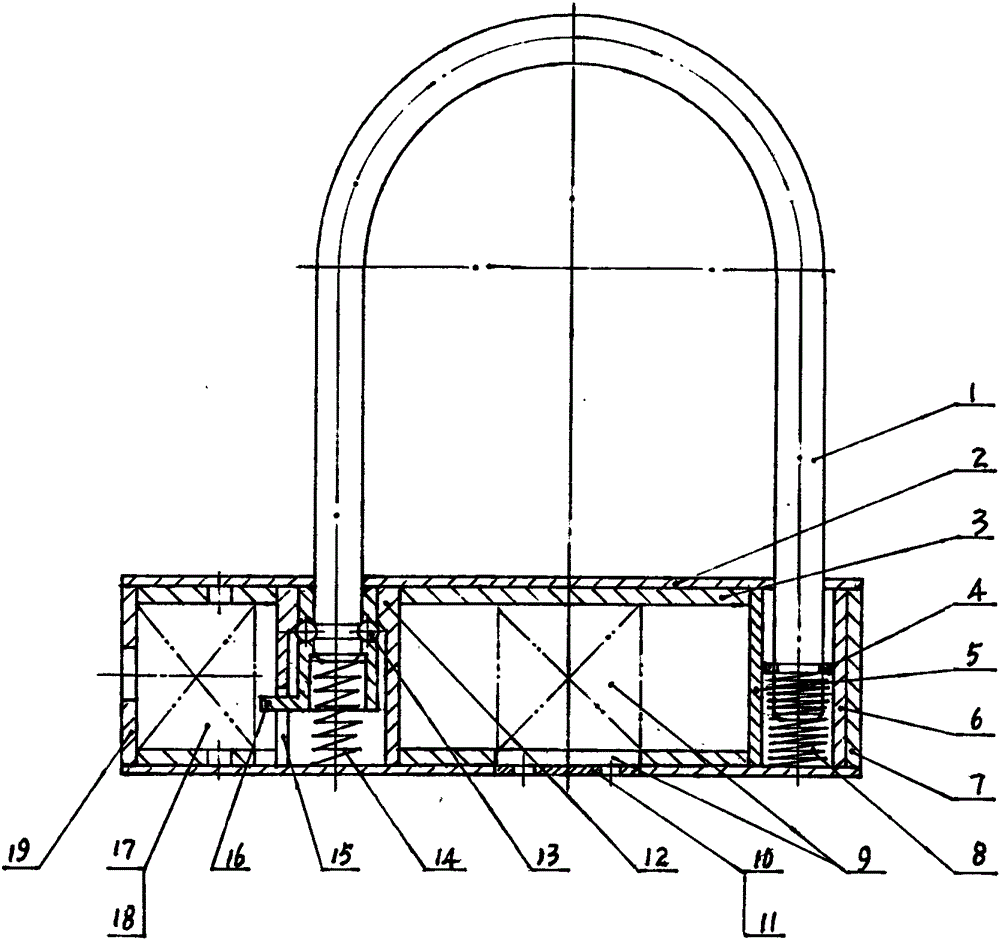

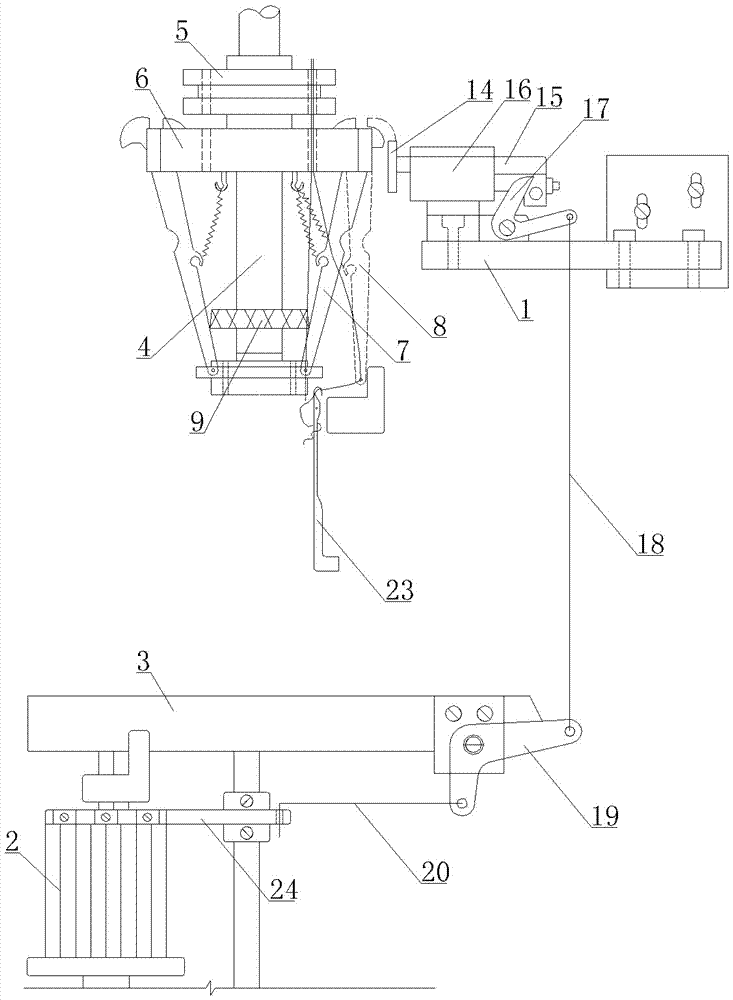

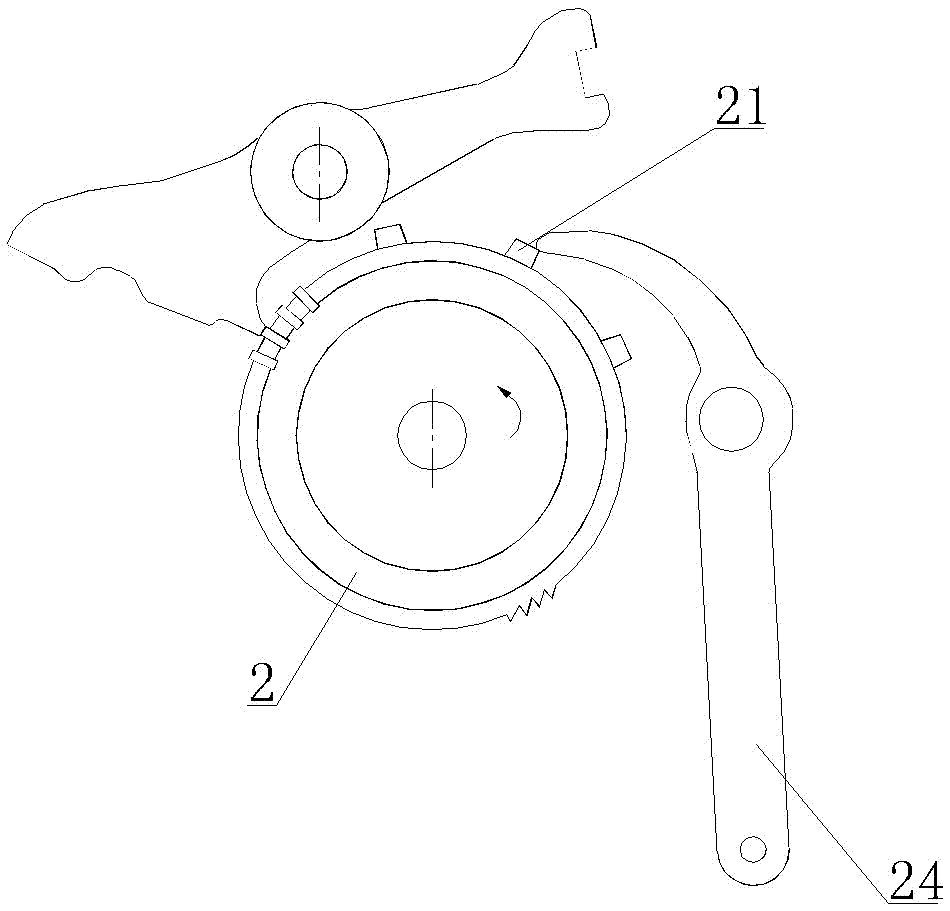

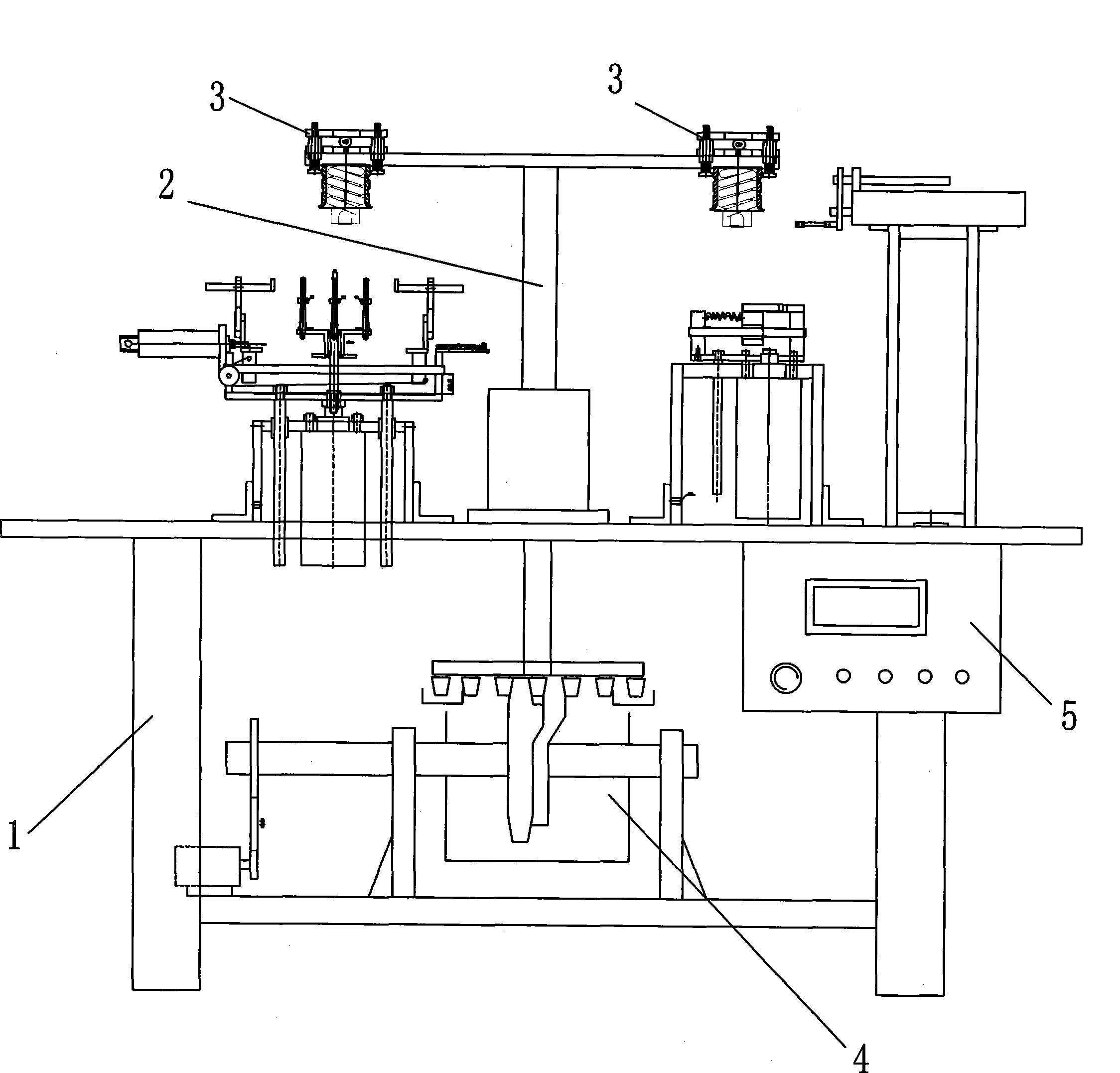

Full-automatic production equipment based on stem guide wire shaping and LED light strip welding integration

ActiveCN105345470AFacilitate automated processing operationsEasy to operateOther manufacturing equipments/toolsCircular discReduction drive

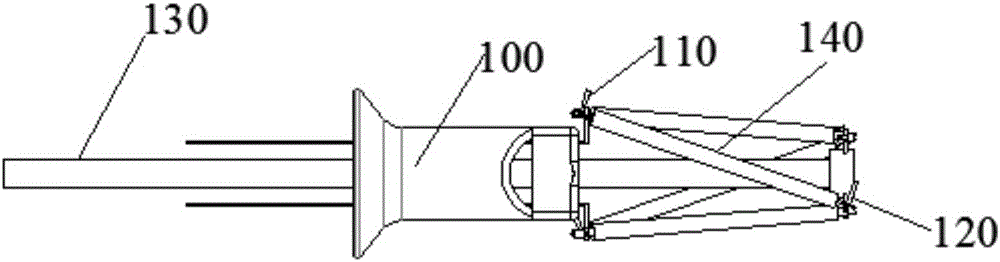

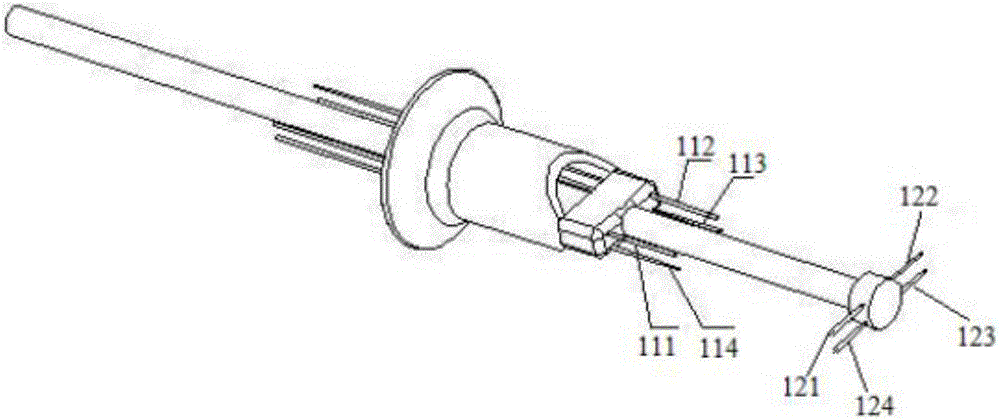

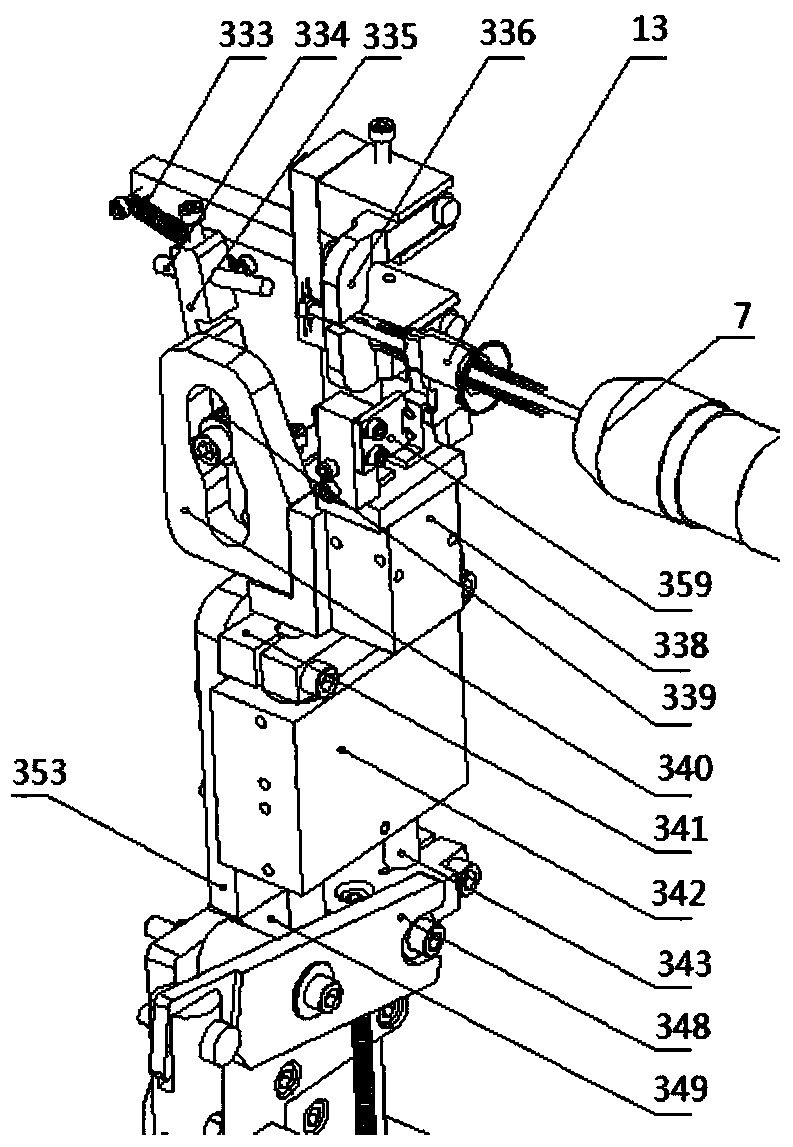

The invention discloses full-automatic production equipment based on stem guide wire shaping and LED light strip welding integration. The full-automatic production equipment comprises a main bottom plate, a platen and an upper bracket, wherein the upper end of the main bottom plate supports the platen through four thick bracket legs. A discharging mechanism and a buffering conveying mechanism are arranged on the left and the right of the side surface of the platen respectively, and a feed mechanism is arranged at the end of the buffering conveying mechanism. The platen is provided with a gap divider. An index plate rotates anticlockwise and is provided with a stem clamp. The main bottom plate is provided with a speed reducer, a station main shaft and a cam mechanism. A stem locating mechanism, a long foot arranging mechanism, a short foot poking mechanism, a 45-degree long foot poking assembly mechanism, a 45-degree short foot poking assembly mechanism, a foot straightening mechanism, an LED light strip shearing and conveying mechanism, an automatic LED light strip rotating and conveying mechanism and a welding mechanism are sequentially arranged on the platen from the front end of the feed mechanism and surround the index plate. The full-automatic production equipment is high in automation degree, high in welding and shaping efficiency and high in shaping accuracy.

Owner:南通睿博电器有限公司

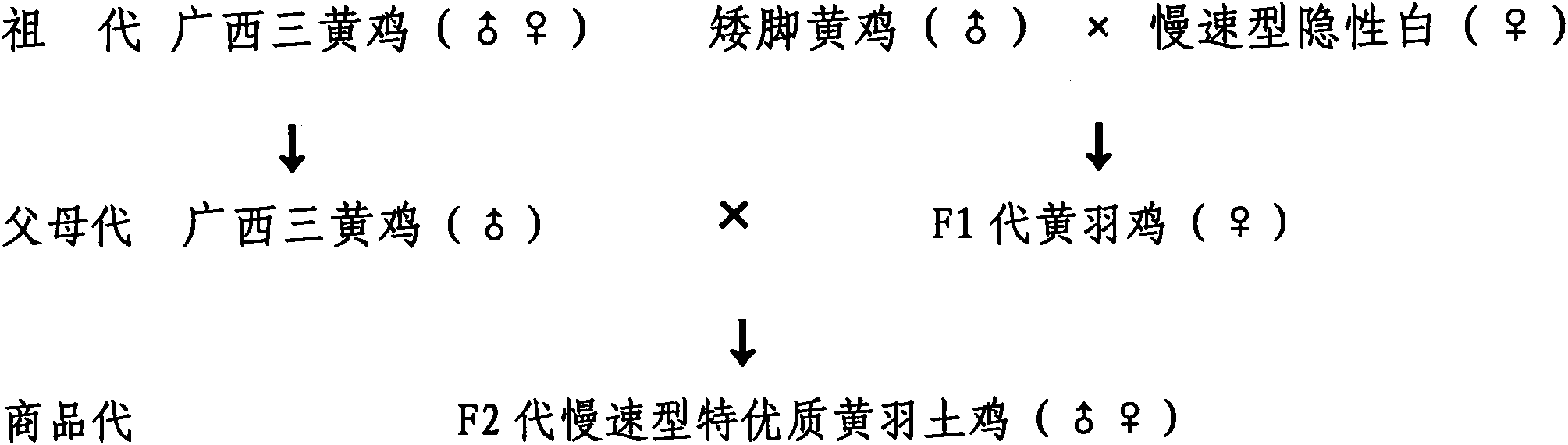

Breeding method of low-speed type extra-superior yellow-feather local chickens

The invention relates to the field of fowl breeding, in particular to the matching technical field of low-speed type extra-superior broiler chickens. The method relates to progenitor generations, parent generations and commodity generations. The method comprises the steps that as for the progenitor generations, cocks and hens of Guangxi sanhuang chickens are selected, and cocks of short-foot yellow chickens and hens of low-speed recessive white-feather chickens are selected for constituting first male lines and female lines; as for the parent generations, the cocks of the short-foot yellow chickens and the hens of the recessive white-feather chickens hybridize, and F1-generation yellow-feather chickens are obtained; as for the commodity generations, the cocks of the Guangxi sanhuang chickens and the hens of the F1-generation yellow-feather chickens hybridize, and the F2-generation slow-speed extra-superior yellow-feather local chickens are obtained. The yellow-feather local chickens bred in the method not only can keep body types and appearances of traditional yellow-feather local chickens, but also can keep taste of chicken and eggs, and production cost can be greatly reduced. Compared with the traditional yellow-feather local chickens, growth speed is increased by more than 30%, egg laying capacity of the parent generations is increased by more than 26%, the rate of survival is increased by more than 3.5%, the feed conversion ratio is reduced by more than 0.17%, and the defects that breeding hens have high brooding capacity and the low laying rate are overcome. In addition, the yellow-feather local chickens bred in the method has delicate meat quality and good mouth feel, breeding profits are increased, and further development of the low-speed type extra-superior chicken industry in China is promoted.

