Foot roll support frame with multi-section short-side foot rolls

A segmented, support frame technology, applied in the field of support frames, can solve the problems of not being able to improve the inhibition of foot rolls, achieve the effects of improving production safety and avoiding steel leakage accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

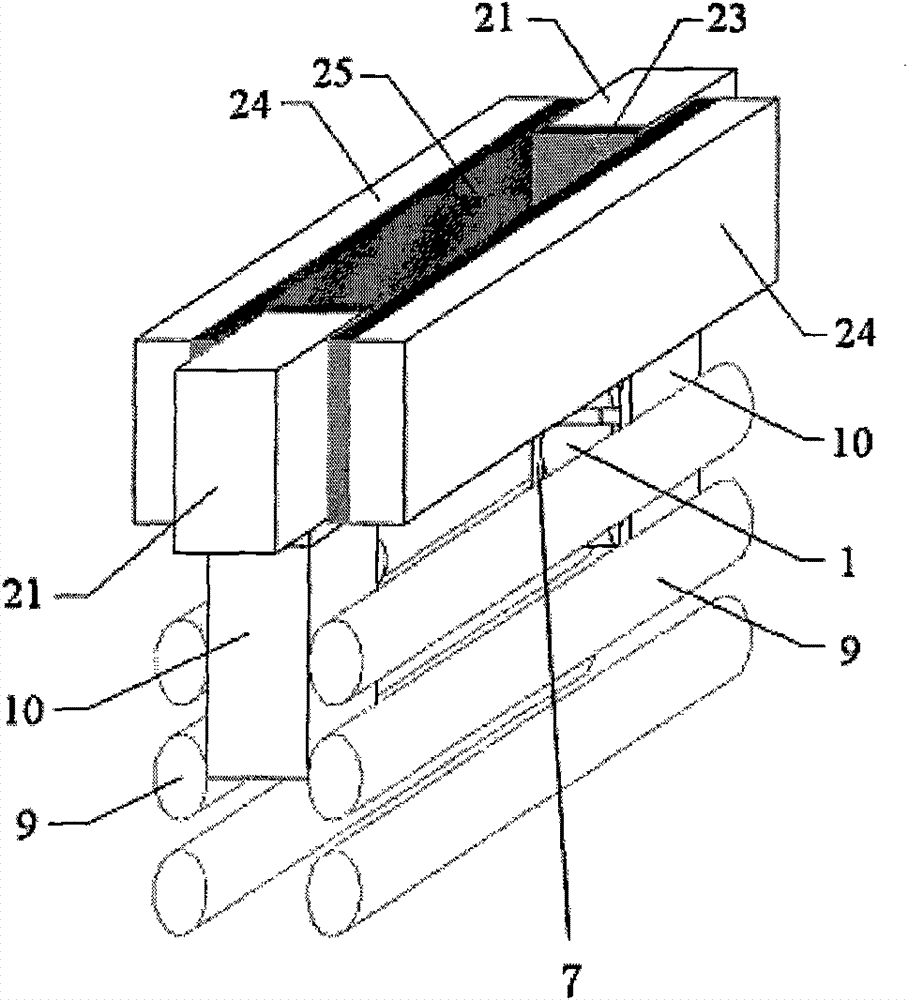

[0027] Below, according to Figure 4 ~ Figure 8 The specific structure and beneficial effect of the foot roller supporting frame (hereinafter referred to as "foot roller supporting frame") with multiple segmented short side foot rollers of the present invention will be described.

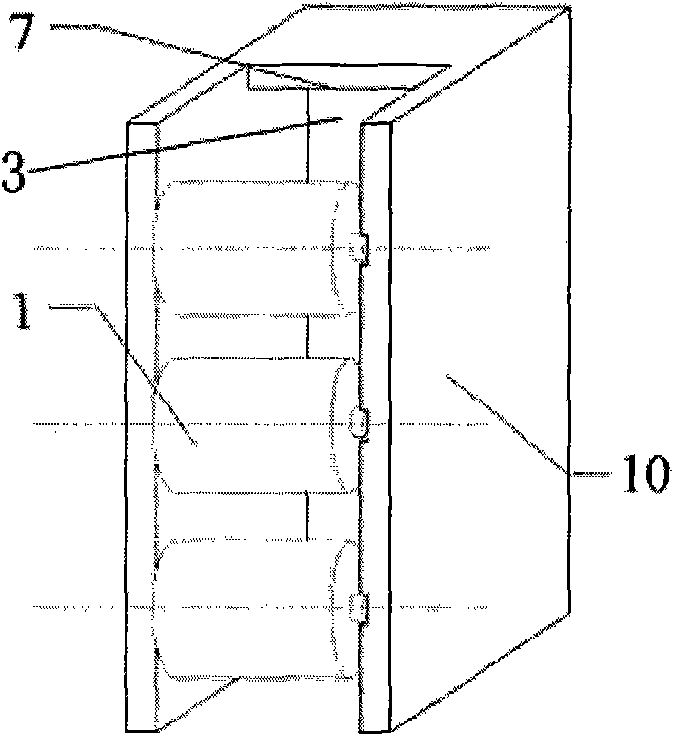

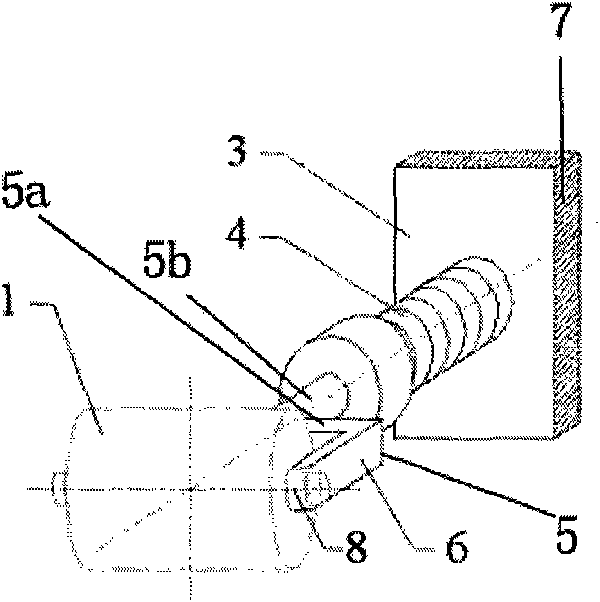

[0028] Figure 4 It is a partially cutaway perspective view showing the front end side of the right frame side wall 10b of the foot roller support frame of the present invention. Such as Figure 4As shown, the foot roller support frame 7 of the present invention is composed of a left frame side wall 10a, a right frame side wall 10b and a bracket side wall 11 integrated with the rear end sides of these left and right frame side walls. More than three (at least three, shown as three) foot roller assemblies g are arranged in sequence from top to bottom on the wall surface 3, and each foot roller assembly g includes: short-side foot roller 1; foot roller support part 5, which The arm is supported by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com