Owner:GUANGXI NANNING FUFENG AGRI & PASTORAL +1

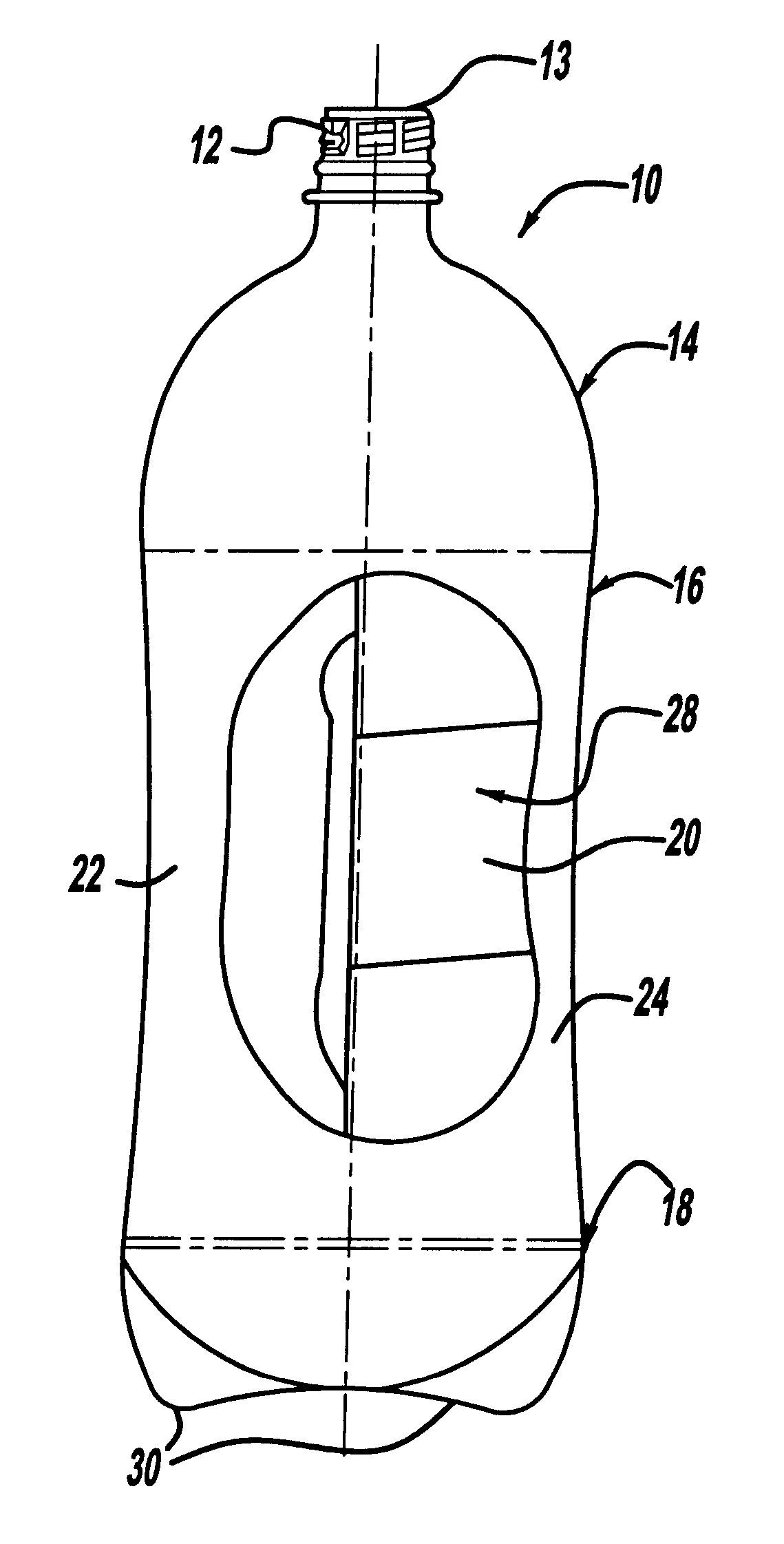

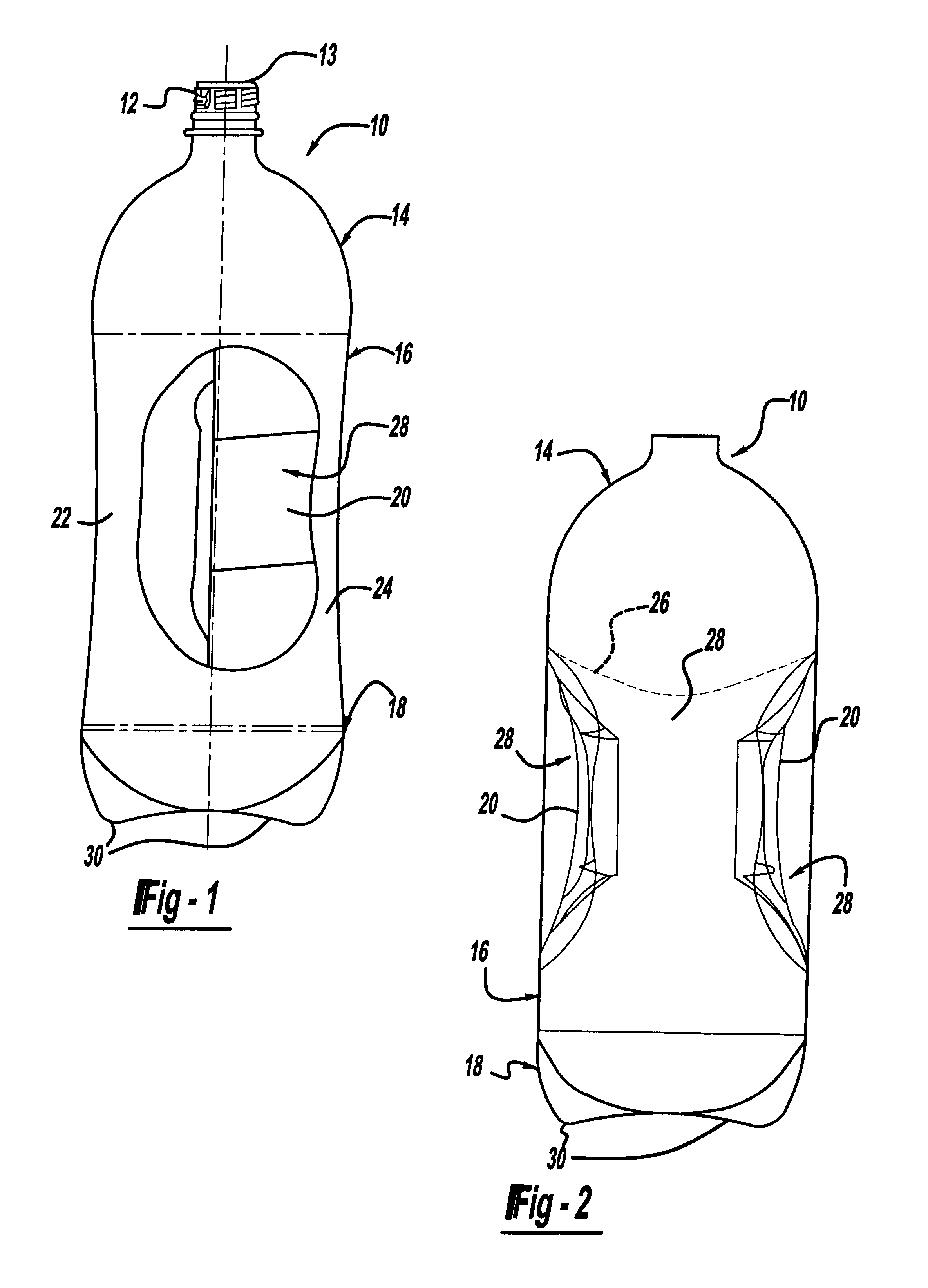

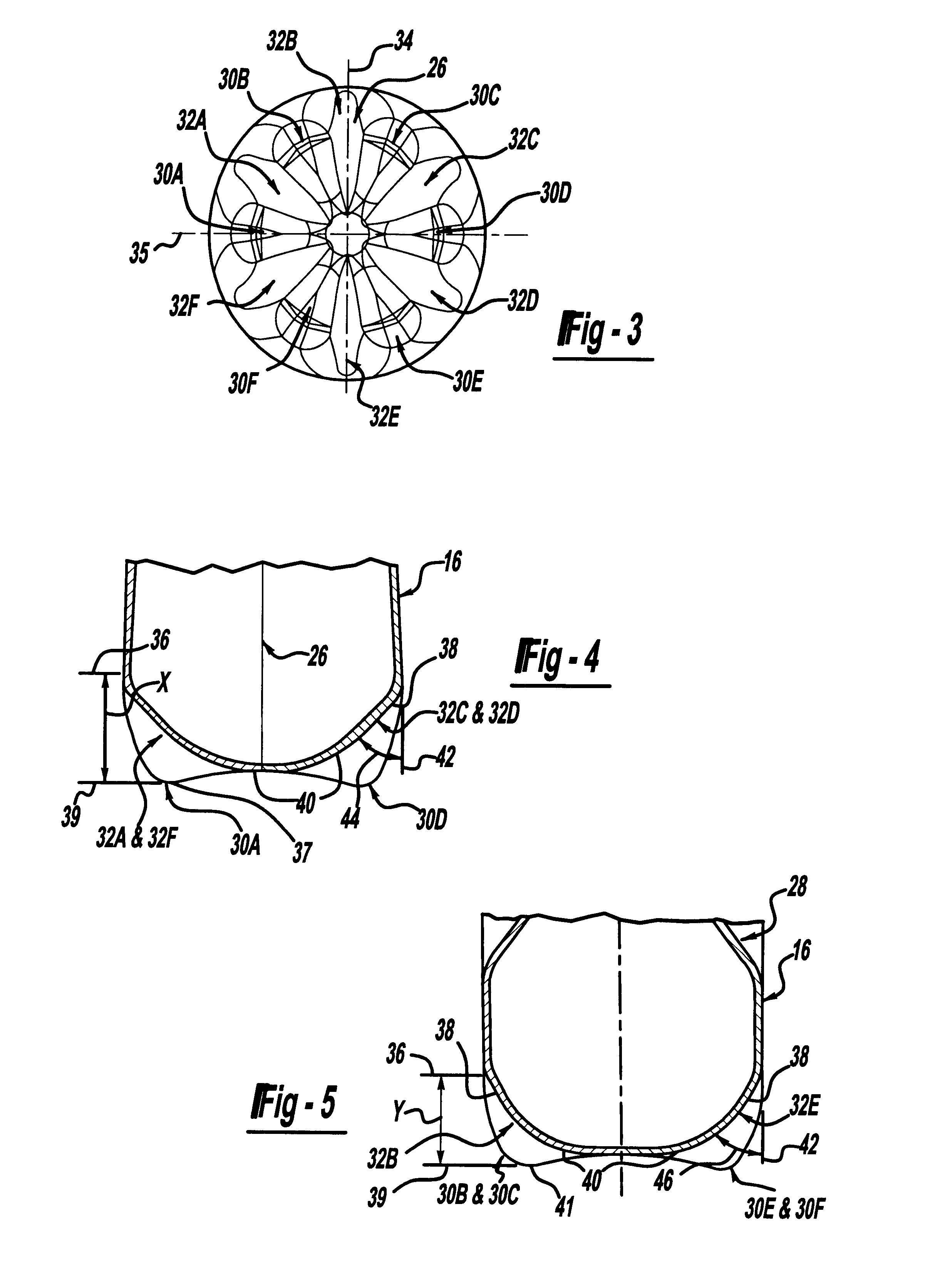

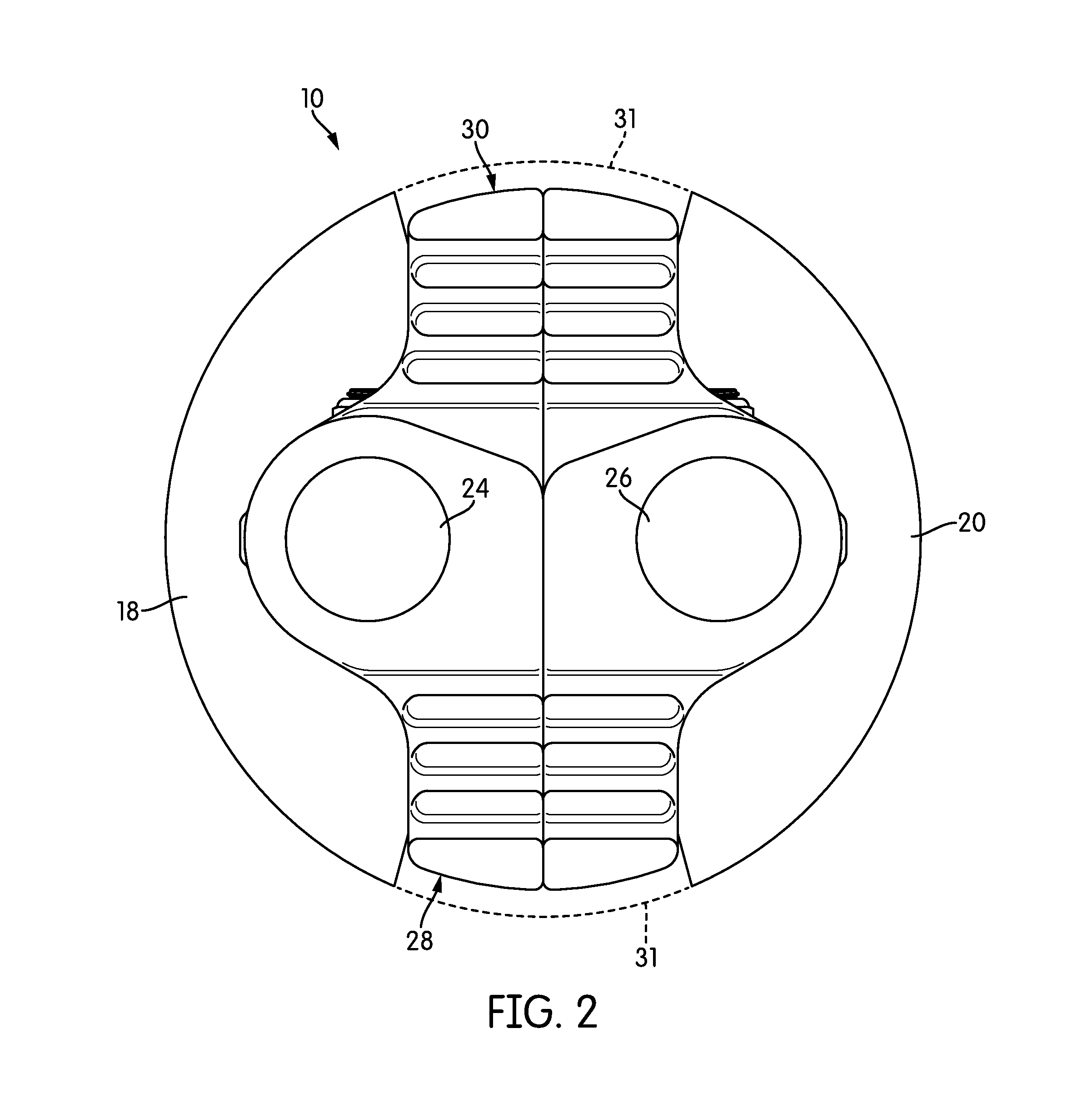

Non-rocking, webbed container for carbonated beverages

A blow molded plastic container including a neck finish, a shoulder portion, a sidewall, and a base integrally formed with one another. Two indentations in the sidewall create a handgrip and a web extends generally across the interior of the container between the two indentations. A plurality of generally downwardly extending support feet include short feet and long feet. Separating the support feet are a plurality of first and second strap formations. Support surface contact points of the long feet are in a planar relationship with respect to one another, thereby providing the container with stability when empty. After filling, capping and pressurizing, the support surface contact points of the short feet and the support surface contact points of the long feet are all in a planar relationship with respect to one another, thereby providing the container with stability when filled.

Owner:AMCOR RIGID PLASICS USA LLC

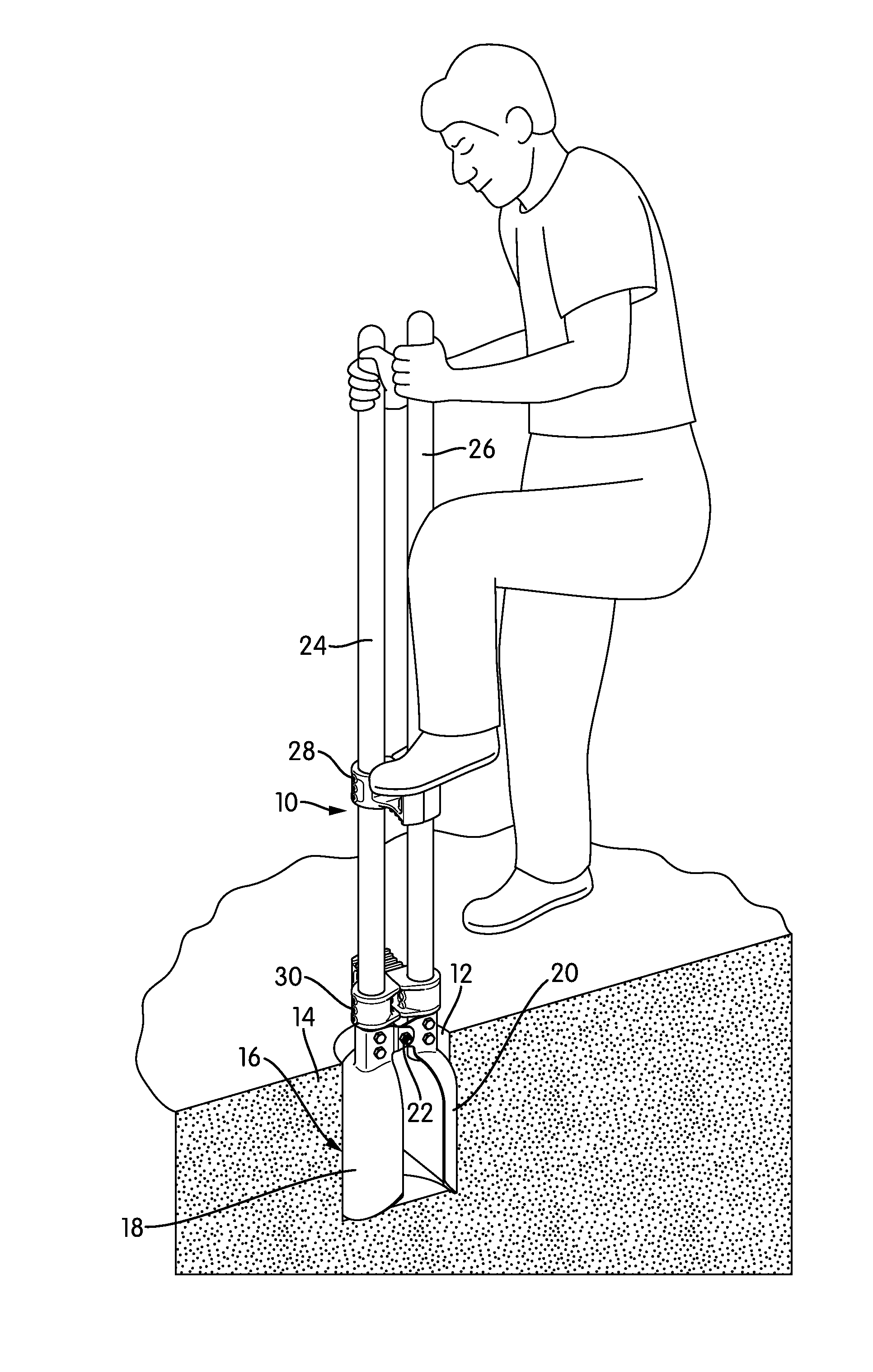

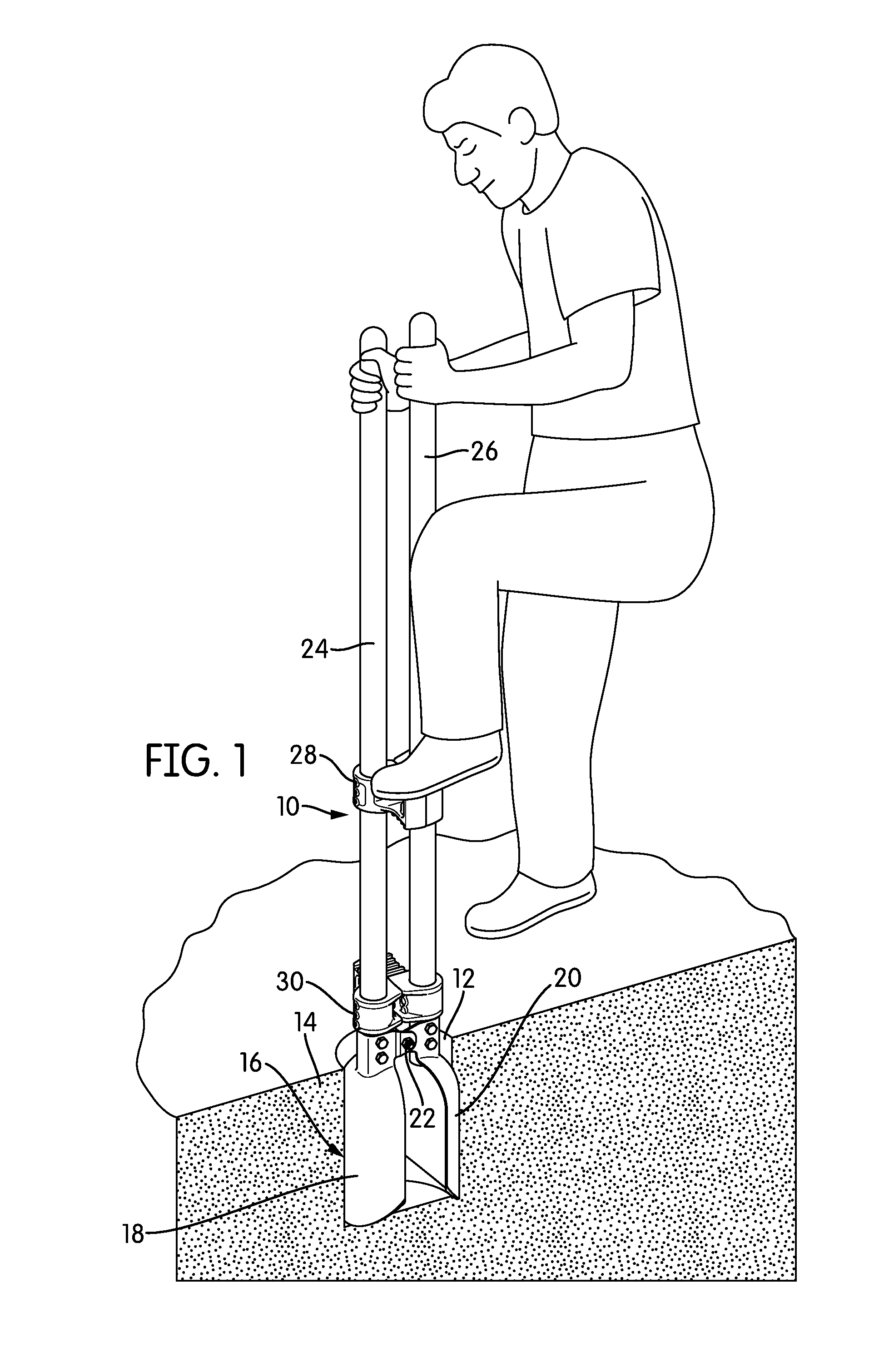

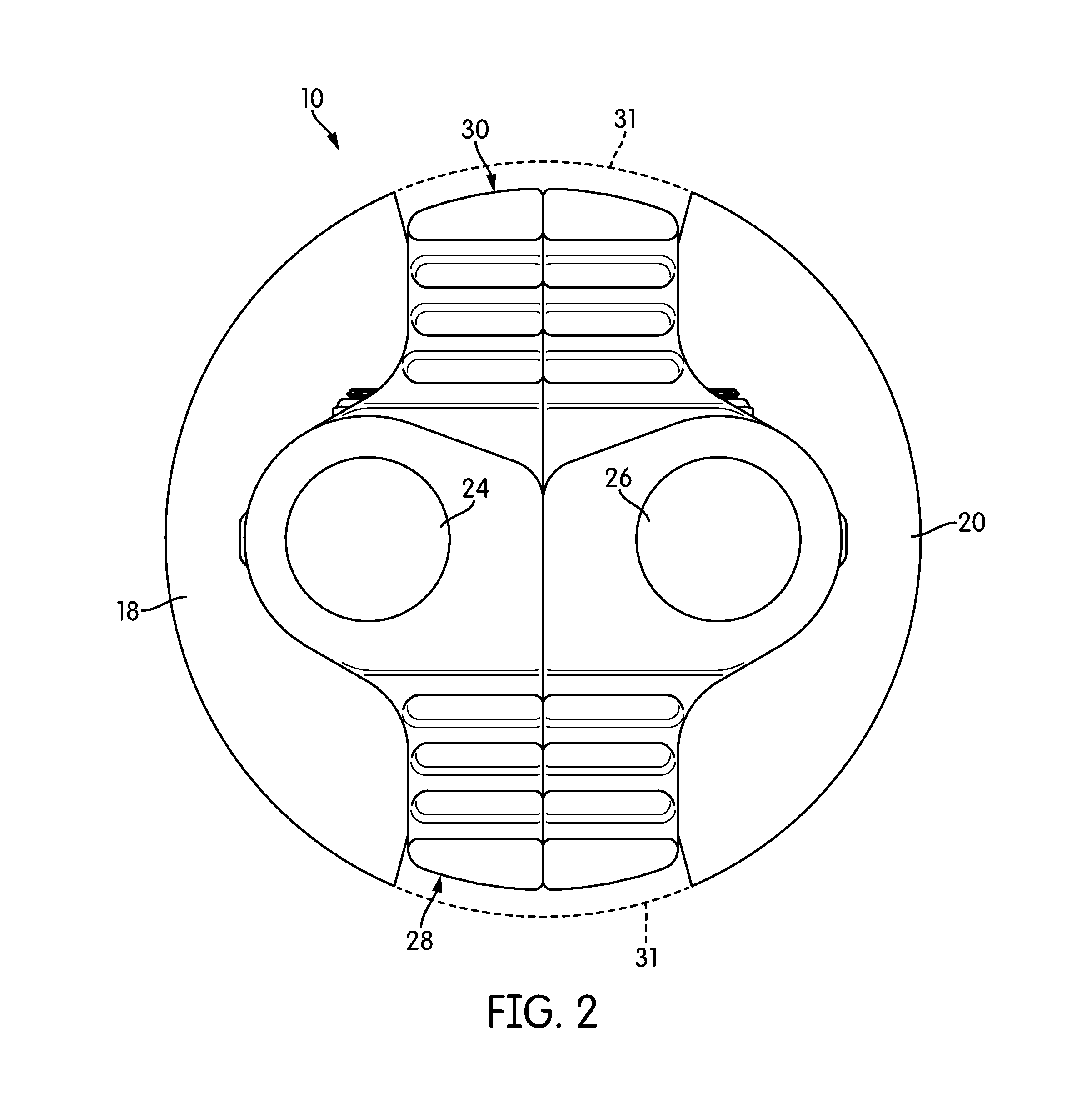

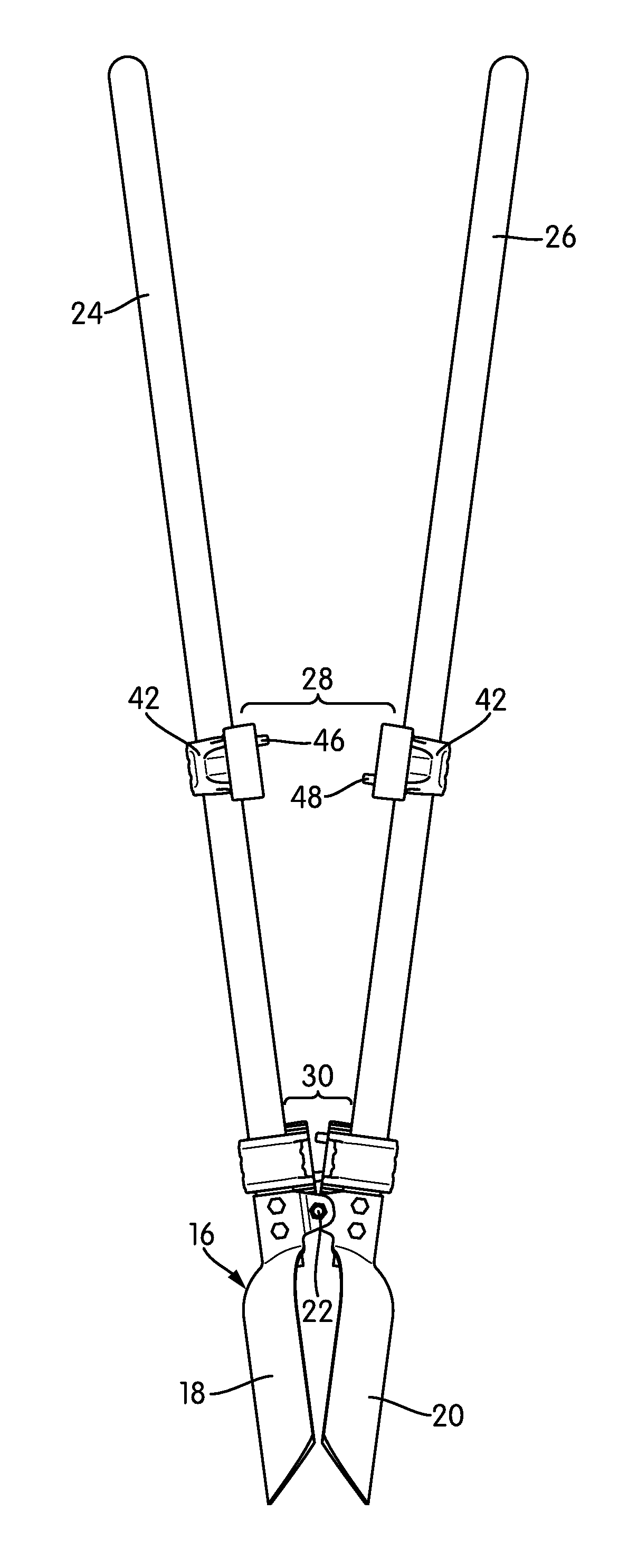

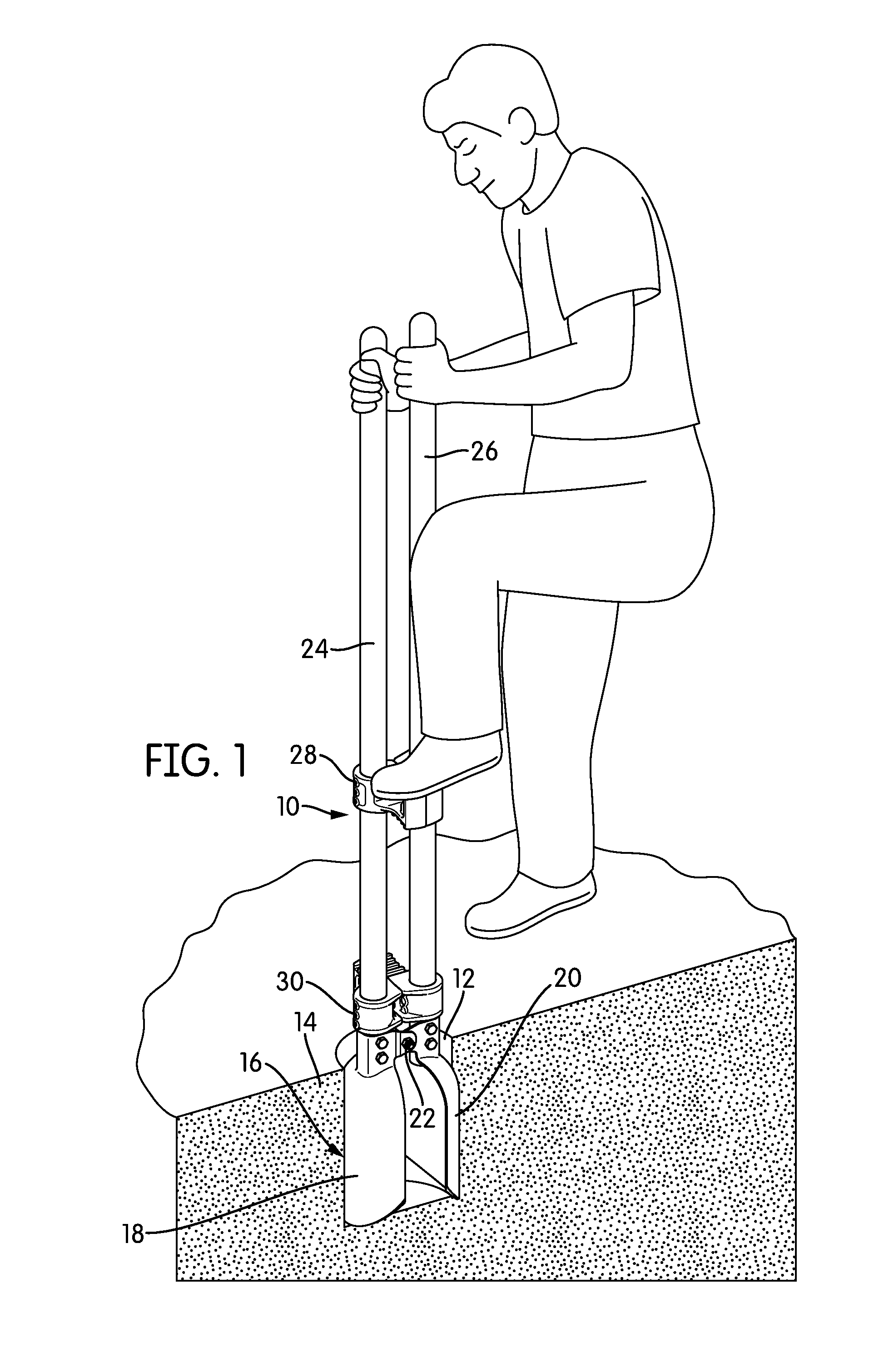

Post-Hole Digger with Foot Rests

Owner:HUDSON ANDREW JOHN +1

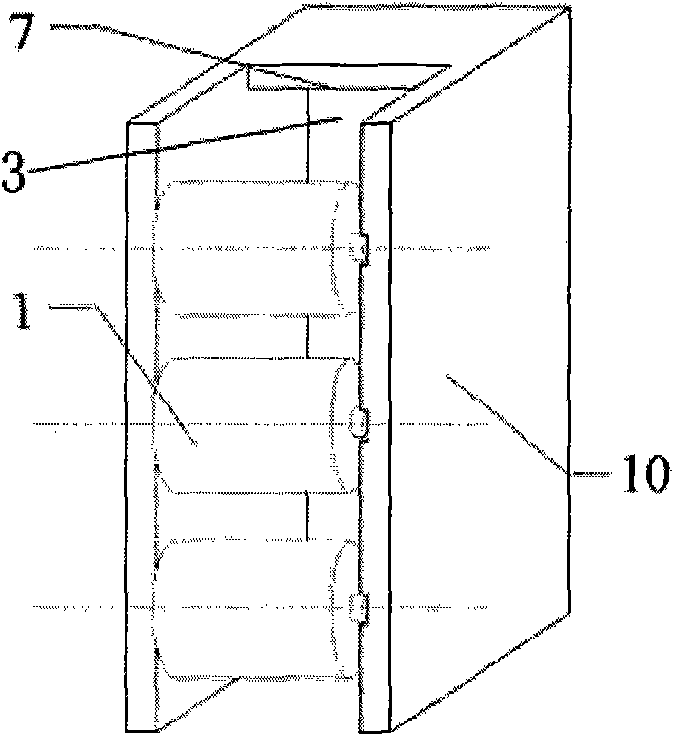

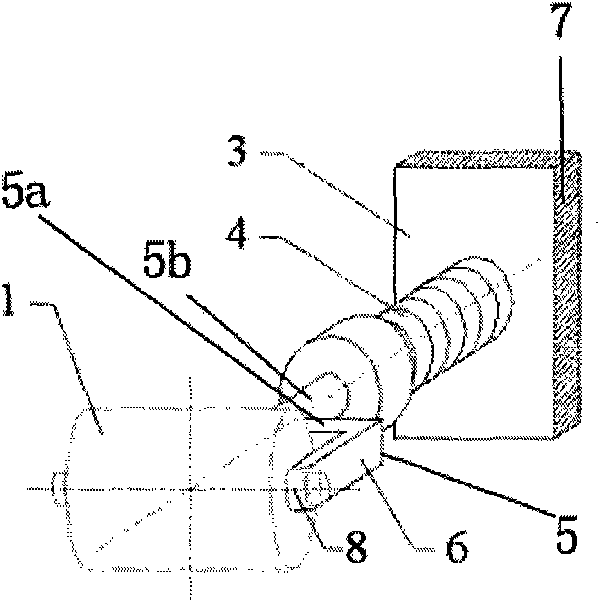

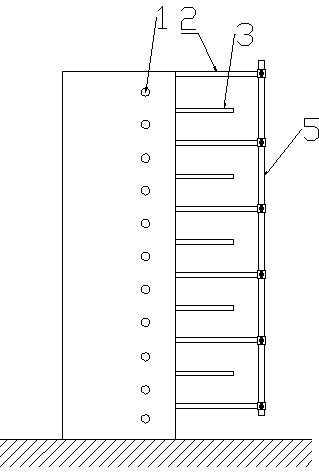

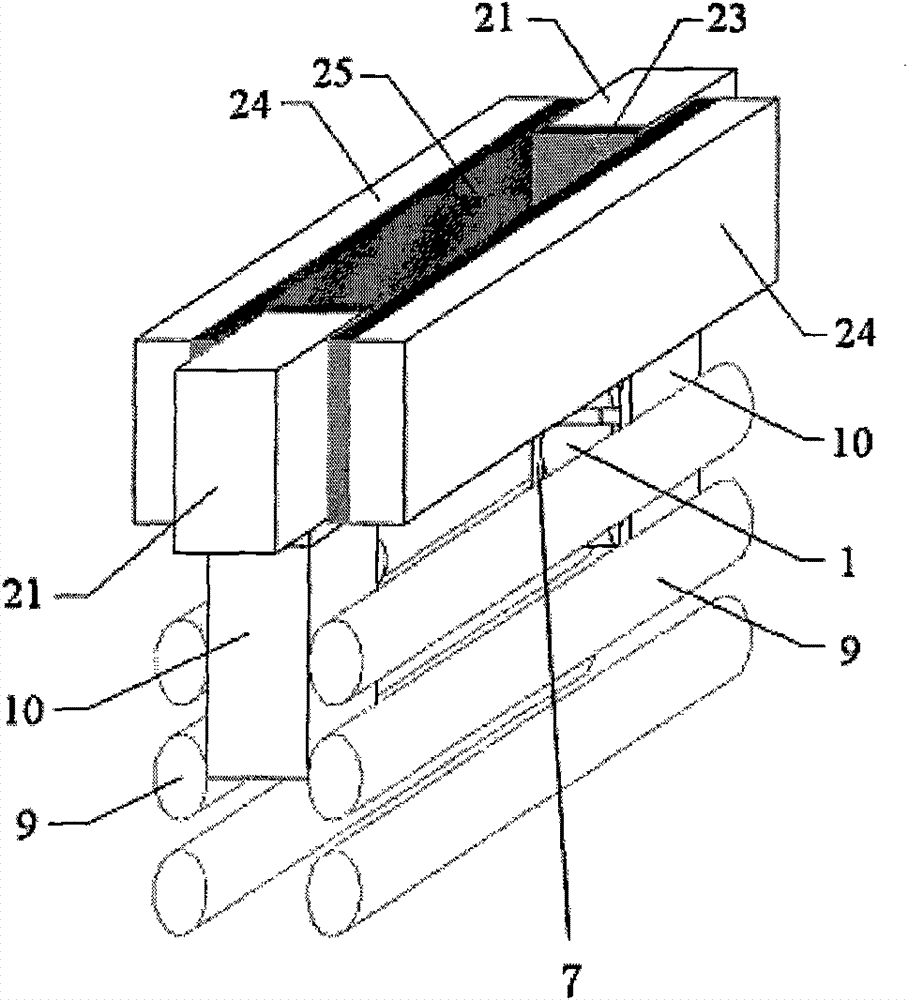

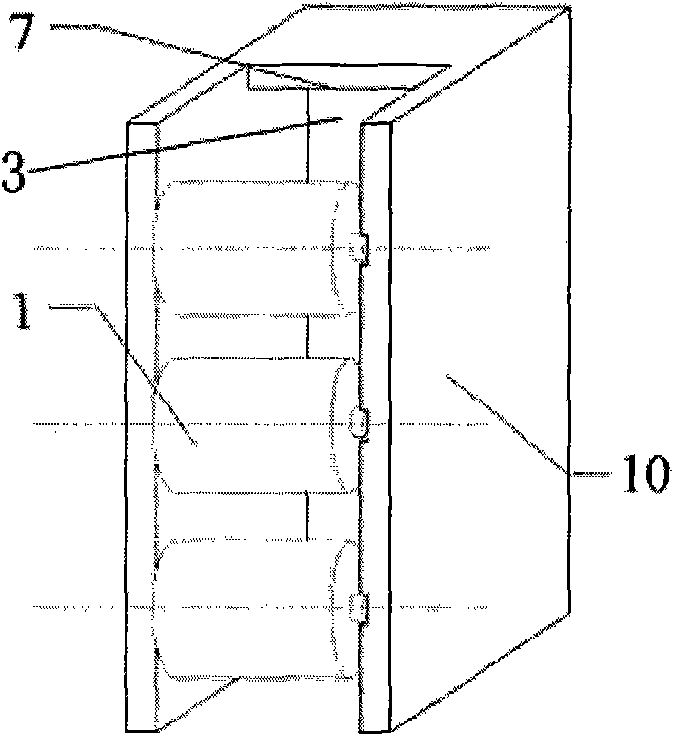

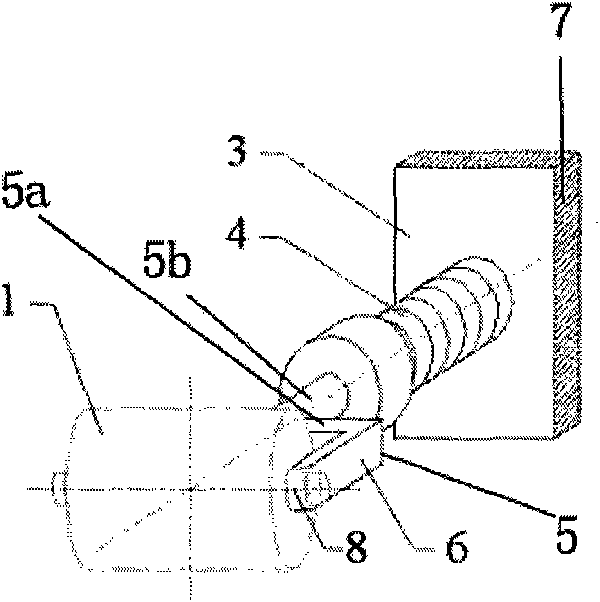

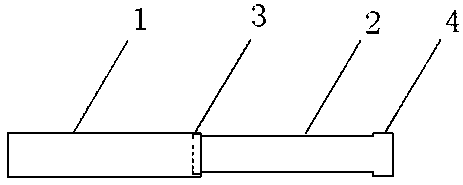

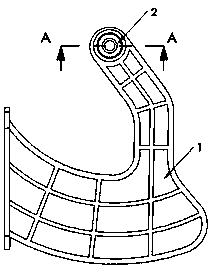

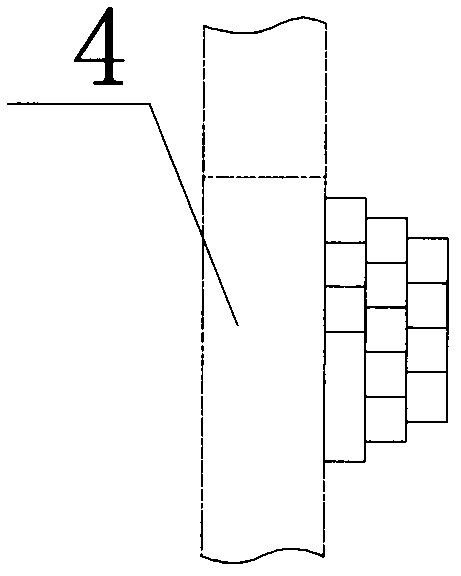

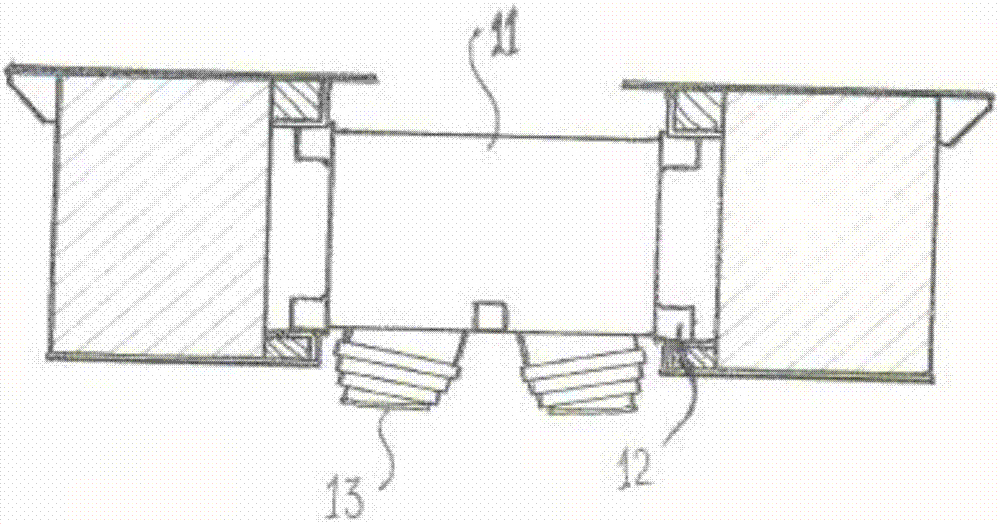

Foot roll support frame with multi-section short-side foot rolls

ActiveCN102151809AGood and effective supportThe phenomenon of not exceeding the angleWhole bodyEngineering

The invention discloses a foot roll support frame with multi-section short-side foot rolls. The inner wall surface (3) of a bracket side wall (11) is provided with more than three foot roll components (g) in sequence from up to down; each foot roll component comprises a short side foot roll (1), a foot roll bracket part (5) and a buffer spring (4); the foot roll bracket part (5) consists of two oppositely parallel root roll support arms (6), a cross frame (5a) and a strut (5b); one end of the buffer spring is fixed on the inner wall surface; the other end of the buffer spring is connected with the strut; the strut deviates from the center of the cross frame and is formed on one end of the cross frame; the short side foot roll comprises a short foot roll (1a), a medium foot roll (1b) and along foot roll (1c) which are respectively connected into a whole body by two shaft necks; the shaft necks are respectively, rotatably and freely arranged on the other ends of the two foot roll support arms, and are mounted as follows: the shaft necks in each pair of foot roll components are staggered with the shaft necks of the neighboring foot roll component. The foot roll support frame with the multi-section short-side foot rolls can inhibit the exceeding corners at the side surface of a casting blank shell, improve the angle quality of the casting blank, avoid bleed-out accident, and improve the production safety.

Owner:BAOSHAN IRON & STEEL CO LTD

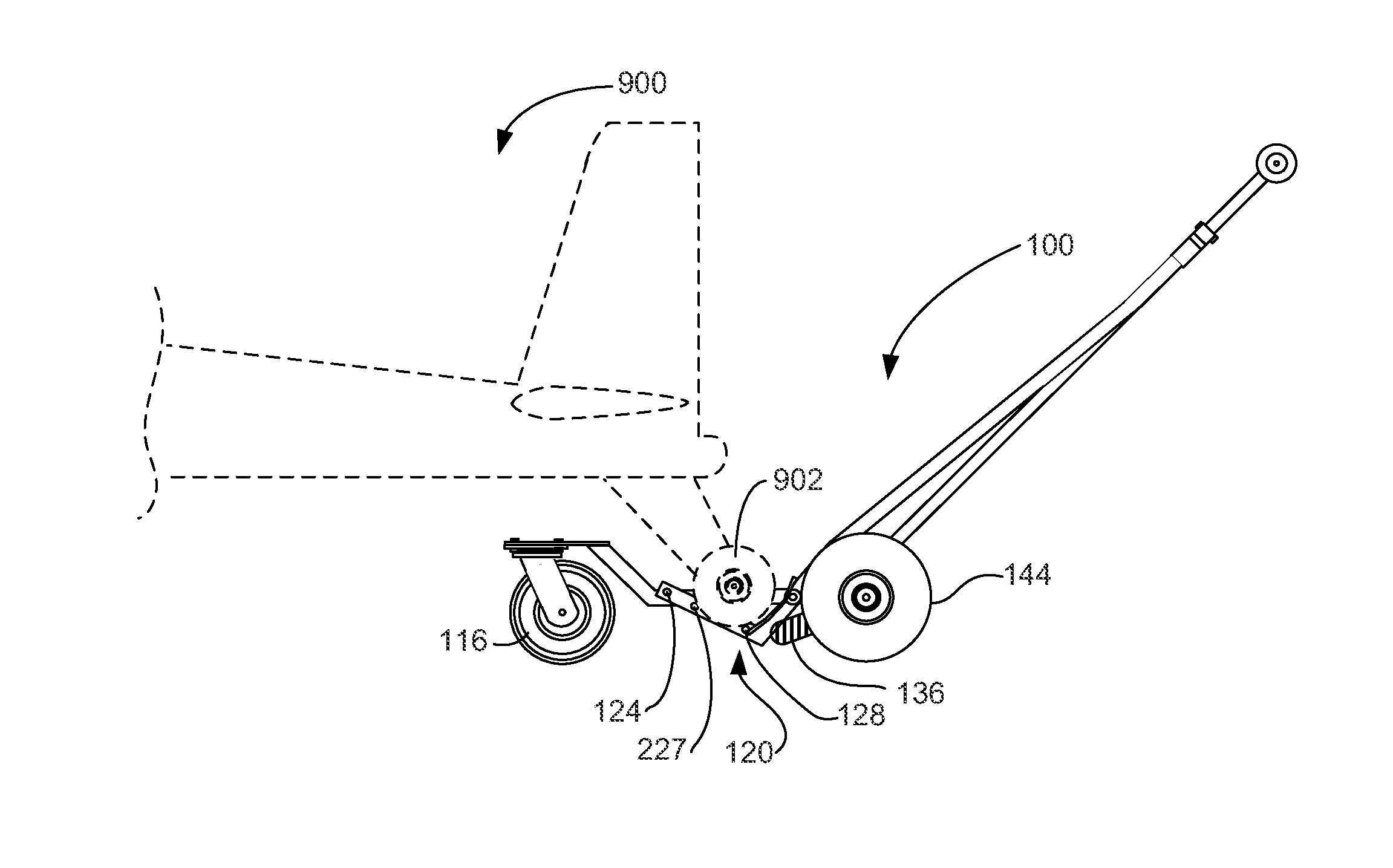

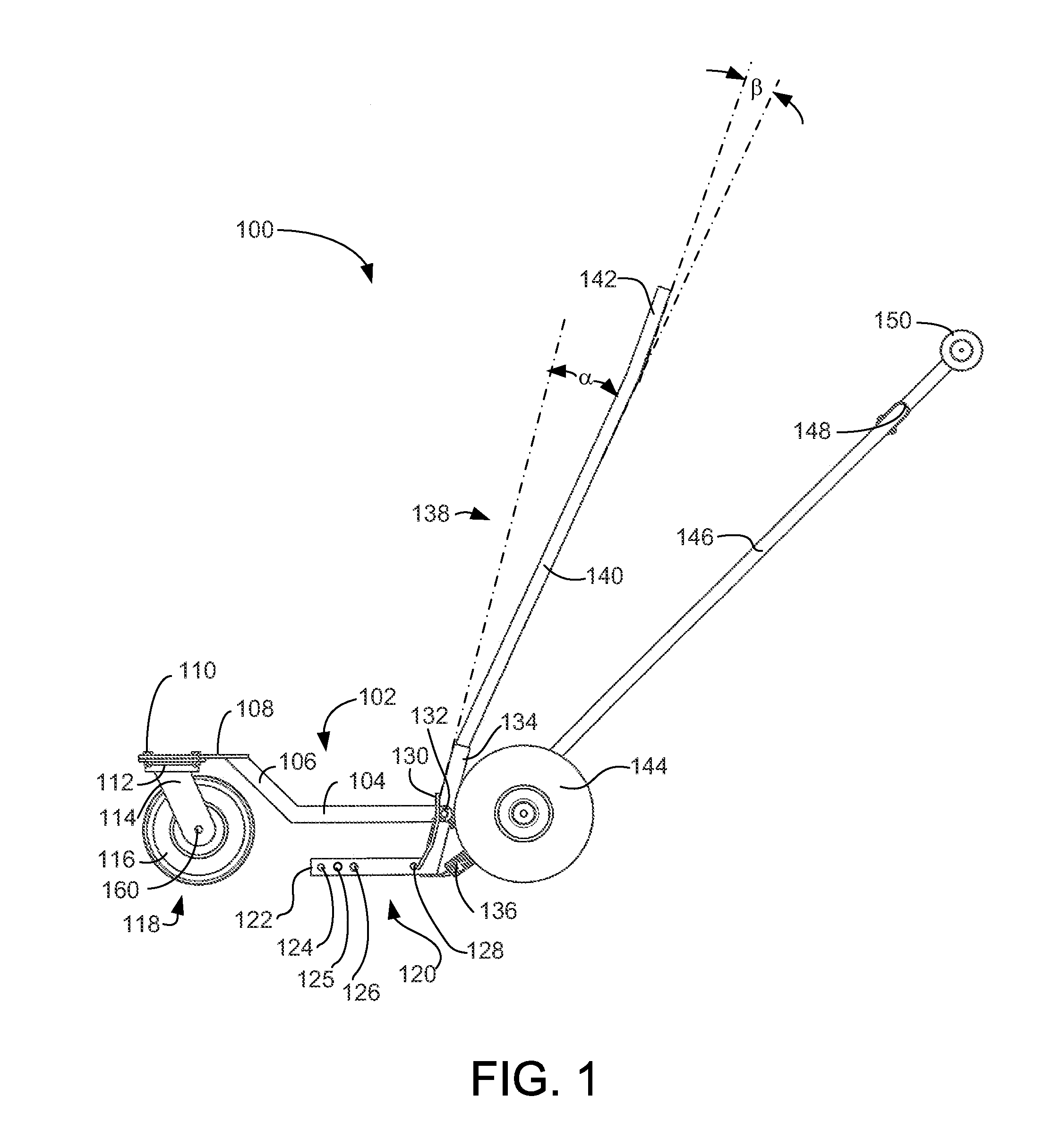

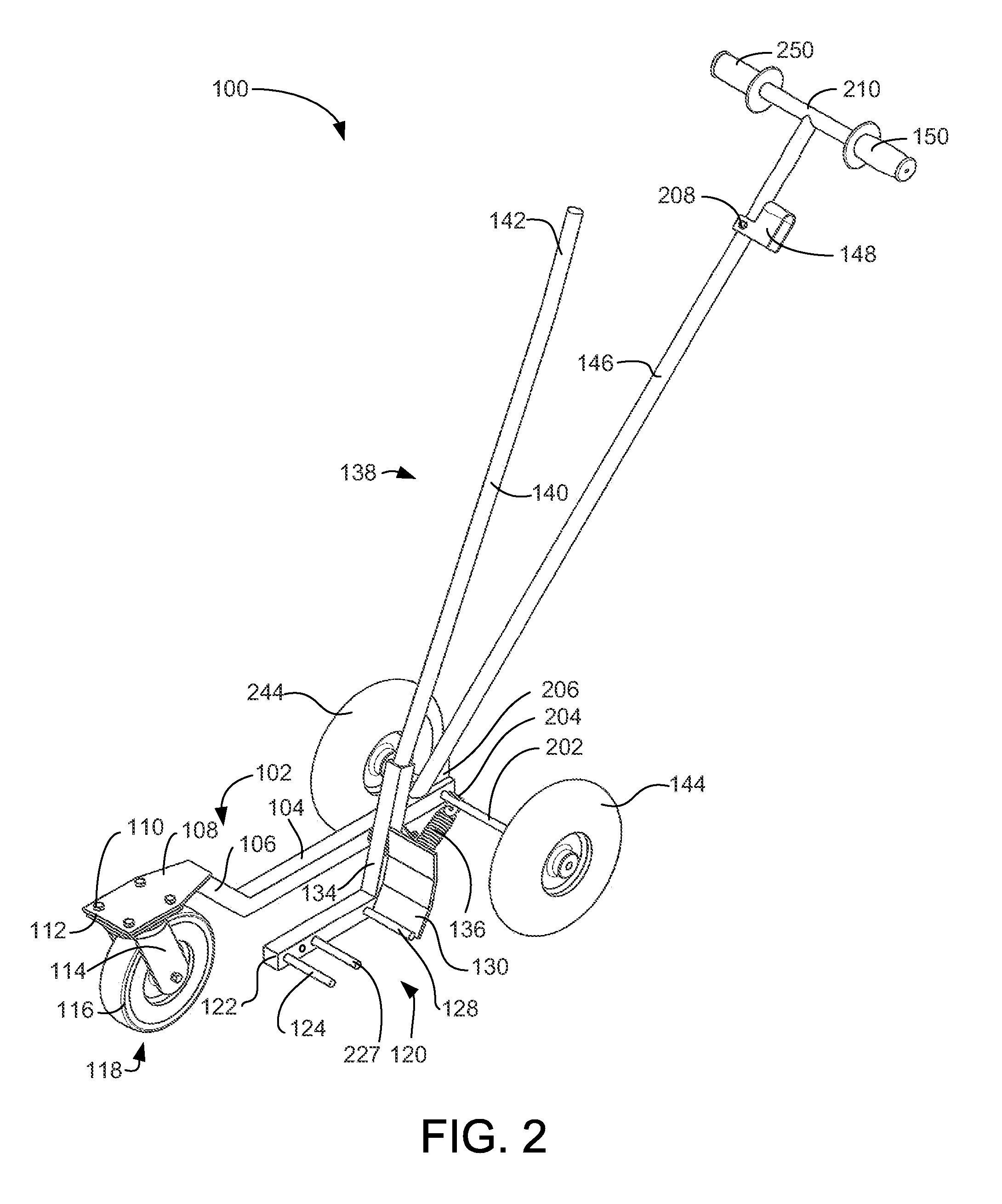

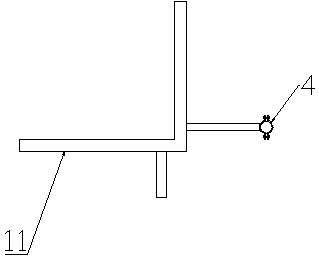

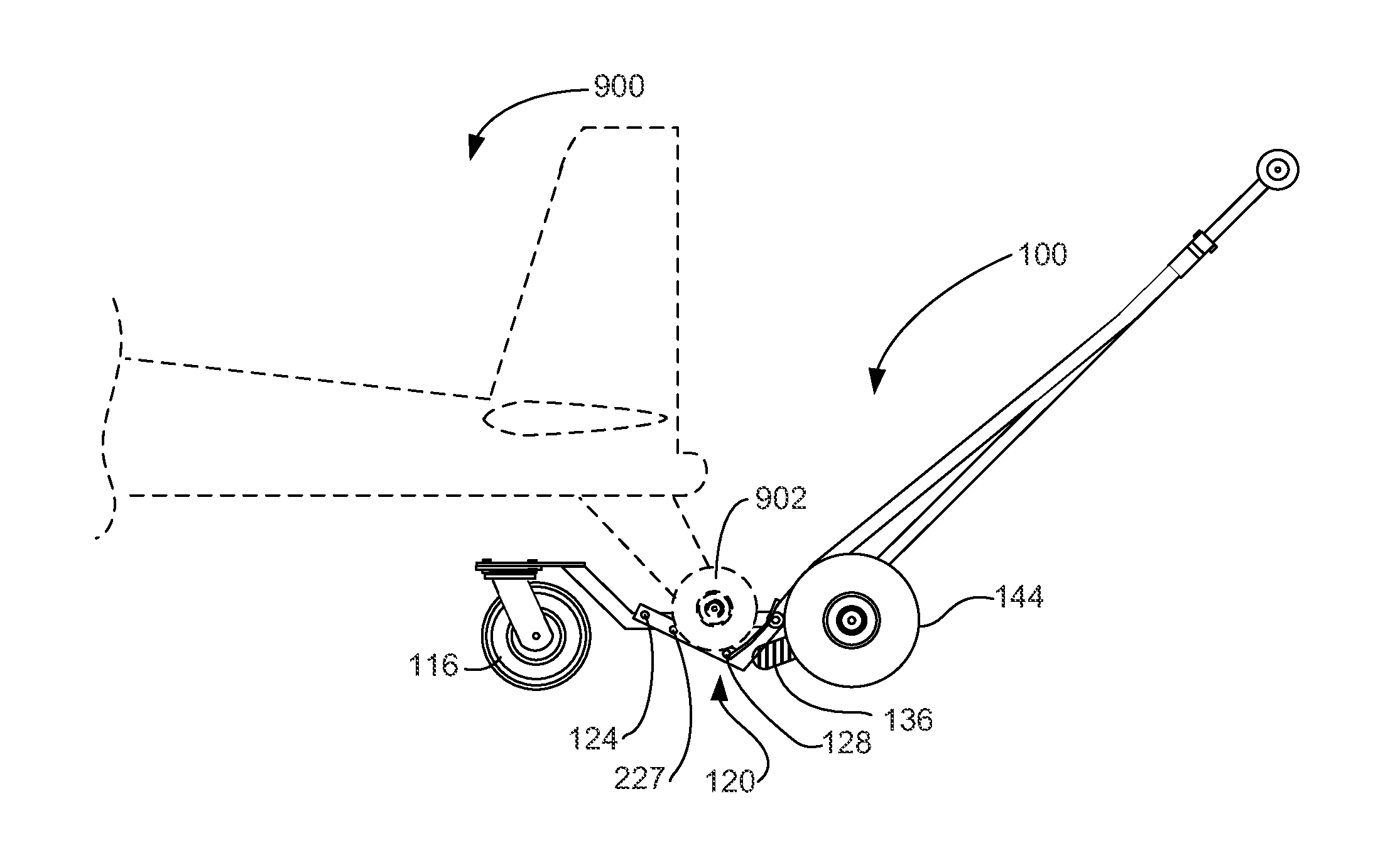

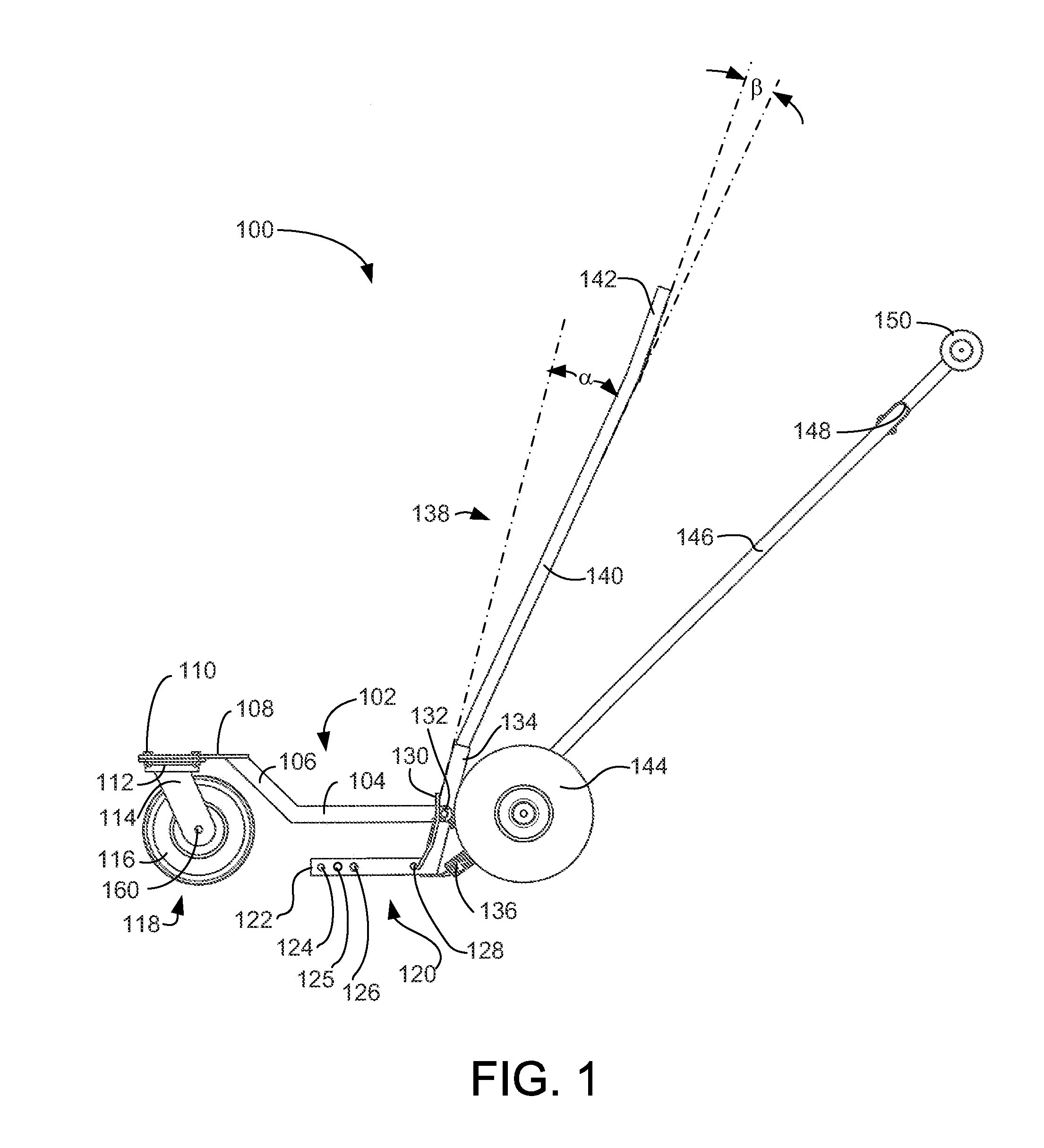

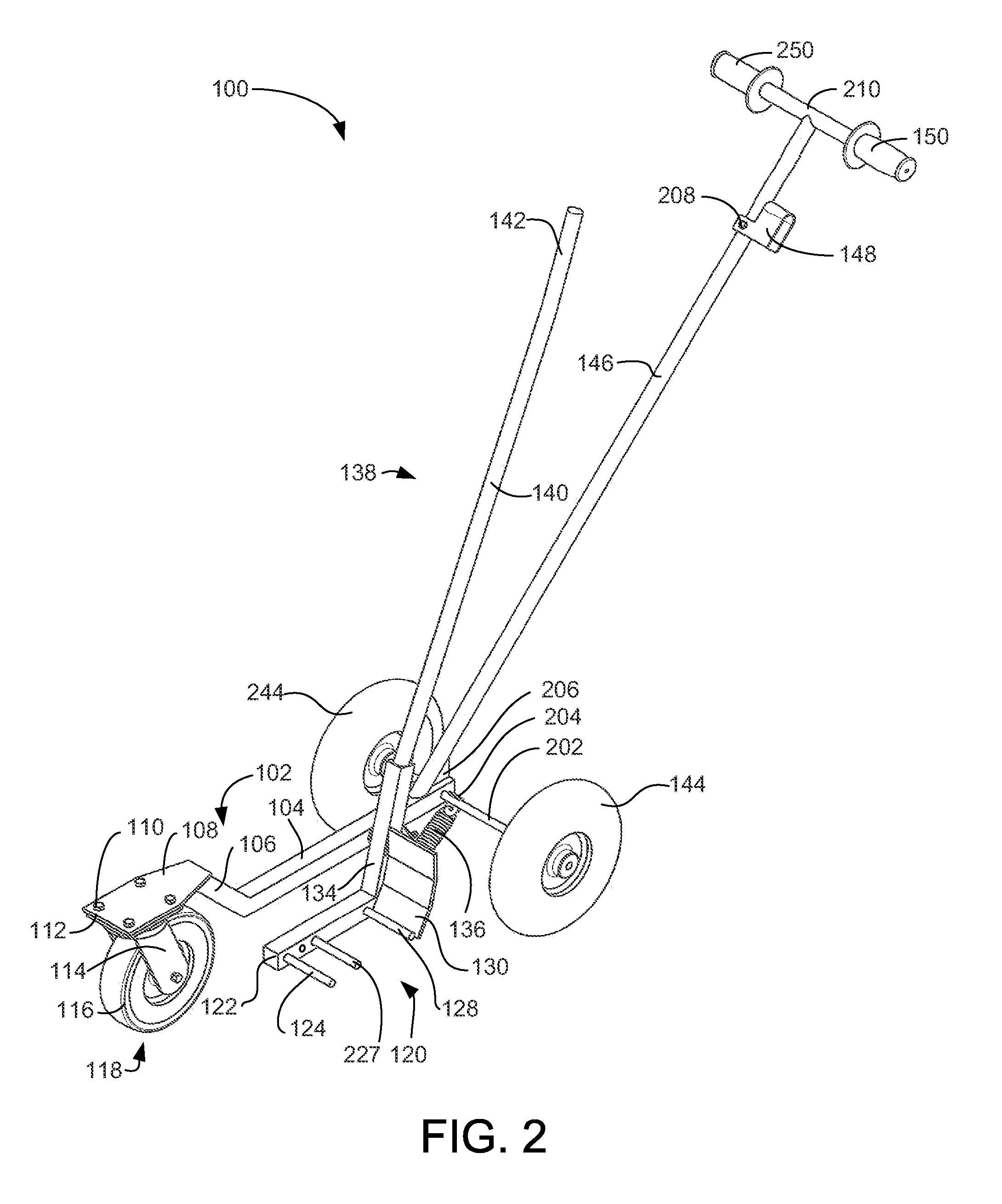

Tail Wheel Transporter

ActiveUS20120007335A1Easy steeringCheap manufacturingSupporting partsLifting devicesSingle beamRolling chassis

A tail wheel transporter with a single-beam chassis in a tricycle carriage and a towing arm extending from the single beam for towing and steering. The single beam is offset on the rear two-wheel axle to pivotably support a lifting arm, or lever, that is side mounted on the chassis. The short foot of the “L” supports one or more adjustable studs for initially engaging the underside of a tail wheel from the side. The lifting arm is manually operated to lift the tail wheel off the ground. In the lifted position, the lifting arm is latched to the towing arm so that constant manual force to maintain lift is not required. The tail wheel is received between the front and rear axles and exerts force below the height of at least some of the axles, so no manual force is required to maintain balance during operation.

Owner:PERRY DANIEL S

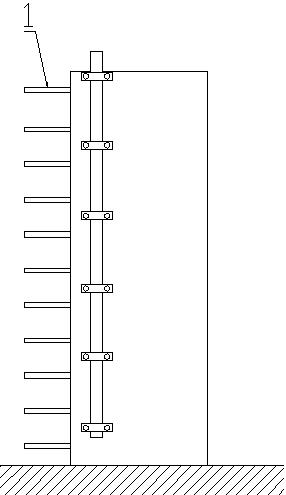

Method for preventing climber from falling in process of climbing tower

The invention provides a method for preventing a climber from falling in the process of climbing a tower. The method has the advantages that the structure is simple, operation is convenient, and safety precautions are taken. The method comprises the steps that a row of short foot nails which are evenly arranged in an up-down mode are fixedly welded to the surface of one side of angle steel of the iron tower to be climbed, and a row of long foot nails and short foot nails are fixedly welded to the surface of the other side of the angle steel, wherein the row of long foot nails and short foot nails are evenly and alternately arranged in an up-down mode; the foot nails on the two side faces of the angle steel are arranged alternately; a safety rod is mounted at the top ends of the long foot nails through fixtures; a protection rope is fixedly arranged at the back side of a climbing protection safety belt and provided with two lead-out ends which are respectively provided with a snap ring; a worker ties the safety belt well, buckles the first snap ring to the first section of the safety rod and then starts to step on the foot nails to climb the tower upwards; the worker buckles the second snap ring to the second section of the safety rod when arriving at the second long foot nail, and simultaneously picks off the first snap ring; the worker repeats the steps again and again until the worker arrives at a designated position; the worker can conduct reverse operation to get to the ground after maintenance; the worker unties the safety belt after going back to the ground.

Owner:STATE GRID CORP OF CHINA +1

Tail wheel transporter

ActiveUS8336900B2Easy steeringCheap manufacturingSupporting partsVehicle manoeuvring devicesSingle beamRolling chassis

A tail wheel transporter with a single-beam chassis in a tricycle carriage and a towing arm extending from the single beam for towing and steering. The single beam is offset on the rear two-wheel axle to pivotably support a lifting arm, or lever, that is side mounted on the chassis. The short foot of the “L” supports one or more adjustable studs for initially engaging the underside of a tail wheel from the side. The lifting arm is manually operated to lift the tail wheel off the ground. In the lifted position, the lifting arm is latched to the towing arm so that constant manual force to maintain lift is not required. The tail wheel is received between the front and rear axles and exerts force below the height of at least some of the axles, so no manual force is required to maintain balance during operation.

Owner:PERRY DANIEL S

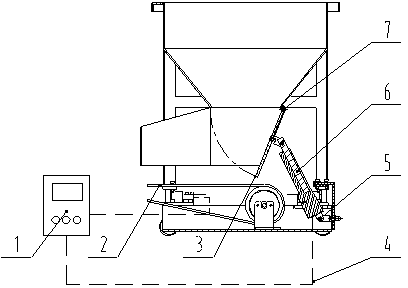

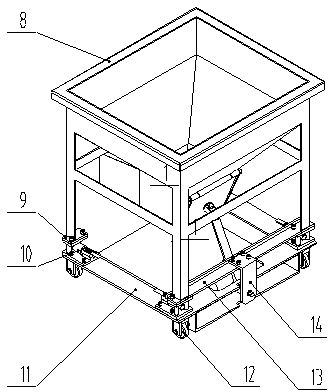

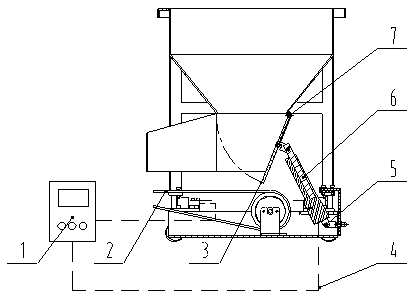

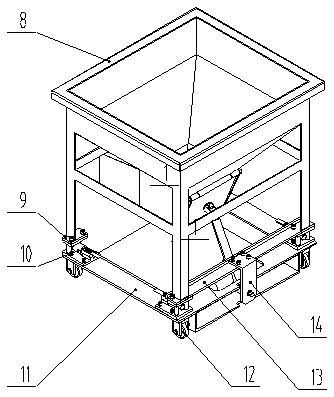

Device with weighing and automatic blanking functions

ActiveCN103407798AAvoid lostReduce labor intensityLarge containersLoading/unloadingEngineeringLoad cell

A device with weighing and automatic blanking functions comprises a control device, a conveying device, a blanking door, communication lines, push rod hinge parts, an electric push rod, a door hinge, a hopper, a short foot plate, a weighing sensor, a hopper seat, foot wheels, a long foot plate and a connection plate. The device with the weighing and automatic blanking functions is characterized in that the short foot plate and the long foot plate are arranged at the bottom of the hopper, the weighing sensor is connected to the lower portions of the short foot plate and the long foot plate and connected with the hopper seat, the connection plate is arranged on the long foot plate, the foot wheels are arranged on the hopper seat, the conveying device is arranged below the hopper and positioned on the hopper seat, the hopper is connected with the blanking door through the door hinge, the blanking door is connected with the electric push rod through the push rod hinge part, the electric push rod is connected with the connection plate through the push rod hinge part, and the control device is connected with the weighing sensor and the electric push rod through the communication lines. The device has the weighing and automatic blanking functions, no material is lost in use, and labor intensity of operators is reduced.

Owner:JIANGXI GUANGMING INTELLIGENT TECH CO LTD

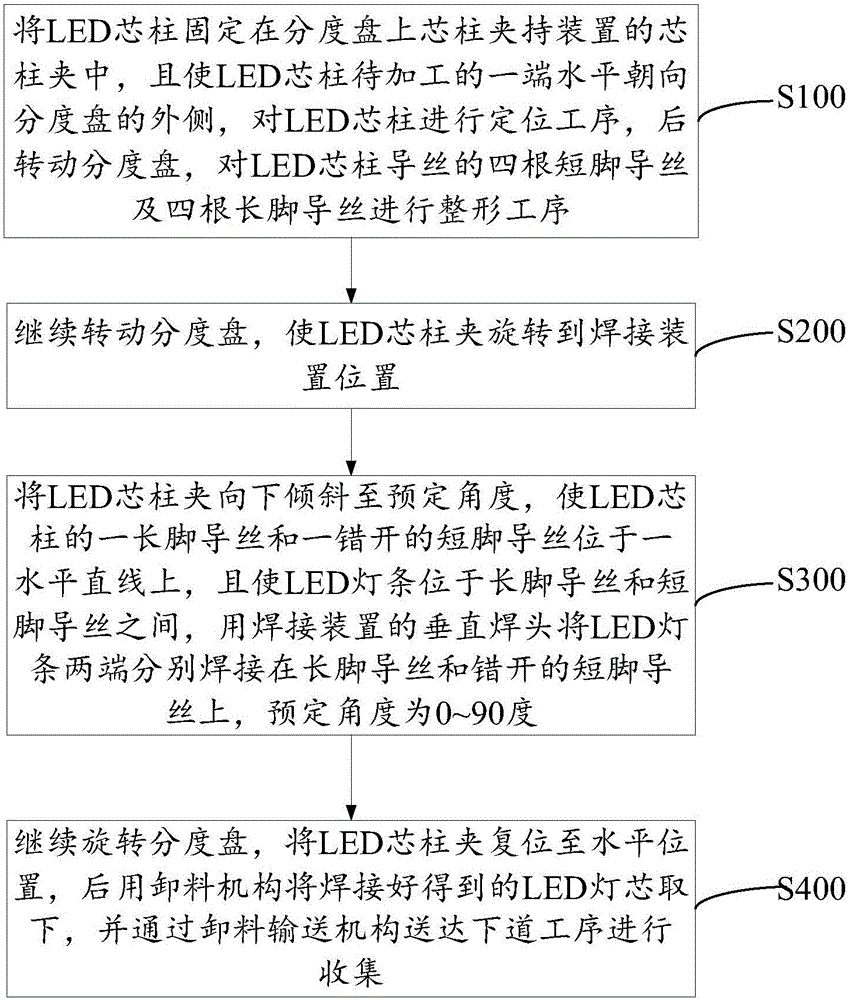

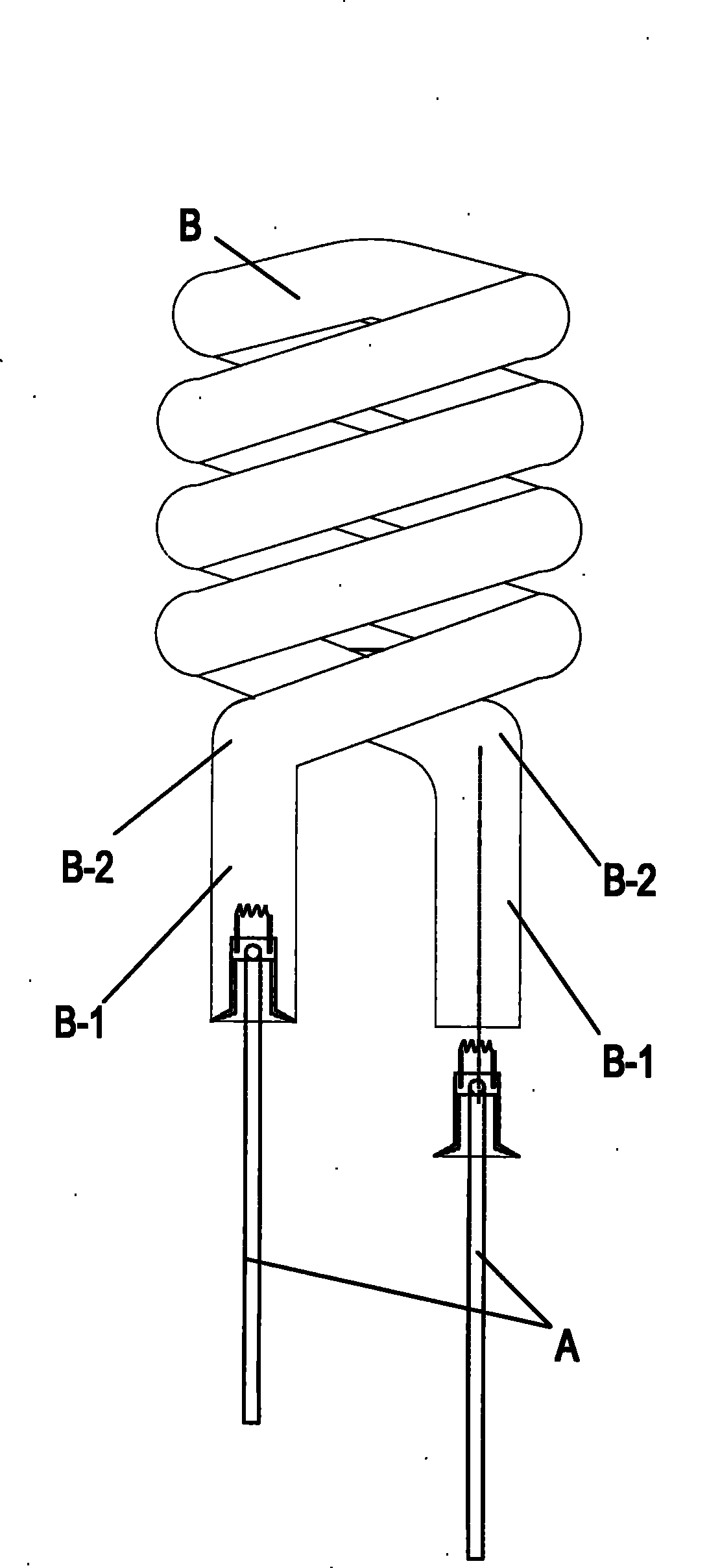

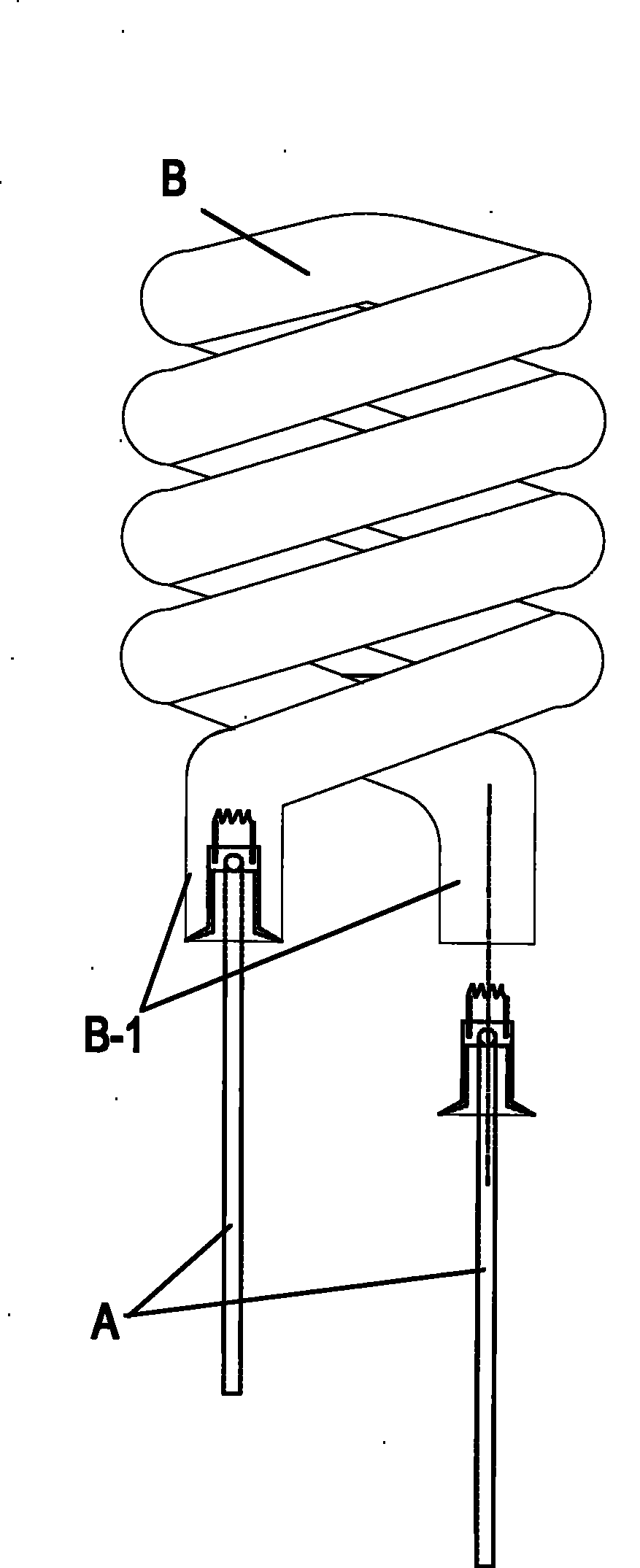

Welding method of LED wick

InactiveCN106001830AReduce manufacturing costLow costWelding/soldering/cutting articlesMetal working apparatusEngineeringLED lamp

The invention provides an LED wick welding method. The LED wick welding method includes the following steps: fixing the LED stem in the stem clip of the stem clamping device, performing a shaping process on the four short-leg guide wires and the four long-leg guide wires of the LED stem; The LED stem clip is inclined downward to a predetermined angle, so that a long-leg guide wire and a staggered short-leg guide wire of the LED stem are located on a horizontal straight line, and the LED light bar is positioned between the long-leg guide wire and the short-leg guide wire. Between; reset the LED stem clamp to the horizontal position, and then use the unloading mechanism to remove the welded LED wick. In the above-mentioned LED wick welding method, since the stem clamping device is tilted during the welding process so that the long-leg guide wire and the staggered short-leg guide wire are located on the same horizontal plane, the welding process for the spiral LED wick is realized, and the automatic welding operation is realized. The working efficiency is greatly improved, and the production cost of the whole LED wick is reduced.

Owner:镇江晨光焊接设备制造有限公司

Post-hole digger with foot rests

A foot rest for a post-hole digger and post-hole diggers using the foot rest are disclosed. The foot rest includes two portions, one attached to each shaft of the post-hole digger. The two portions have structure that allows them to engage one another when the two shafts of the post-hole digger are vertical. The foot rest does not extend beyond the bore diameter of the post-hole digger. Thus, in order to keep the user's feet on the relatively short foot rest, the contact surface of the foot rest may be angled. In some embodiments, the foot rest may be symmetrical, so that either side may be used as the upper surface. A post-hole digger including the foot rests typically includes at least two foot rests, spaced from one another and facing different directions along the shafts of the tool.

Owner:HUDSON ANDREW JOHN +1

Foot roll support frame with multi-section short-side foot rolls

ActiveCN102151809BGood and effective supportThe phenomenon of not exceeding the angleWhole bodyEngineering

The invention discloses a foot roll support frame with multi-section short-side foot rolls. The inner wall surface (3) of a bracket side wall (11) is provided with more than three foot roll components (g) in sequence from up to down; each foot roll component comprises a short side foot roll (1), a foot roll bracket part (5) and a buffer spring (4); the foot roll bracket part (5) consists of two oppositely parallel root roll support arms (6), a cross frame (5a) and a strut (5b); one end of the buffer spring is fixed on the inner wall surface; the other end of the buffer spring is connected with the strut; the strut deviates from the center of the cross frame and is formed on one end of the cross frame; the short side foot roll comprises a short foot roll (1a), a medium foot roll (1b) and along foot roll (1c) which are respectively connected into a whole body by two shaft necks; the shaft necks are respectively, rotatably and freely arranged on the other ends of the two foot roll support arms, and are mounted as follows: the shaft necks in each pair of foot roll components are staggered with the shaft necks of the neighboring foot roll component. The foot roll support frame with the multi-section short-side foot rolls can inhibit the exceeding corners at the side surface of a casting blank shell, improve the angle quality of the casting blank, avoid bleed-out accident, and improve the production safety.

Owner:BAOSHAN IRON & STEEL CO LTD

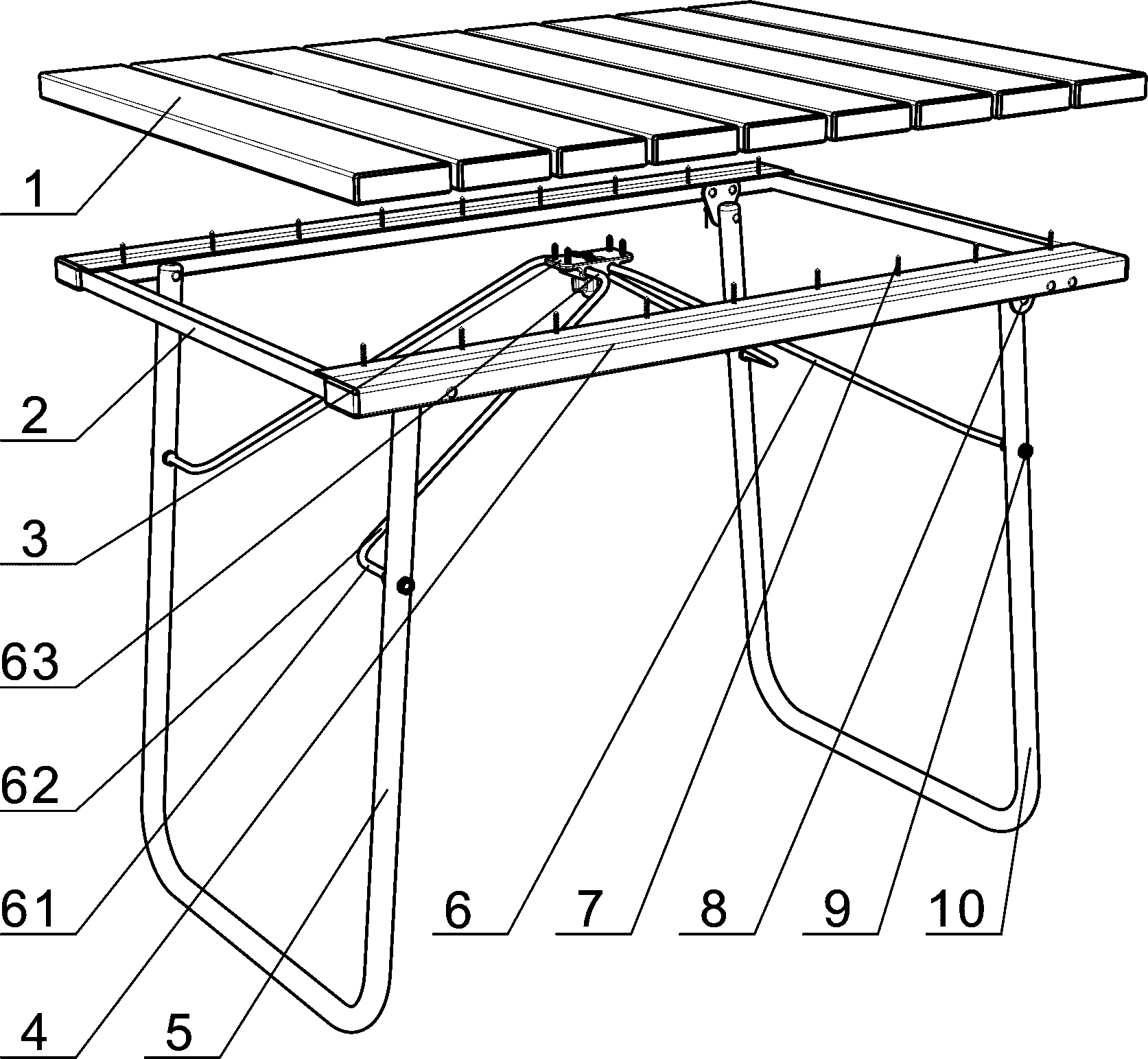

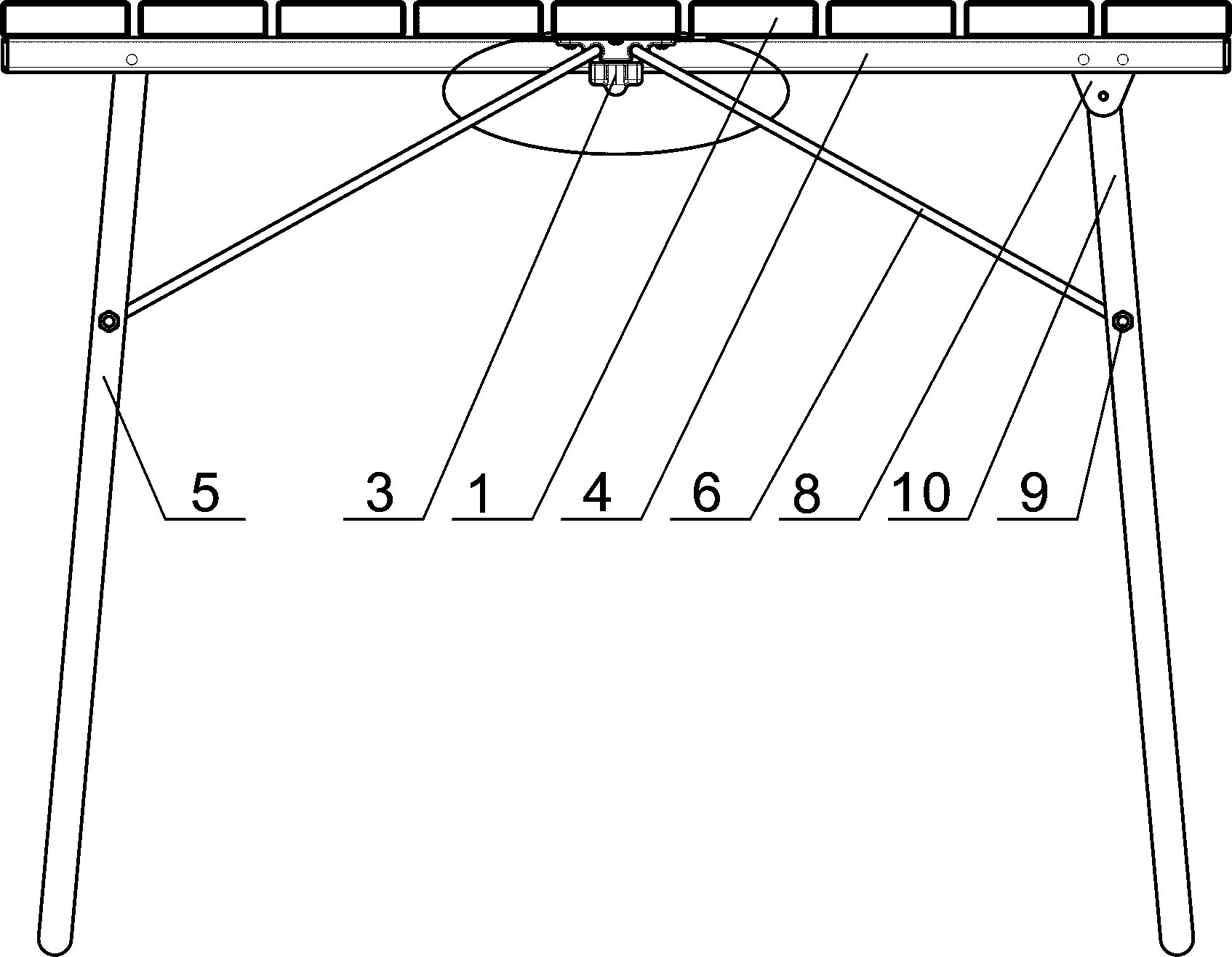

Folding picnic table

InactiveCN103783817ASimple structureEasy to operateFoldable tablesStowable tablesEngineeringShort foot

The invention discloses a folding picnic table. A table top plate is fixedly arranged on a framework which is formed by table frame pipes and cross beam pipes; a long foot pipe and the table frame pipes are hinged; positioning pieces are fixedly connected to the tale frame pipes; a short foot pipe and the positioning pieces are hinged; the table frame pipe, the long foot pipe and an obliquely supporting pipe and the table frame pipe, the short foot pipe and the obliquely supporting pipe are formed into two symmetrically arranged triangular mechanisms to support the table top plate to achieve unfolding and folding of the folding picnic table. The folding picnic table has the advantages of being simple in structure, convenient to operate and suitable for utilization in indoor, courtyard, camping and the like occasions.

Owner:郑雪峰

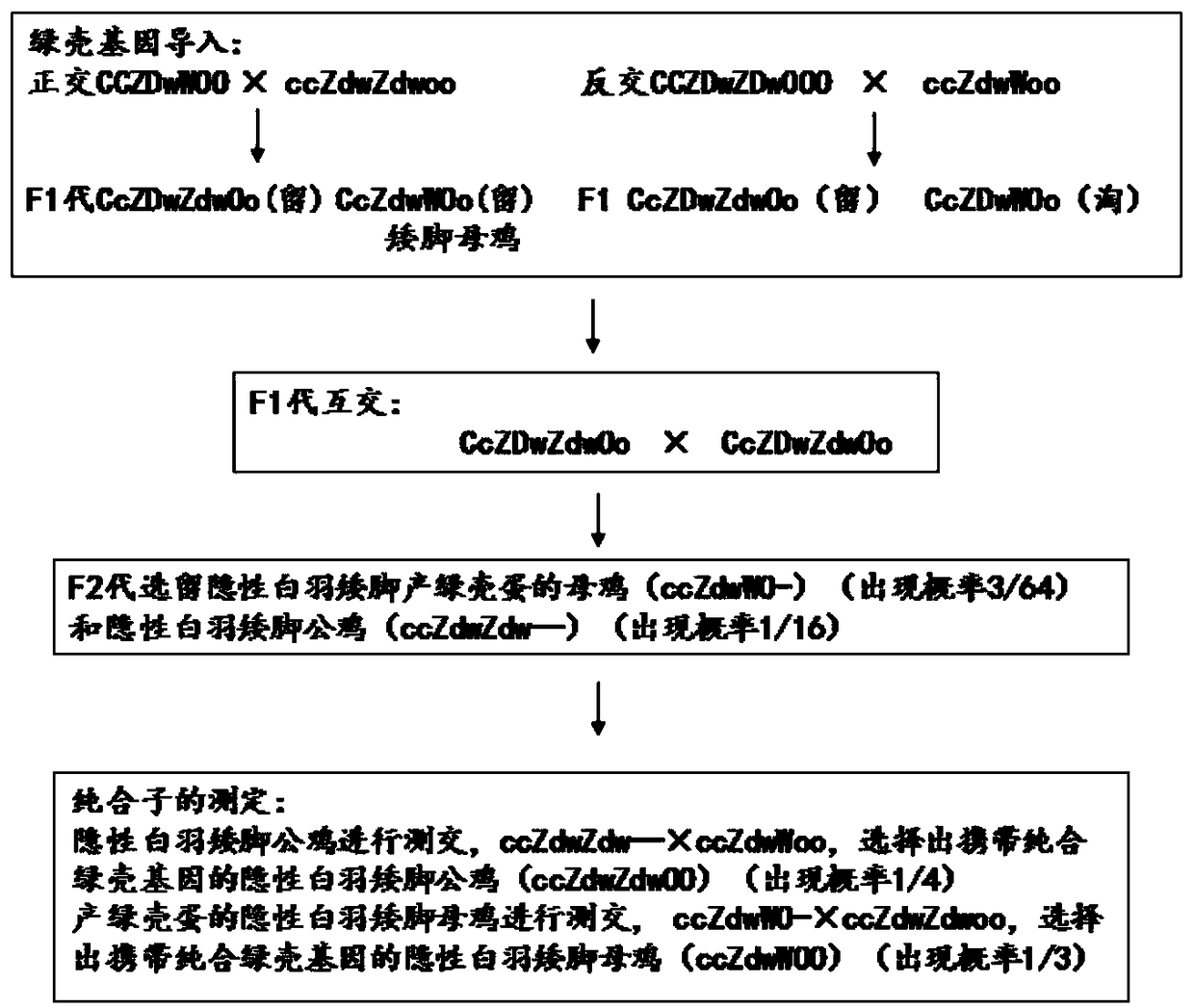

Method for breeding recessive white-feather short-foot green-shell high-yield laying hens

The invention relates to a method for breeding recessive white-feather short-foot green-shell high-yield laying hens. Green-shell genes of the green-shell laying hens are introduced into recessive white-feather short-foot chicken population, recessive white-feather short-foot cocks and hens with homozygous green-shell genes are obtained through hybridization and test mating, the obtained recessivewhite-feather short-foot cocks and hens with the homozygous green-shell genes are utilized for forming a family, breeding and population expanding are conducted through family selection and individual selection, and the recessive white-feather short-foot green-shell high-yield laying hens are bred. By means of the method, the recessive white-feather short-foot green-shell laying hens with high egg laying yield and genetic stability can be bred.

Owner:湖北欣华生态畜禽开发有限公司

Retractable ruler

The invention discloses a retractable straightedge, which comprises a ruler body with scales, and the ruler body is composed of at least two short rulers nested with each other, and the ruler body is coated with a fluorescent layer. The advantages of the present invention are: (1) The ruler of the present invention is composed of at least two short rulers that are nested with each other. The short rulers can be stretched and contracted, which is convenient for use and storage, and is convenient and practical. (2) The body of the ruler is coated with a fluorescent layer, so that when in use, even in a dark environment, people can still observe the scale on the ruler board through the light emitted by the fluorescent strip, so as to achieve the effect of accurate measurement. Convenient and practical.

Owner:南通豪鼎光伏科技有限公司

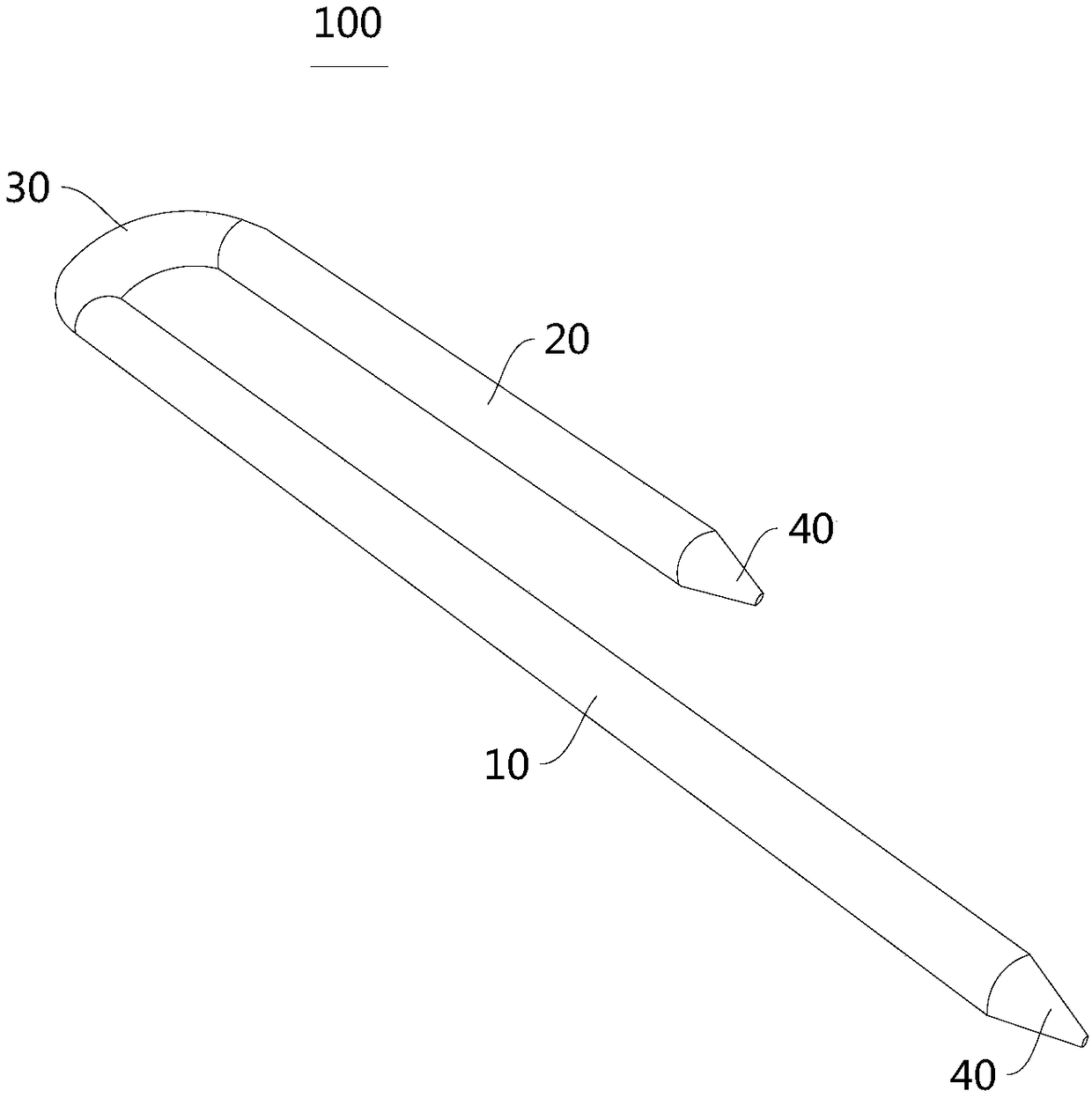

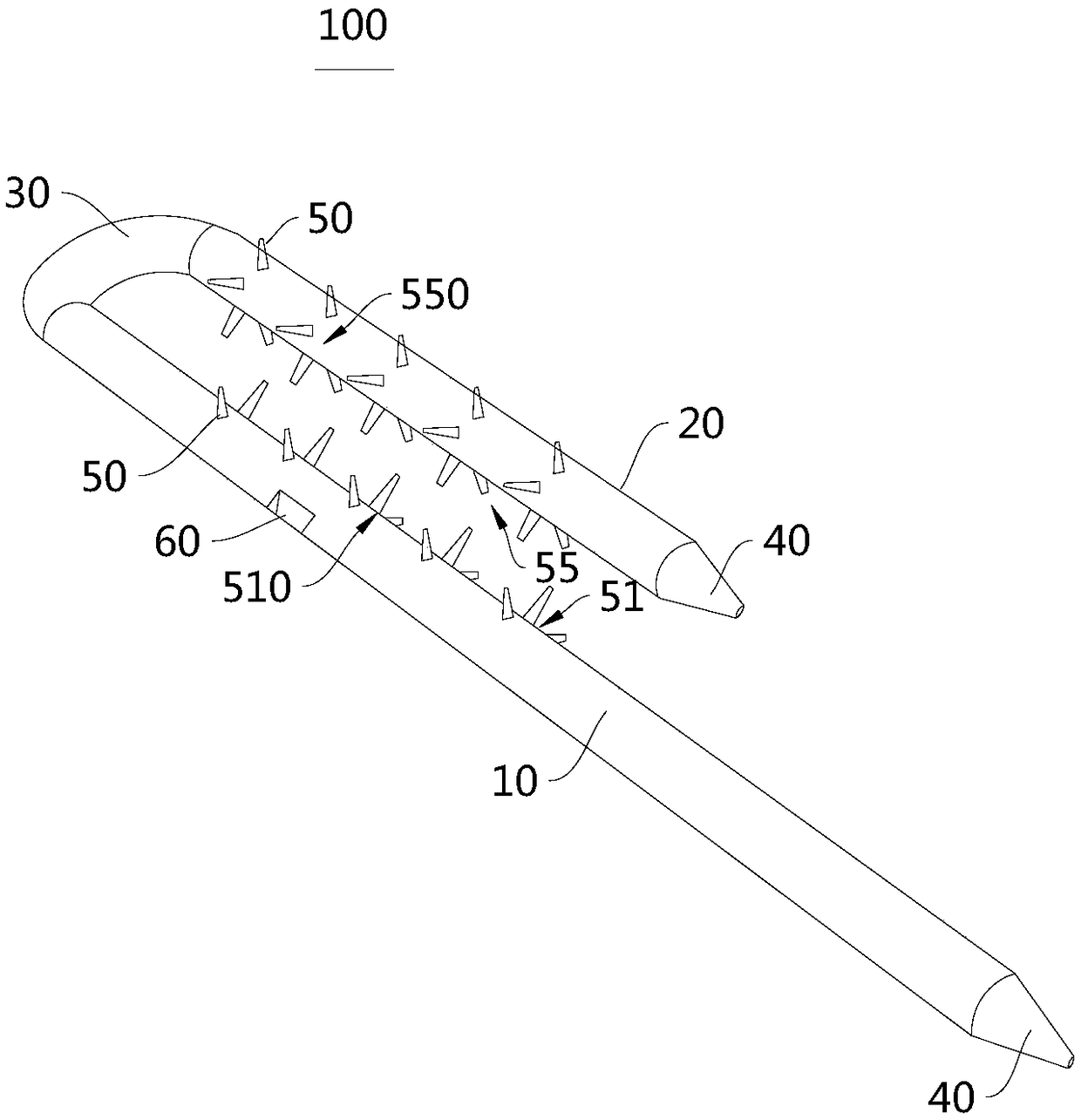

Eta-shaped nail for coral and application of eta-shaped nail

ActiveCN109441928AReduce the chance of sheddingImprove survival rateClimate change adaptationStaplesMedicineHermatypic coral

The invention provides an eta-shaped nail for coral and application of the eta-shaped nail, and belongs to the technical field of ecological artificial repair of coral reefs. The eta-shaped nail for the coral comprises a long foot, a short foot and a transition section; the two ends of the transition section are connected with the long foot and the short foot correspondingly to form an eta shape,and sharp head parts are arranged at the end, away from the transition section, of the short foot and the end, away from the transition section, of the long foot correspondingly. The eta-shaped nail for the coral is simple in structure and low in cost, is used for bottom sowing transplantation of the hermatypic coral, can effectively stabilize and fix the hermatypic coral transplanted on the coralreef bottoms or the reefs, tissue death of the coral due to rotational friction is reduced, the coral falling-off rate is decreased greatly, and the coral survival rate is increased significantly.

Owner:海南珊海海洋科技有限公司

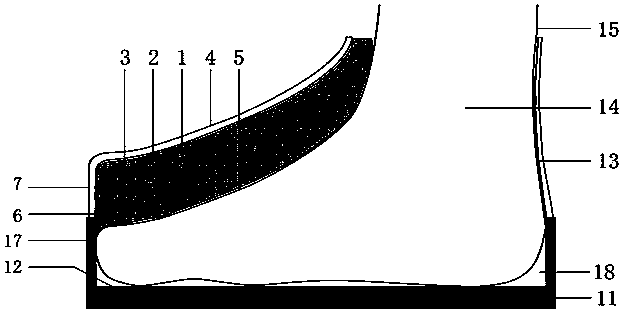

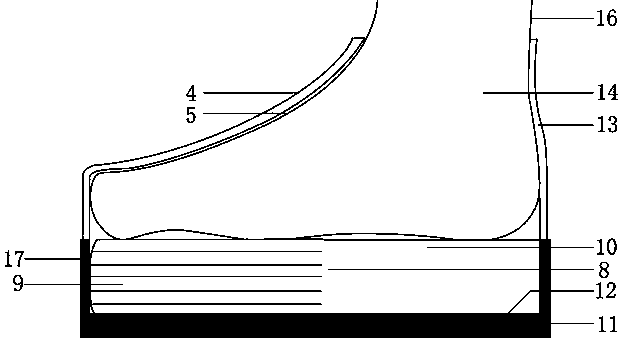

Shoe pads and method for assorting shoe pads with shoes

InactiveCN103734990AAlleviate the problem of high and thick walking board feetImprove one tall and one shortSolesInsolesEngineeringCrowds

Owner:姜德谦

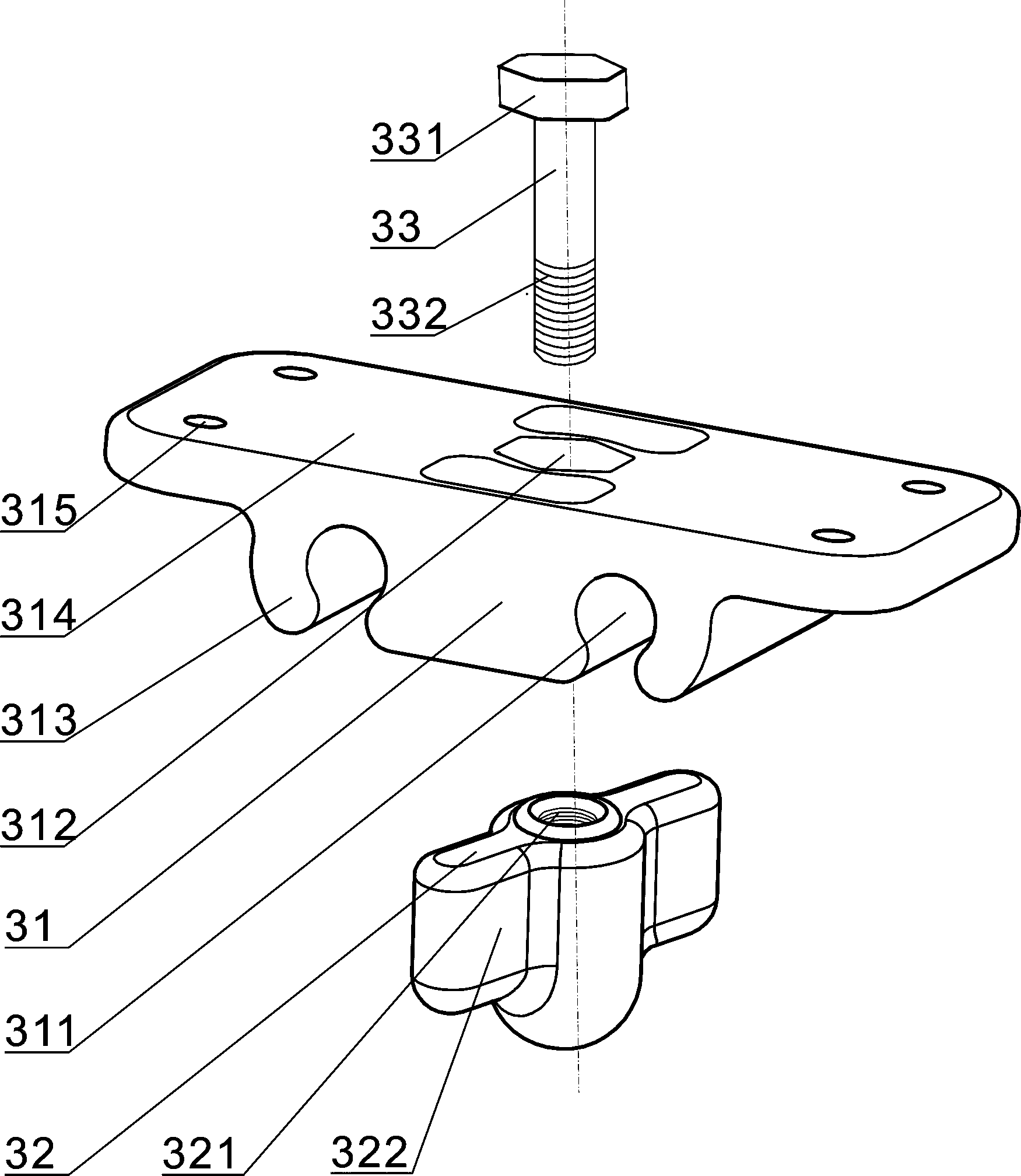

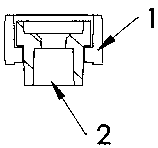

A storage box connecting piece for an instrument board

InactiveCN109747548AExtended service lifeHigh strengthPassenger spaceEngineeringMechanical engineering

A storage box connecting piece for an instrument board is composed of a shaft component (1) and a clamping piece (2). The features are that the shaft component (1) is an integrated injection molding part and is composed of a mounting plane (3) and a shaft arm (4); the shaft arm (4) is arranged in the middle of the plane (3), and mounting holes (5) are formed in the four corners of the plane (3); ashaft hole (6) is formed in the top end of the shaft arm (4), and a clamping piece (2) is arranged in the shaft hole (6) in a tight fit mode. The shaft arm (4) is L-shaped, and the L-shaped short foot is arc-shaped; the shaft hole (6) is arranged at the top end of the L-shaped long foot of the shaft arm (4), and the shaft hole (6) and the arc share the center of a circle. The storage box connecting piece is simple in structure, convenient to install and machine, and high in forming rate; direct contact between the shaft hole and the storage box in the using process is prevented through the clamping piece, and the service life of the shaft component is prolonged.

Owner:丹阳市佳洮车辆附件厂

Integrated automatic production equipment based on stem guide wire shaping and LED light bar welding

ActiveCN105345470BFacilitate automated processing operationsEasy to operateOther manufacturing equipments/toolsCircular discReducer

The invention discloses full-automatic production equipment based on stem guide wire shaping and LED light strip welding integration. The full-automatic production equipment comprises a main bottom plate, a platen and an upper bracket, wherein the upper end of the main bottom plate supports the platen through four thick bracket legs. A discharging mechanism and a buffering conveying mechanism are arranged on the left and the right of the side surface of the platen respectively, and a feed mechanism is arranged at the end of the buffering conveying mechanism. The platen is provided with a gap divider. An index plate rotates anticlockwise and is provided with a stem clamp. The main bottom plate is provided with a speed reducer, a station main shaft and a cam mechanism. A stem locating mechanism, a long foot arranging mechanism, a short foot poking mechanism, a 45-degree long foot poking assembly mechanism, a 45-degree short foot poking assembly mechanism, a foot straightening mechanism, an LED light strip shearing and conveying mechanism, an automatic LED light strip rotating and conveying mechanism and a welding mechanism are sequentially arranged on the platen from the front end of the feed mechanism and surround the index plate. The full-automatic production equipment is high in automation degree, high in welding and shaping efficiency and high in shaping accuracy.

Owner:南通睿博电器有限公司

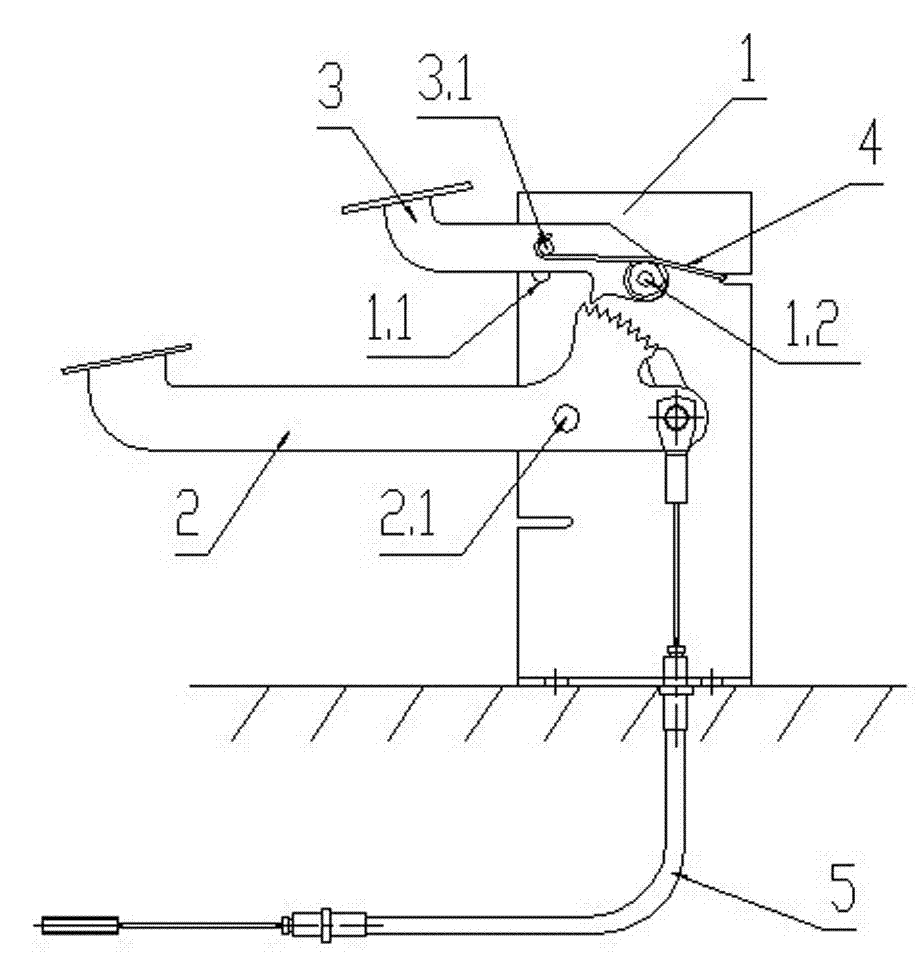

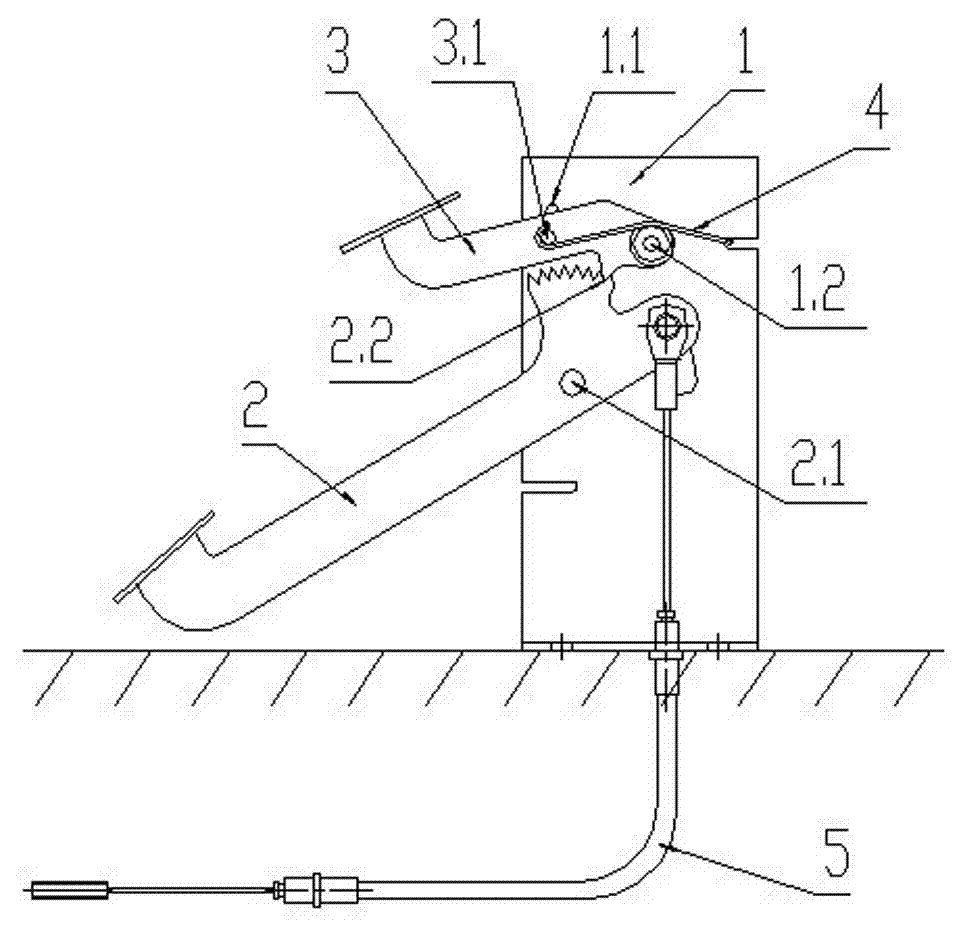

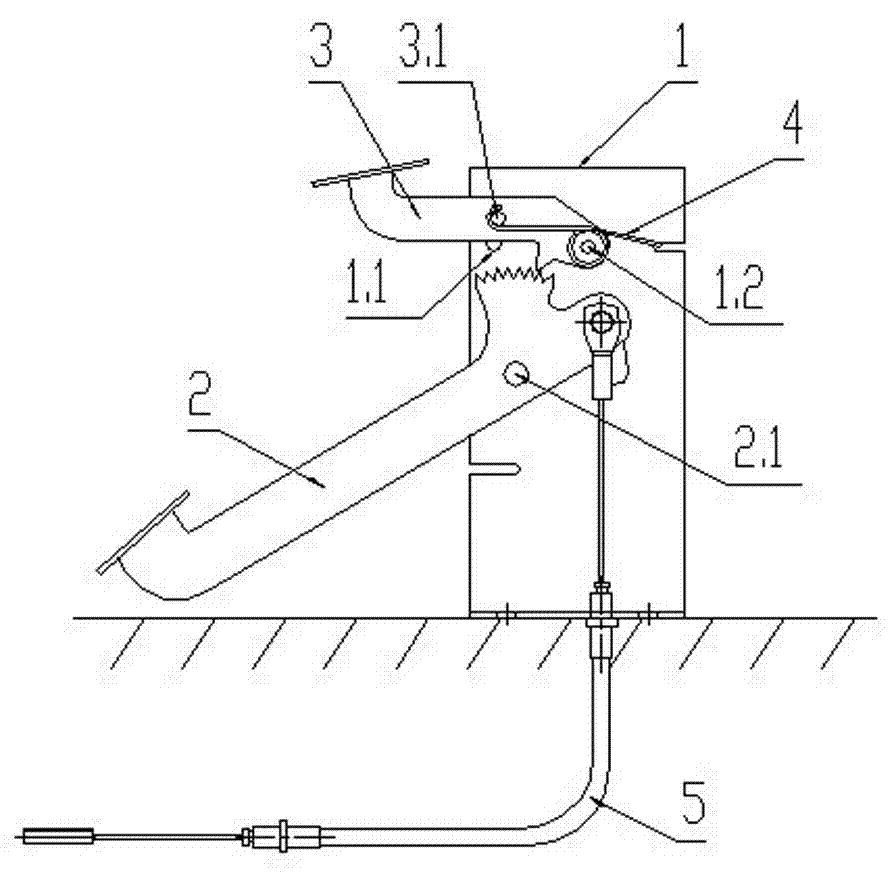

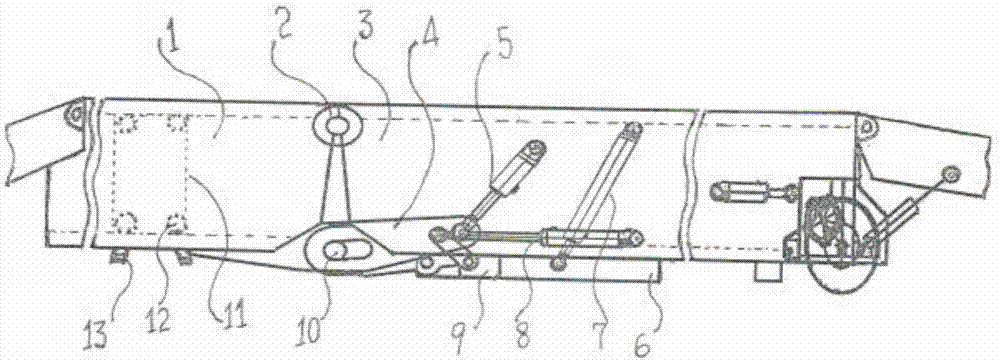

Brake retaining device of electric sweeper

InactiveCN102846277ASimple structureEasy to manufactureMachine detailsFloor sweeping machinesEngineeringCantilever

The invention discloses a brake retaining device of an electric sweeper, which comprises a bracket, a long foot bar, a short foot bar, a spring and an inhaul cable. A right end of the long foot bar is connected with the inhaul cable, and the long foot bar is hinged with the bracket through a pin to form a lever type brake mechanism. The short foot bar is installed on the long foot bar through a mandrel and a hinge pin, the downside of the short foot bar is provided with a ratchet to mesh with a fan-shaped ratchet wheel raised on the long foot bar; and the short foot bar of a cantilever keeps the position under the action of the inhaul cable and locks the long foot bar, therefore the purpose of parking after brake is realized. The integrative installing structure of the long foot bar and the short foot bar is located in the same one foot control scale, when the long foot bar is stepped to carry out the brake, the short foot bar also can be stepped; the brake retaining device is convenient to operate, good in timeliness, likely to lock, and stable and reliable in parking. The invention is applicable to be matched with various sized sweepers as well as ordinary locomotives.

Owner:江苏路驰洁环保车业有限公司

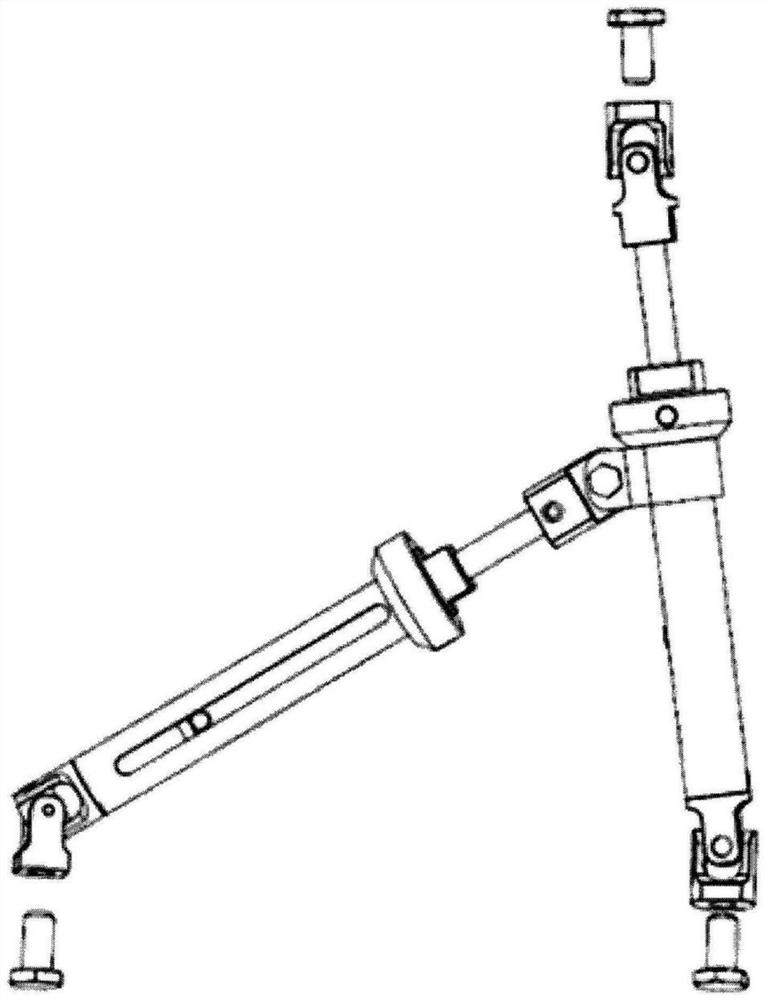

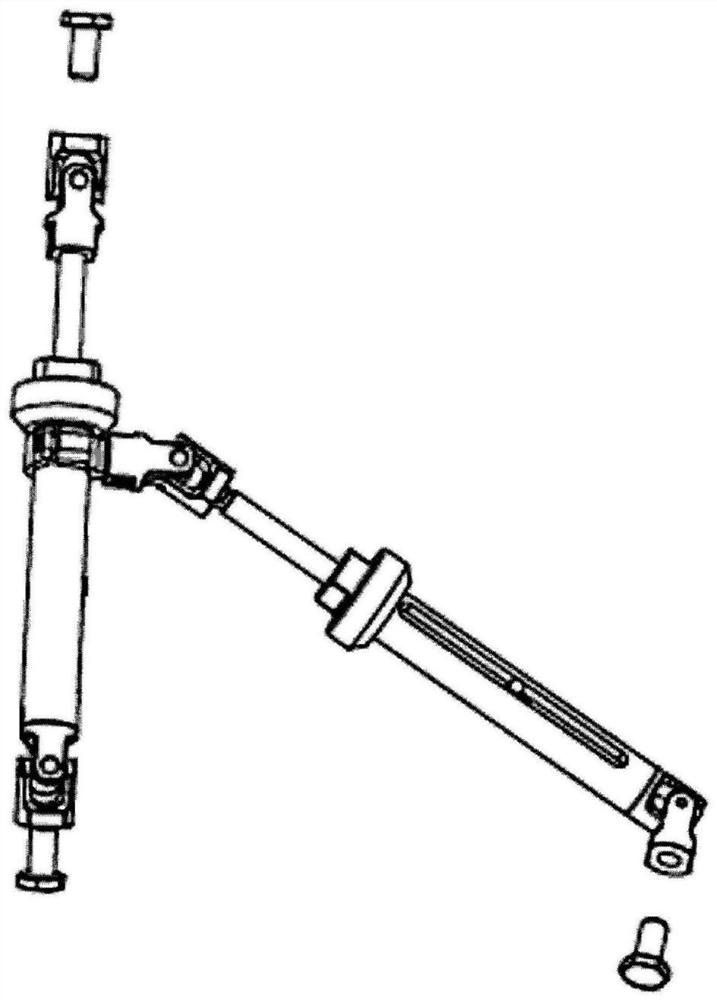

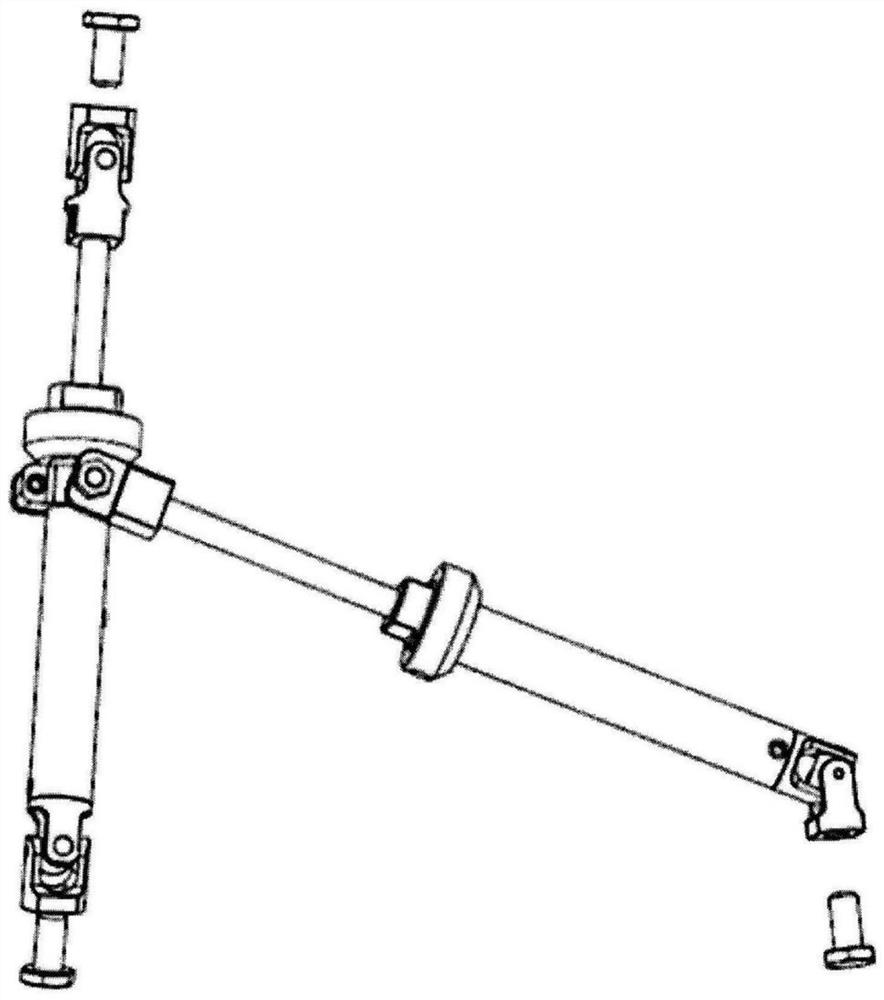

Herringbone retainer

The chevron anchor basically consists of two rings connected to each other by three main structural units called lambda modules, said rings having at least double rows of holes. There are four different lambda modules, two of which are base types and the others are subclasses of base types. In the first basic type there are three ball joints at the ends, a simple swivel joint connecting the long foot to the short foot, and two screw-nut pairs for changing the length of the foot. In the second basic type there are two ball joints at the end of the long feet, two universal joints at each end of the short feet, and two screw-nut pairs varying the length of the feet. By using only one type of lambda module it is possible to set the anchor in 512 different ways.

Owner:易卜拉欣丹尼兹阿卡利

Foot rest component

InactiveCN102490444AGuaranteed uptimeGood effectLamination ancillary operationsLaminationProduction lineEngineering

The invention provides a foot rest component, which is used for placing a pressing plate of a hot press in production line of fire-proof plates. The foot rest component comprises a long foot plate, a medium foot plate and a short foot plate, wherein the long foot plate is arranged close to a machine plate frame; the medium foot plate is arranged on the outer side of the long foot plate; and the short foot plate is arranged on the outer side of the medium foot plate. The foot rest component has the advantages of operation stability, good effect, safety, reliability and the like.

Owner:SUZHOU XINXIELI MACHINE MFG

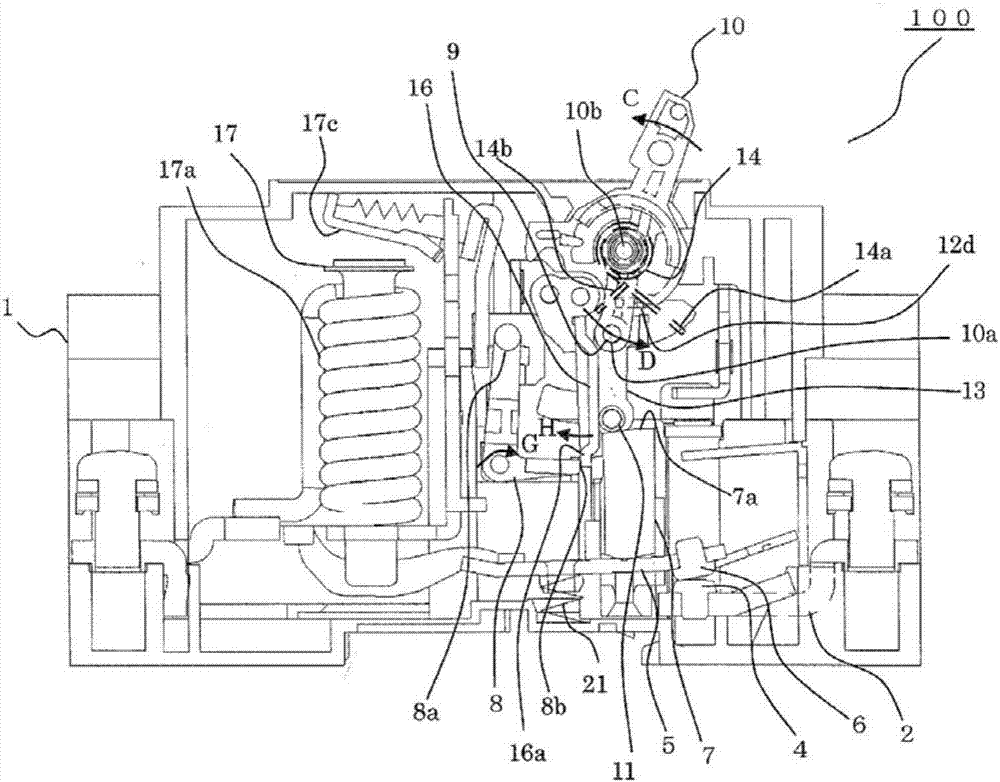

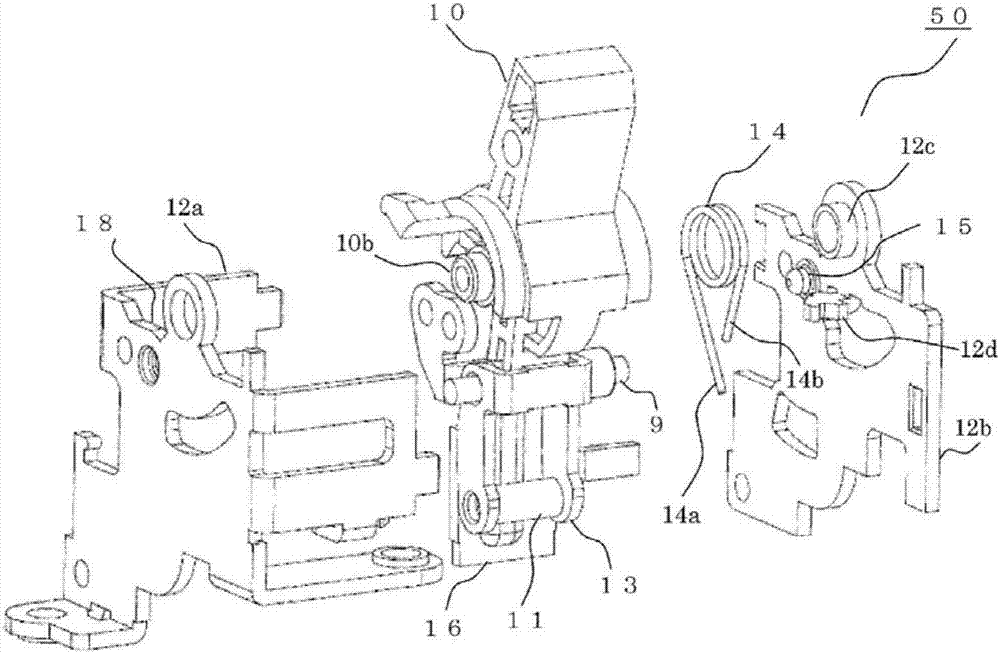

circuit breaker

ActiveCN105378888BLow costReduce trip loadSwitches with electromagnetic releaseProtective switch operating/release mechanismsElectrical conductorMiniaturization

The present invention provides a circuit breaker that does not require additional components, is compatible with automatic assembly, and realizes miniaturization and stable operation. The circuit breaker of the present invention is characterized in that it has: a pressure plate that moves the movable contact conductor to engage the movable contact with the fixed contact; On and off operation to engage with the pressure plate, overcome the pressure of the separation spring, press the pressure plate down, and lift the pressure plate by the pressure of the separation spring through the release of the trip lever; disconnecting the trip spring, which is a torsion spring having a long foot and a short foot, and held at a spring locking shaft corresponding to the rotation shaft of the manual handle; and an engaging protrusion, which is provided on the Just below the spring locking shaft, lock the long leg and short leg of the off trip spring in a state of intersecting each other, and the long leg is set to engage with the link pin inserted through the manual handle. The length of the short foot is set to a length that does not engage with the above-mentioned link pin.

Owner:MITSUBISHI ELECTRIC CORP

Stainless steel fully enclosed marble lock

The invention discloses a stainless steel totally-enclosed spring lock, comprising a lock head, a lock beam, a lock latch and an alarm and the like, wherein the lock beam is treated by quenching; the lock latch is made of thickened type stainless steel square tube with good quality and high strength; an inner container is chained in the whole length of the square tube and is also made of thickened type square tube; and stainless steel cover plates at the two ends are totally enclosed by full welding, so that the performances such as rust prevention, shearing resistance, prying resistance, sawing resistance and smashing resistance of the stainless steel totally-enclosed spring lock are better. A self-locking part adopts combination of a stopping sleeve with a small upper part and a large lower part, a steel ball retainer, steel balls and a spring; when in unlocking, the lock beam is ejected automatically without separating from the lock latch; and a short foot of the lock beam is aligned to a hole position of the lock latch to press downwards and lock automatically. Therefore, the stainless steel totally-enclosed spring lock is flexible and convenient to use.

Owner:蚌埠格识知识产权运营有限公司

Manufacturing process for wooden tray

InactiveCN108381723AIncrease the carrying weightHigh strengthStapling toolsWood treatment detailsEngineeringShort foot

The invention discloses a manufacturing process for a wooden tray. The manufacturing process comprises the following steps that boards and foot piers are selected, wherein the boards and the foot piers are checked by a board flaw detector to be qualified; the boards which are used as a supporting board are placed on a workbench in sequence, two parallel connecting boards are placed below the boards and perpendicular to the boards, and gun nails are used for fixation from top to bottom; the supporting board is taken up, the foot piers are placed on the corresponding positions of the workbench in sequence, and the long foot piers are fixed under the supporting board through the gun nails; and then the short foot piers are fixed under the connecting boards through the gun nails, V-shaped grooves are formed in the back faces of the two ends of a reinforcing surrounding board so that the two ends of the reinforcing surrounding board can form a square frame capable of containing the short foot piers in a surrounding mode, and the two short foot piers on the same side of each connecting board are correspondingly accommodated in the square frame of the reinforcing surrounding board and aretransversely fixed through the gun nails. The wooden tray made by the manufacturing process for the wooden tray is strong and firm, and good in bearing performance.

Owner:浙江林达包装科技股份有限公司

Efficient extending posture adjusting movable trestle

InactiveCN107448210AEasy to move and installFlexible shiftUnderground chambersTravelling bridgesTunnel constructionShort foot

The invention discloses an efficient extending posture adjusting movable trestle. To overcome the defects that the existing tunnel construction span is small, moving is difficult and the efficiency is low, each row of main bridges of the efficient extending posture adjusting movable trestle comprises main bridge front sections and main bridge rear sections. Main bridge connecting mechanisms are arranged on the upper portions of the connecting positions of the main bridge front sections and the main bridge rear sections, posture adjusting arms are arranged on the lower portions of the connecting positions of the main bridge front sections and the main bridge rear sections, and the posture adjusting arms are connected with arm oil cylinders. The front portions of the main bridge rear sections are provided with long supporting feet and short supporting feet, and the long supporting feet and the short supporting feet are connected with long-foot oil cylinders and short-foot oil cylinders correspondingly. Movable supports are arranged between the two rows of main bridges. The efficient extending posture adjusting movable trestle is used for tunnel construction, large span line production and continuous construction can be achieved, automatic architecture moving and posture automatic adjusting and controlling are achieved, installation and moving are easy, moving is flexible, architecture is rapid, the efficiency is high, the structure is compact, the occupied area is small, the manufacturing and using cost is low, and the efficient extending posture adjusting movable trestle is particularly suitable for construction of a single track tunnel with a narrow space under a complex geology condition.

Owner:HUNAN WUXIN MACHINERY

A device with weighing and automatic feeding functions

ActiveCN103407798BAvoid lostReduce labor intensityLarge containersLoading/unloadingEngineeringUltimate tensile strength

A device with weighing and automatic blanking functions comprises a control device, a conveying device, a blanking door, communication lines, push rod hinge parts, an electric push rod, a door hinge, a hopper, a short foot plate, a weighing sensor, a hopper seat, foot wheels, a long foot plate and a connection plate. The device with the weighing and automatic blanking functions is characterized in that the short foot plate and the long foot plate are arranged at the bottom of the hopper, the weighing sensor is connected to the lower portions of the short foot plate and the long foot plate and connected with the hopper seat, the connection plate is arranged on the long foot plate, the foot wheels are arranged on the hopper seat, the conveying device is arranged below the hopper and positioned on the hopper seat, the hopper is connected with the blanking door through the door hinge, the blanking door is connected with the electric push rod through the push rod hinge part, the electric push rod is connected with the connection plate through the push rod hinge part, and the control device is connected with the weighing sensor and the electric push rod through the communication lines. The device has the weighing and automatic blanking functions, no material is lost in use, and labor intensity of operators is reduced.

Owner:JIANGXI GUANGMING INTELLIGENT TECH CO LTD

Building internal decoration weaving device

The invention discloses a building internal decoration weaving device. A long foot yarn guide device and a short foot yarn guide device of the weaving device are overlapped in a one-to-one corresponding mode. The upper ends of the two yarn guide devices are clamped in a clamping groove. Tension springs are connected between the two yarn guide devices and a vertical shaft. The inner sides of the upper ends of the two yarn guide devices are provided with hooks hooking a fixed wire. An ejecting protruding block on the outer side of the upper end of the short foot yarn guide device is provided with a first working face. An ejecting protruding block on the outer side of the upper end of the long foot yarn guide device is provided with a second working face. A yarn adjusting plate is assembled on a machine frame in a sliding mode through a horizontal shaft. A compressed spring for pushing the horizontal shaft forwards and making the yarn adjusting plate matched with the first horizontal plane is arranged between the horizontal shaft and the machine frame. A drive mechanism for driving the horizontal shaft to overcome the compressed spring force to move backwards and making the horizontal shaft separated from the first horizontal plane and matched with the second horizontal plane is arranged on the machine frame. A receding groove is formed in the position, corresponding to the matched position of the first horizontal plane and the yarn adjusting plate, of the second horizontal plane. The short foot yarn guide device and the long foot yarn guide device are arranged, the two yarn guide devices can carry yarns of different colors, and in this way, colorful embroidered fabrics can be woven.

Owner:NANYANG INST OF TECH

A kind of breeding method of Jinling chicken

ActiveCN104430180BFast growthStable traitsFood processingAnimal feeding stuffBest diseaseBroiler chick

The invention relates to the field of poultry breeding, in particular to a cultivating method of Jinling broiler. The method includes the steps of 1, subjecting dwarf spotty chicken to selfing, crossing fixation and breeding to obtain first male parents; subjecting grain-saving yellow chicken to selfing, crossing fixation and breeding to first female parents; 2, subjecting the first male parents and the first female parents to hybridizing, crossing fixation and breeding to obtain second female parents; subjecting fast-growth spotty chicken to selfing, crossing fixation and breeding to obtain second male parents; 3, subjecting the second male parents and the second female parents to hybridizing, and performing closed breeding for at least six generations to obtain the Jinling broiler. The Jinling broiler cultivated by the cultivating method has short feet, eats fewer grains, grows fast, has good disease resistance and has high chicken and egg nutritional value.

Owner:广西金陵农牧集团有限公司

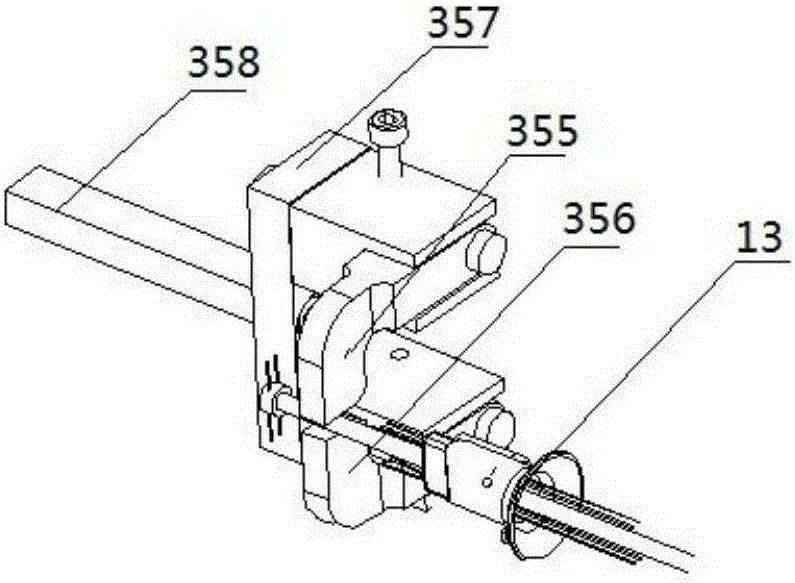

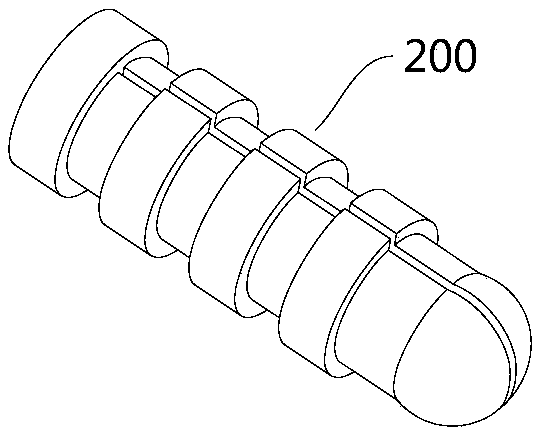

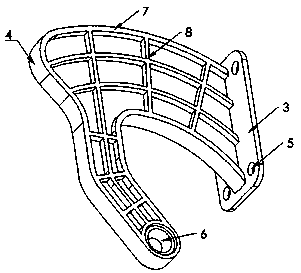

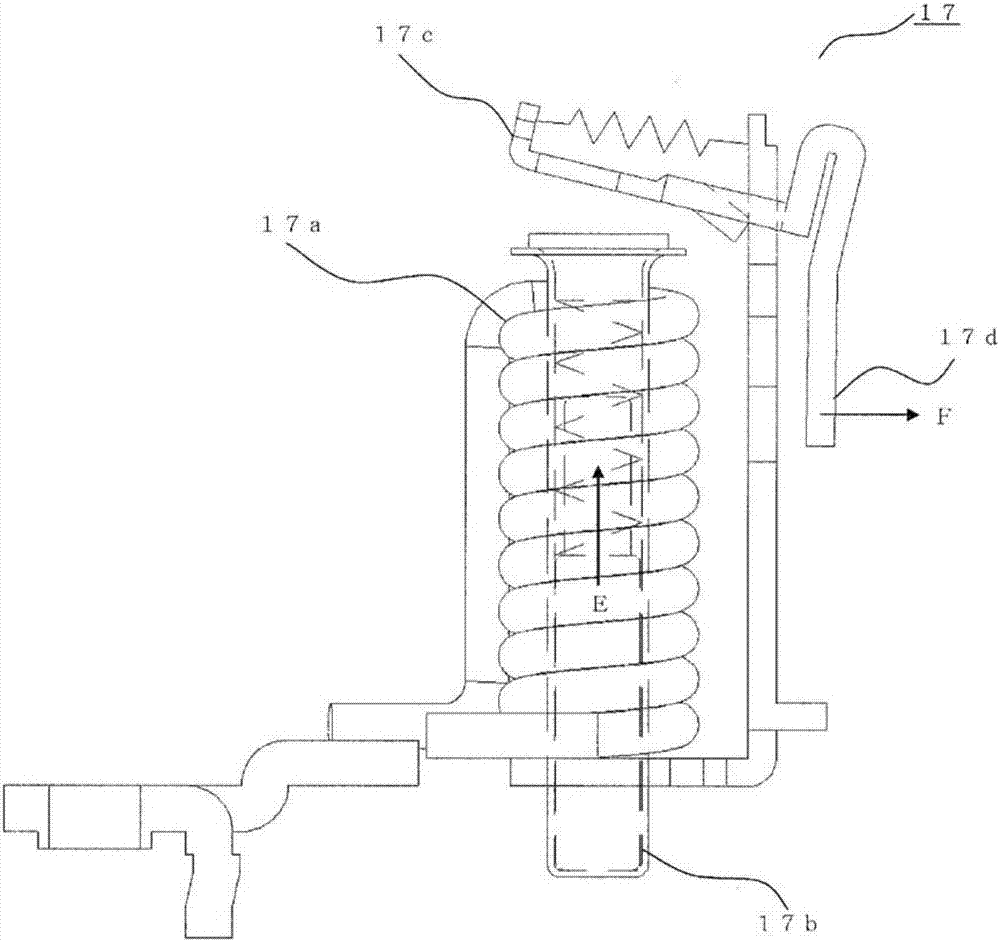

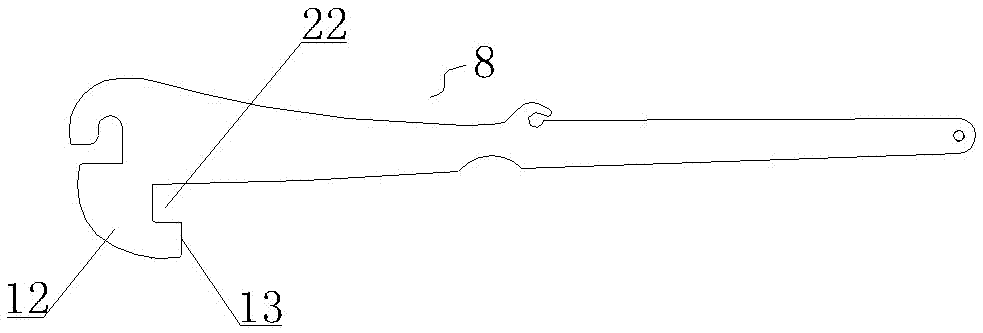

Short-foot automatic sealing method and device for screw type fluorescent lamp tube

InactiveCN101125728BQuality improvementImprove yieldVessels or leading-in conductors manufactureGlass reforming apparatusShort rootProduction rate

The invention relates to an automatic sealing method for spiral fluorescent lamp tube root and equipment thereof, aiming at providing a method and equipment thereof to produce short root lamp tubes and have high production rate, good quality and high automatization. The technical proposal is of an automatic sealing method for short tube root of the spiral fluorescent lamp tube. The method is divided into the steps: 1. prelocating the tube root; 2. taking the spiral peripheral part of the lamp tube as a handle part when sintering; 3. locating the space position of the lamp tube root to be sintered; 4. preheating; 5. locating a core column in the tube root; 6. sintering; 7. repeating the processes to process a second tube root. The automatic sealing equipment for short tube root of the spiral fluorescent lamp tube comprises a frame with a plurality of working stations. The frame is equipped with a main shaft, the upper end of which is fixed with a plurality of an externally grabbing-typed sealing clamper. The main shaft is driven by a driving mechanism and is provided with a control device. The working stations comprise tubes of material feeding location, preheating and sintering and each station is configured with a corresponding operation device.

Owner:HANGZHOU YUZHONG GAOHONG LIGHTING ELECTRICAL

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com